Are you a seasoned Injection Molding Operator seeking a new career path? Discover our professionally built Injection Molding Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

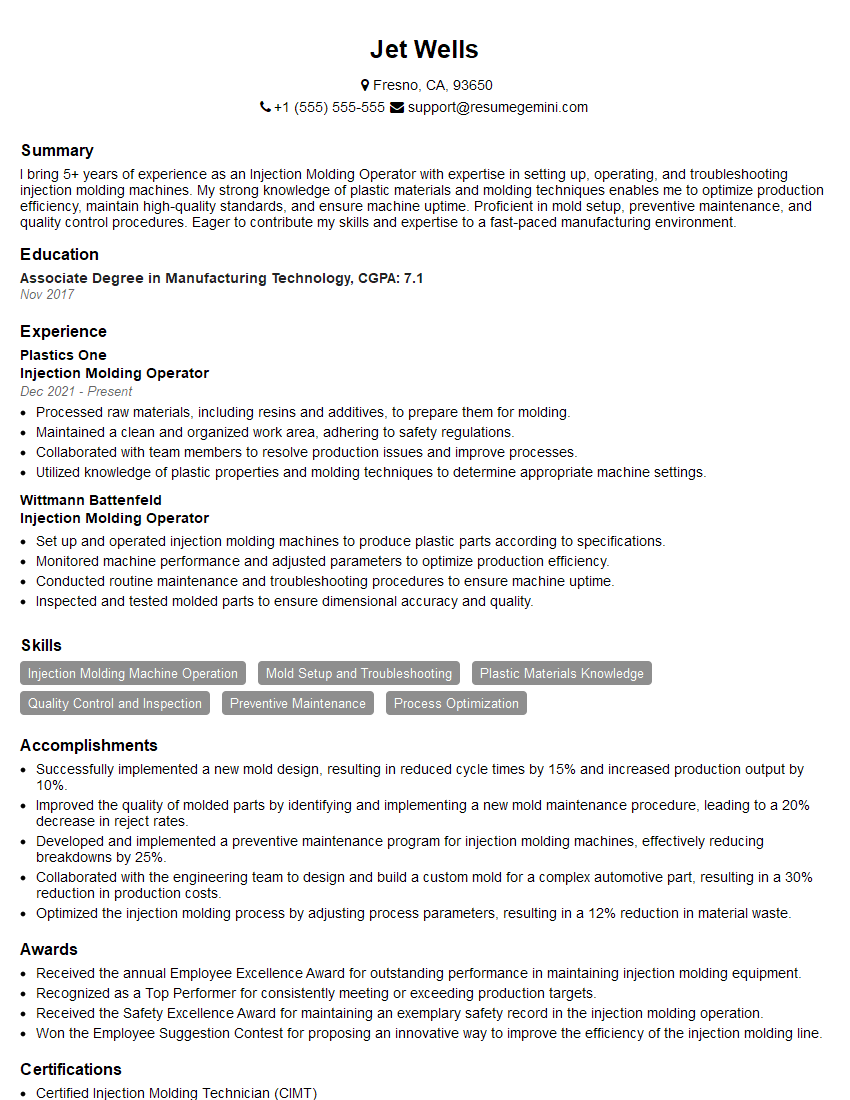

Jet Wells

Injection Molding Operator

Summary

I bring 5+ years of experience as an Injection Molding Operator with expertise in setting up, operating, and troubleshooting injection molding machines. My strong knowledge of plastic materials and molding techniques enables me to optimize production efficiency, maintain high-quality standards, and ensure machine uptime. Proficient in mold setup, preventive maintenance, and quality control procedures. Eager to contribute my skills and expertise to a fast-paced manufacturing environment.

Education

Associate Degree in Manufacturing Technology

November 2017

Skills

- Injection Molding Machine Operation

- Mold Setup and Troubleshooting

- Plastic Materials Knowledge

- Quality Control and Inspection

- Preventive Maintenance

- Process Optimization

Work Experience

Injection Molding Operator

- Processed raw materials, including resins and additives, to prepare them for molding.

- Maintained a clean and organized work area, adhering to safety regulations.

- Collaborated with team members to resolve production issues and improve processes.

- Utilized knowledge of plastic properties and molding techniques to determine appropriate machine settings.

Injection Molding Operator

- Set up and operated injection molding machines to produce plastic parts according to specifications.

- Monitored machine performance and adjusted parameters to optimize production efficiency.

- Conducted routine maintenance and troubleshooting procedures to ensure machine uptime.

- Inspected and tested molded parts to ensure dimensional accuracy and quality.

Accomplishments

- Successfully implemented a new mold design, resulting in reduced cycle times by 15% and increased production output by 10%.

- Improved the quality of molded parts by identifying and implementing a new mold maintenance procedure, leading to a 20% decrease in reject rates.

- Developed and implemented a preventive maintenance program for injection molding machines, effectively reducing breakdowns by 25%.

- Collaborated with the engineering team to design and build a custom mold for a complex automotive part, resulting in a 30% reduction in production costs.

- Optimized the injection molding process by adjusting process parameters, resulting in a 12% reduction in material waste.

Awards

- Received the annual Employee Excellence Award for outstanding performance in maintaining injection molding equipment.

- Recognized as a Top Performer for consistently meeting or exceeding production targets.

- Received the Safety Excellence Award for maintaining an exemplary safety record in the injection molding operation.

- Won the Employee Suggestion Contest for proposing an innovative way to improve the efficiency of the injection molding line.

Certificates

- Certified Injection Molding Technician (CIMT)

- Certified Plastic Processing Technician (CPPT)

- Certified Mold Maker (CMM)

- ISO 9001 Lead Auditor

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Injection Molding Operator

- Highlight your experience and proficiency in injection molding machine operation and setup.

- Demonstrate your knowledge of plastic materials, molding techniques, and quality control procedures.

- Emphasize your ability to troubleshoot and resolve production issues effectively.

- Showcase your commitment to maintaining a safe and efficient work environment.

- Provide specific examples and quantifiable results to support your claims.

Essential Experience Highlights for a Strong Injection Molding Operator Resume

- Successfully set up and operated injection molding machines, achieving optimal production efficiency.

- Consistently monitored machine performance, identified potential issues, and adjusted parameters to maximize output.

- Carried out regular maintenance and troubleshooting procedures, minimizing downtime and ensuring machine reliability.

- Rigorously inspected and tested molded parts, ensuring dimensional accuracy and adherence to quality specifications.

- Prepared raw materials, including resins and additives, following established procedures.

- Maintained a clean and organized work environment, adhering to safety regulations and industry best practices.

- Effectively collaborated with team members to overcome production challenges and implement process improvements.

Frequently Asked Questions (FAQ’s) For Injection Molding Operator

What are the key skills and qualifications required for an Injection Molding Operator?

Essential skills include proficiency in injection molding machine operation, mold setup and troubleshooting, knowledge of plastic materials, quality control and inspection techniques, preventive maintenance, and process optimization.

What are the primary responsibilities of an Injection Molding Operator?

Key responsibilities involve setting up and operating injection molding machines, monitoring machine performance, conducting maintenance and troubleshooting, inspecting and testing molded parts, and maintaining a safe and efficient work environment.

How can I improve my resume as an Injection Molding Operator?

Enhance your resume by highlighting your experience, skills, and certifications. Quantify your accomplishments, use action verbs, and proofread carefully before submitting.

What are the career prospects for Injection Molding Operators?

With experience and additional training, Injection Molding Operators can advance to supervisory roles, production management positions, or specialized areas such as mold design or process engineering.

What is the average salary for an Injection Molding Operator?

The average salary for an Injection Molding Operator varies depending on experience, location, and industry. According to the U.S. Bureau of Labor Statistics, the median annual wage for Plastic Molding Machine Operators was $43,560 in May 2022.

What are the job outlook and industry trends for Injection Molding Operators?

The job outlook for Injection Molding Operators is expected to grow in the coming years, driven by the increasing demand for plastic products across various industries. Industry trends include automation, advanced molding techniques, and sustainable manufacturing practices.

What are the challenges and rewards of being an Injection Molding Operator?

Challenges include working in a potentially hazardous environment, managing production pressures, and ensuring product quality. Rewards include job stability, opportunities for career advancement, and the satisfaction of producing tangible products.