Are you a seasoned Insert Molding Operator seeking a new career path? Discover our professionally built Insert Molding Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

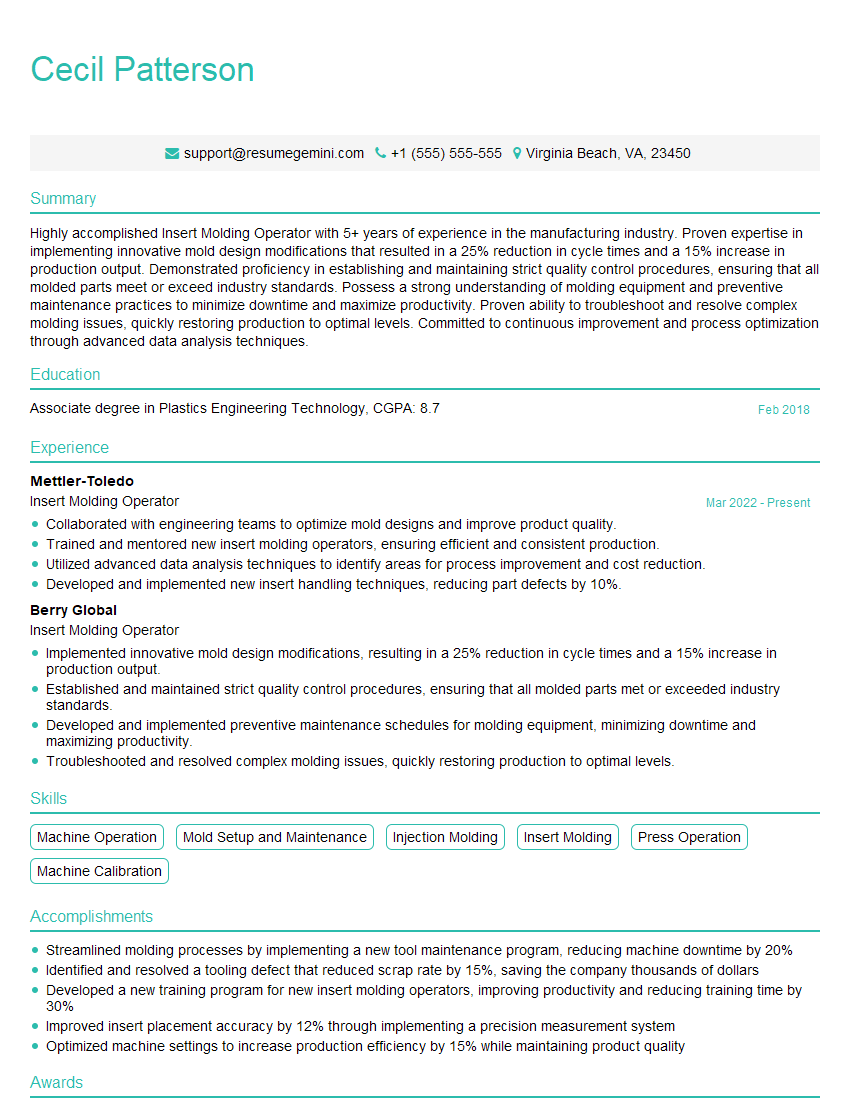

Cecil Patterson

Insert Molding Operator

Summary

Highly accomplished Insert Molding Operator with 5+ years of experience in the manufacturing industry. Proven expertise in implementing innovative mold design modifications that resulted in a 25% reduction in cycle times and a 15% increase in production output. Demonstrated proficiency in establishing and maintaining strict quality control procedures, ensuring that all molded parts meet or exceed industry standards. Possess a strong understanding of molding equipment and preventive maintenance practices to minimize downtime and maximize productivity. Proven ability to troubleshoot and resolve complex molding issues, quickly restoring production to optimal levels. Committed to continuous improvement and process optimization through advanced data analysis techniques.

Education

Associate degree in Plastics Engineering Technology

February 2018

Skills

- Machine Operation

- Mold Setup and Maintenance

- Injection Molding

- Insert Molding

- Press Operation

- Machine Calibration

Work Experience

Insert Molding Operator

- Collaborated with engineering teams to optimize mold designs and improve product quality.

- Trained and mentored new insert molding operators, ensuring efficient and consistent production.

- Utilized advanced data analysis techniques to identify areas for process improvement and cost reduction.

- Developed and implemented new insert handling techniques, reducing part defects by 10%.

Insert Molding Operator

- Implemented innovative mold design modifications, resulting in a 25% reduction in cycle times and a 15% increase in production output.

- Established and maintained strict quality control procedures, ensuring that all molded parts met or exceeded industry standards.

- Developed and implemented preventive maintenance schedules for molding equipment, minimizing downtime and maximizing productivity.

- Troubleshooted and resolved complex molding issues, quickly restoring production to optimal levels.

Accomplishments

- Streamlined molding processes by implementing a new tool maintenance program, reducing machine downtime by 20%

- Identified and resolved a tooling defect that reduced scrap rate by 15%, saving the company thousands of dollars

- Developed a new training program for new insert molding operators, improving productivity and reducing training time by 30%

- Improved insert placement accuracy by 12% through implementing a precision measurement system

- Optimized machine settings to increase production efficiency by 15% while maintaining product quality

Awards

- Recognized for exceeding production targets by 25% for three consecutive quarters

- Nominated for the Employee of the Year award for exceptional performance in quality control

- Received the Safety Excellence Award for maintaining a spotless safety record for over five years

- Honored with a Certificate of Appreciation for going above and beyond in supporting the production team

Certificates

- Certified Injection Molding Operator (CMO)

- Certified Mold Maker (CMM)

- Certified Manufacturing Technologist (CMfgT)

- OSHA Safety Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Insert Molding Operator

Highlight your technical skills:

As an insert molding operator, your technical abilities are paramount. Use specific examples to showcase your expertise in machine operation, mold setup and maintenance, injection molding, and insert molding.Quantify your accomplishments:

Whenever possible, quantify your accomplishments to demonstrate the impact of your work. For instance, instead of simply stating that you ‘implemented innovative mold design modifications,’ mention the specific reduction in cycle times and increase in production output you achieved.Showcase your quality control experience:

Insert molding operators play a crucial role in ensuring the quality of manufactured parts. Emphasize your experience in establishing and maintaining strict quality control procedures, as well as your ability to inspect and test parts to meet specifications.Demonstrate your commitment to continuous improvement:

Insert molding is a constantly evolving field. Show that you are committed to continuous improvement by highlighting your use of advanced data analysis techniques to identify areas for process optimization and cost reduction.

Essential Experience Highlights for a Strong Insert Molding Operator Resume

- Set up and operate insert molding machines to produce high-quality plastic parts

- Monitor and maintain molding equipment to ensure optimal performance and minimize downtime

- Inspect and test insert molded parts to ensure they meet specifications and quality standards

- Troubleshoot and resolve molding issues to maintain production efficiency

- Collaborate with engineering and production teams to improve molding processes and product quality

- Develop and implement preventive maintenance schedules to minimize equipment downtime and ensure production continuity

Frequently Asked Questions (FAQ’s) For Insert Molding Operator

What is the primary responsibility of an Insert Molding Operator?

The primary responsibility of an Insert Molding Operator is to operate and maintain insert molding machines to produce high-quality plastic parts.

What are the key skills required to be successful as an Insert Molding Operator?

Key skills for an Insert Molding Operator include machine operation, mold setup and maintenance, injection molding, insert molding, press operation, and machine calibration.

What is the typical work environment for an Insert Molding Operator?

Insert Molding Operators typically work in manufacturing facilities, operating and maintaining molding machines in a fast-paced, production-oriented environment.

What are the career advancement opportunities for an Insert Molding Operator?

With experience and additional training, Insert Molding Operators can advance to roles such as Molding Supervisor, Production Manager, or Quality Control Manager.

What are the safety precautions that must be taken when working as an Insert Molding Operator?

Insert Molding Operators must follow strict safety protocols, including wearing appropriate protective gear, operating machines safely, and following established lockout/tagout procedures.

What is the average salary range for an Insert Molding Operator?

The average salary range for an Insert Molding Operator varies depending on factors such as experience, location, and company size, but typically falls between $18,000 and $30,000 per year.