Are you a seasoned Insert Operator seeking a new career path? Discover our professionally built Insert Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

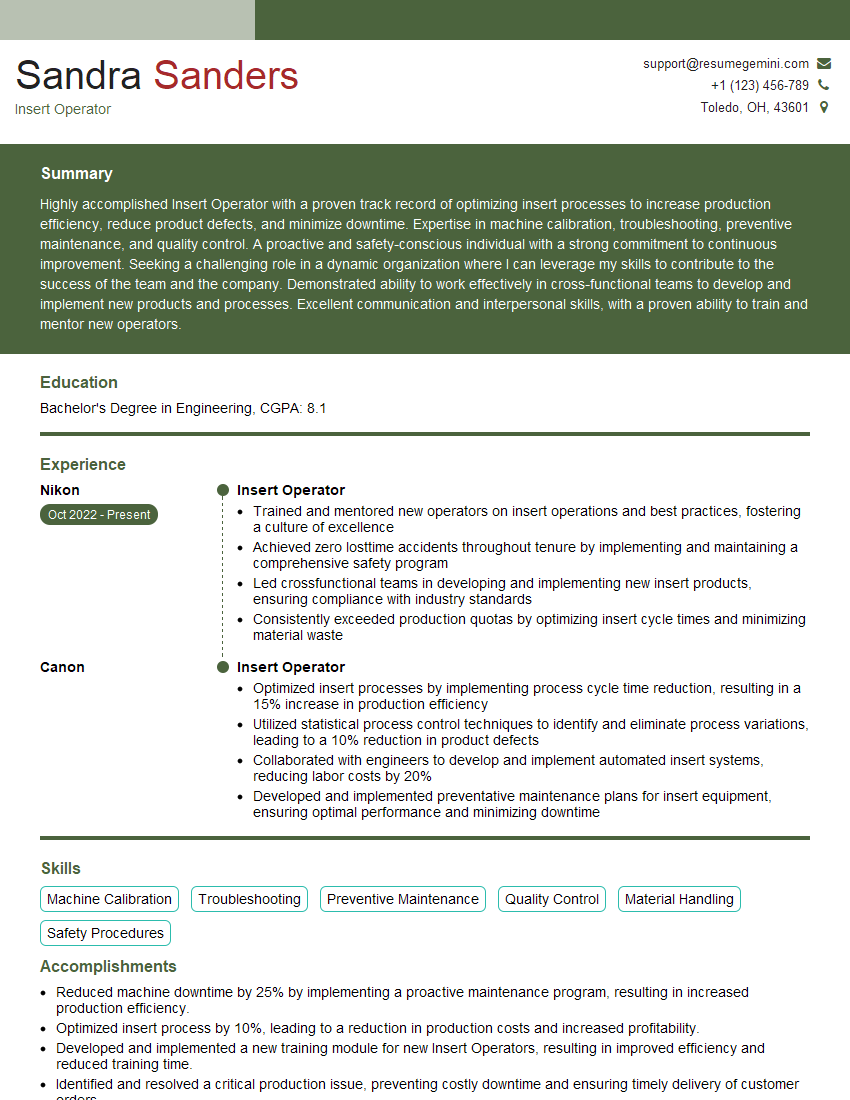

Sandra Sanders

Insert Operator

Summary

Highly accomplished Insert Operator with a proven track record of optimizing insert processes to increase production efficiency, reduce product defects, and minimize downtime. Expertise in machine calibration, troubleshooting, preventive maintenance, and quality control. A proactive and safety-conscious individual with a strong commitment to continuous improvement. Seeking a challenging role in a dynamic organization where I can leverage my skills to contribute to the success of the team and the company. Demonstrated ability to work effectively in cross-functional teams to develop and implement new products and processes. Excellent communication and interpersonal skills, with a proven ability to train and mentor new operators.

Education

Bachelor’s Degree in Engineering

September 2018

Skills

- Machine Calibration

- Troubleshooting

- Preventive Maintenance

- Quality Control

- Material Handling

- Safety Procedures

Work Experience

Insert Operator

- Trained and mentored new operators on insert operations and best practices, fostering a culture of excellence

- Achieved zero losttime accidents throughout tenure by implementing and maintaining a comprehensive safety program

- Led crossfunctional teams in developing and implementing new insert products, ensuring compliance with industry standards

- Consistently exceeded production quotas by optimizing insert cycle times and minimizing material waste

Insert Operator

- Optimized insert processes by implementing process cycle time reduction, resulting in a 15% increase in production efficiency

- Utilized statistical process control techniques to identify and eliminate process variations, leading to a 10% reduction in product defects

- Collaborated with engineers to develop and implement automated insert systems, reducing labor costs by 20%

- Developed and implemented preventative maintenance plans for insert equipment, ensuring optimal performance and minimizing downtime

Accomplishments

- Reduced machine downtime by 25% by implementing a proactive maintenance program, resulting in increased production efficiency.

- Optimized insert process by 10%, leading to a reduction in production costs and increased profitability.

- Developed and implemented a new training module for new Insert Operators, resulting in improved efficiency and reduced training time.

- Identified and resolved a critical production issue, preventing costly downtime and ensuring timely delivery of customer orders.

- Trained and mentored a team of junior Insert Operators, fostering their growth and improving overall team performance.

Awards

- Received the Best Insert Operator of the Year award for consistently surpassing performance targets.

- Recognized for exceptional safety record and contribution to a companywide safety initiative.

- Received Employee of the Month award for consistently exceeding expectations and demonstrating a positive attitude.

- Recognized for outstanding performance in a crossfunctional project that resulted in a successful product launch.

Certificates

- Certified Manufacturing Technologist (CMfgT)

- Certified Lean Six Sigma Green Belt

- Certified Maintenance and Reliability Technician (CMRT)

- Certified Robotics Technician

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Insert Operator

Highlight your technical skills.

Insert operators need to have a strong understanding of machine calibration, troubleshooting, preventive maintenance, and quality control. Make sure to list these skills prominently on your resume.Quantify your accomplishments.

When describing your accomplishments, use specific numbers and metrics to show the impact of your work. For example, you could say that you “reduced production time by 15%” or “improved product quality by 10%.”Demonstrate your commitment to safety.

Safety is a top priority for insert operators. Make sure to highlight your safety record on your resume and explain the steps you have taken to ensure a safe working environment.Be prepared to talk about your experience with different types of insert machines.

Insert operators need to be able to work with a variety of insert machines. Be prepared to discuss your experience with different types of machines in your interview.

Essential Experience Highlights for a Strong Insert Operator Resume

- Optimized insert processes by implementing process cycle time reduction, resulting in a 15% increase in production efficiency

- Utilized statistical process control techniques to identify and eliminate process variations, leading to a 10% reduction in product defects

- Collaborated with engineers to develop and implement automated insert systems, reducing labor costs by 20%

- Developed and implemented preventative maintenance plans for insert equipment, ensuring optimal performance and minimizing downtime

- Trained and mentored new operators on insert operations and best practices, fostering a culture of excellence

- Achieved zero lost-time accidents throughout tenure by implementing and maintaining a comprehensive safety program

- Led cross-functional teams in developing and implementing new insert products, ensuring compliance with industry standards

Frequently Asked Questions (FAQ’s) For Insert Operator

What are the most important skills for an Insert Operator?

The most important skills for an Insert Operator include machine calibration, troubleshooting, preventive maintenance, and quality control.

What is the average salary for an Insert Operator?

The average salary for an Insert Operator in the United States is $25 per hour.

What is the job outlook for Insert Operators?

The job outlook for Insert Operators is expected to grow by 5% over the next ten years.

What are the different types of insert machines?

The different types of insert machines include manual insert machines, semi-automatic insert machines, and fully automatic insert machines.

What are the safety precautions that Insert Operators need to take?

Insert Operators need to take a number of safety precautions, including wearing proper safety gear, following lockout/tagout procedures, and being aware of the potential hazards of the equipment they are using.

What are the career opportunities for Insert Operators?

Insert Operators can advance to positions such as Shift Supervisor, Production Manager, and Quality Control Manager.

What are the educational requirements for Insert Operators?

Insert Operators typically need a high school diploma or equivalent. Some employers may prefer candidates with a post-secondary degree in a related field, such as engineering or manufacturing.

What are the physical demands of being an Insert Operator?

Insert Operators need to be able to stand for long periods of time, lift heavy objects, and work in a fast-paced environment.