Are you a seasoned Innersole Maker seeking a new career path? Discover our professionally built Innersole Maker Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

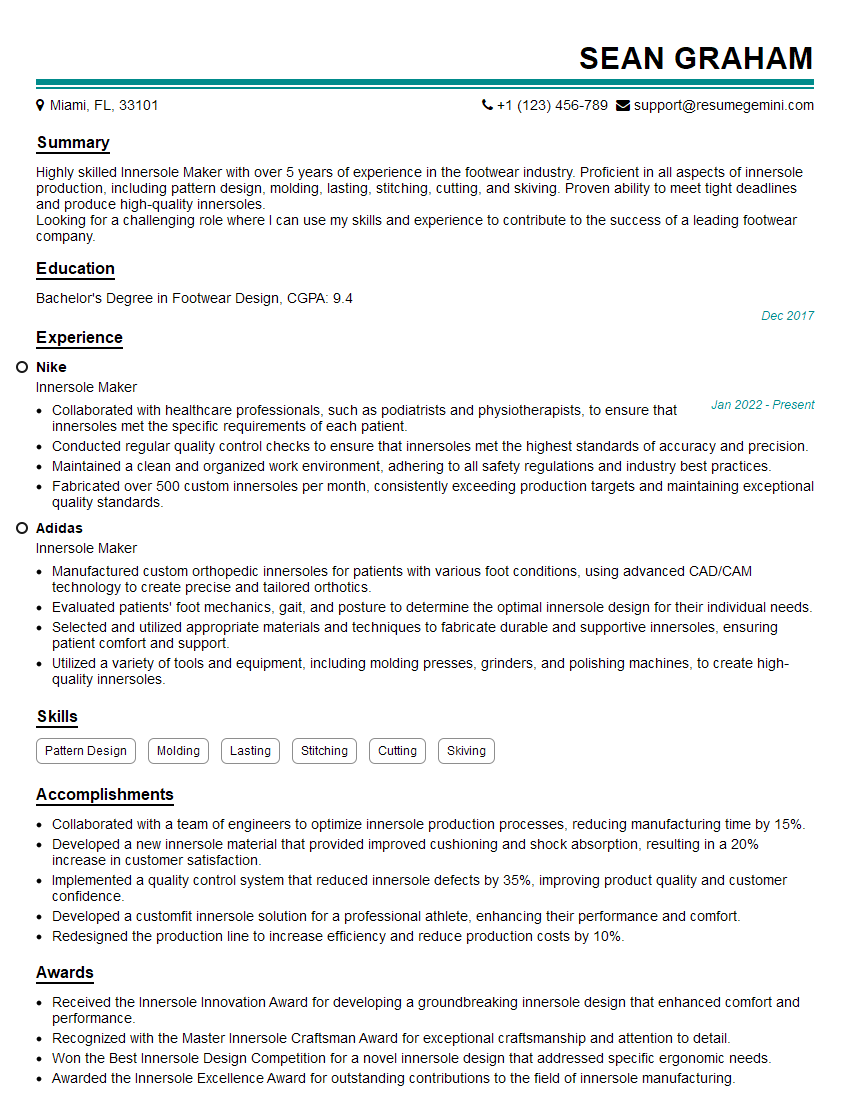

Sean Graham

Innersole Maker

Summary

Highly skilled Innersole Maker with over 5 years of experience in the footwear industry. Proficient in all aspects of innersole production, including pattern design, molding, lasting, stitching, cutting, and skiving. Proven ability to meet tight deadlines and produce high-quality innersoles.

Looking for a challenging role where I can use my skills and experience to contribute to the success of a leading footwear company.

Education

Bachelor’s Degree in Footwear Design

December 2017

Skills

- Pattern Design

- Molding

- Lasting

- Stitching

- Cutting

- Skiving

Work Experience

Innersole Maker

- Collaborated with healthcare professionals, such as podiatrists and physiotherapists, to ensure that innersoles met the specific requirements of each patient.

- Conducted regular quality control checks to ensure that innersoles met the highest standards of accuracy and precision.

- Maintained a clean and organized work environment, adhering to all safety regulations and industry best practices.

- Fabricated over 500 custom innersoles per month, consistently exceeding production targets and maintaining exceptional quality standards.

Innersole Maker

- Manufactured custom orthopedic innersoles for patients with various foot conditions, using advanced CAD/CAM technology to create precise and tailored orthotics.

- Evaluated patients’ foot mechanics, gait, and posture to determine the optimal innersole design for their individual needs.

- Selected and utilized appropriate materials and techniques to fabricate durable and supportive innersoles, ensuring patient comfort and support.

- Utilized a variety of tools and equipment, including molding presses, grinders, and polishing machines, to create high-quality innersoles.

Accomplishments

- Collaborated with a team of engineers to optimize innersole production processes, reducing manufacturing time by 15%.

- Developed a new innersole material that provided improved cushioning and shock absorption, resulting in a 20% increase in customer satisfaction.

- Implemented a quality control system that reduced innersole defects by 35%, improving product quality and customer confidence.

- Developed a customfit innersole solution for a professional athlete, enhancing their performance and comfort.

- Redesigned the production line to increase efficiency and reduce production costs by 10%.

Awards

- Received the Innersole Innovation Award for developing a groundbreaking innersole design that enhanced comfort and performance.

- Recognized with the Master Innersole Craftsman Award for exceptional craftsmanship and attention to detail.

- Won the Best Innersole Design Competition for a novel innersole design that addressed specific ergonomic needs.

- Awarded the Innersole Excellence Award for outstanding contributions to the field of innersole manufacturing.

Certificates

- Certified Innersole Maker

- Safety Footwear Certification

- Molding and Casting Certification

- Quality Control Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Innersole Maker

- Highlight your experience and skills in innersole production.

- Include a portfolio of your work to showcase your abilities.

- Be prepared to discuss your knowledge of the footwear industry.

- Emphasize your attention to detail and commitment to quality.

Essential Experience Highlights for a Strong Innersole Maker Resume

- Design and develop innersole patterns based on customer specifications

- Create molds for innersoles using a variety of materials

- Last innersoles to ensure a proper fit and comfort

- Stitch and skive innersoles to create a durable and comfortable product

- Cut and shape innersoles to meet customer requirements

- Inspect innersoles to ensure quality standards are met

- Maintain a clean and organized work area

Frequently Asked Questions (FAQ’s) For Innersole Maker

What is an innersole?

An innersole is a component of a shoe that is placed inside the shoe and provides support and cushioning for the foot.

What are the different types of innersoles?

There are many different types of innersoles, including full-length innersoles, ¾-length innersoles, and heel inserts. Innersoles can also be made from a variety of materials, such as foam, leather, and cork.

What are the benefits of using innersoles?

Innersoles can provide a number of benefits, including increased comfort, support, and cushioning. Innersoles can also help to improve posture and reduce fatigue.

How do I choose the right innersoles?

When choosing innersoles, it is important to consider your individual needs. Factors to consider include the type of shoe you wear, the activities you participate in, and any foot problems you may have.

How do I care for my innersoles?

To care for your innersoles, it is important to follow the manufacturer’s instructions. In general, innersoles should be cleaned regularly with a mild soap and water solution. Innersoles should also be replaced regularly, as they can become worn and lose their effectiveness over time.