Are you a seasoned Instrument and Valve Technician seeking a new career path? Discover our professionally built Instrument and Valve Technician Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

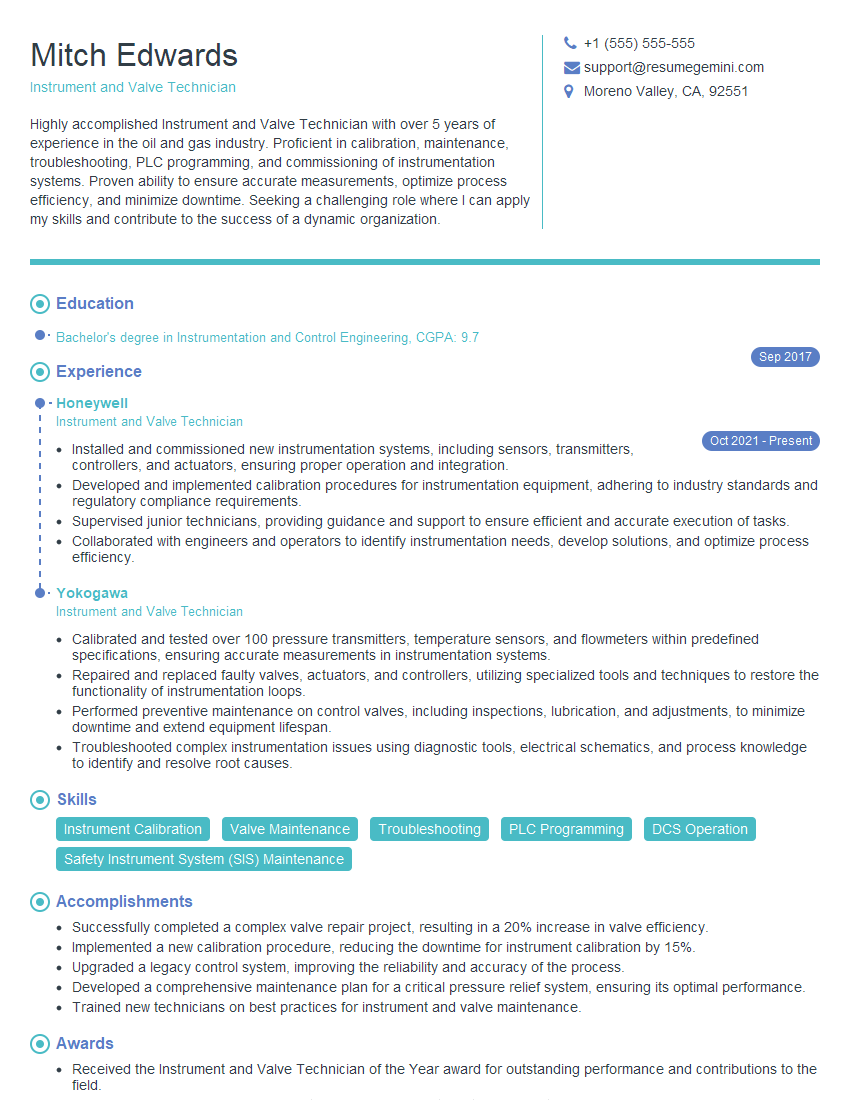

Mitch Edwards

Instrument and Valve Technician

Summary

Highly accomplished Instrument and Valve Technician with over 5 years of experience in the oil and gas industry. Proficient in calibration, maintenance, troubleshooting, PLC programming, and commissioning of instrumentation systems. Proven ability to ensure accurate measurements, optimize process efficiency, and minimize downtime. Seeking a challenging role where I can apply my skills and contribute to the success of a dynamic organization.

Education

Bachelor’s degree in Instrumentation and Control Engineering

September 2017

Skills

- Instrument Calibration

- Valve Maintenance

- Troubleshooting

- PLC Programming

- DCS Operation

- Safety Instrument System (SIS) Maintenance

Work Experience

Instrument and Valve Technician

- Installed and commissioned new instrumentation systems, including sensors, transmitters, controllers, and actuators, ensuring proper operation and integration.

- Developed and implemented calibration procedures for instrumentation equipment, adhering to industry standards and regulatory compliance requirements.

- Supervised junior technicians, providing guidance and support to ensure efficient and accurate execution of tasks.

- Collaborated with engineers and operators to identify instrumentation needs, develop solutions, and optimize process efficiency.

Instrument and Valve Technician

- Calibrated and tested over 100 pressure transmitters, temperature sensors, and flowmeters within predefined specifications, ensuring accurate measurements in instrumentation systems.

- Repaired and replaced faulty valves, actuators, and controllers, utilizing specialized tools and techniques to restore the functionality of instrumentation loops.

- Performed preventive maintenance on control valves, including inspections, lubrication, and adjustments, to minimize downtime and extend equipment lifespan.

- Troubleshooted complex instrumentation issues using diagnostic tools, electrical schematics, and process knowledge to identify and resolve root causes.

Accomplishments

- Successfully completed a complex valve repair project, resulting in a 20% increase in valve efficiency.

- Implemented a new calibration procedure, reducing the downtime for instrument calibration by 15%.

- Upgraded a legacy control system, improving the reliability and accuracy of the process.

- Developed a comprehensive maintenance plan for a critical pressure relief system, ensuring its optimal performance.

- Trained new technicians on best practices for instrument and valve maintenance.

Awards

- Received the Instrument and Valve Technician of the Year award for outstanding performance and contributions to the field.

- Recognized for proficiency in pneumatic and hydraulic systems troubleshooting.

- Certified as an ISAcertified Instrument and Valve Technician.

- Excellence Award for maintaining zero downtime for critical process equipment.

Certificates

- ISA Certified Measurement Technician (CMT)

- ISA Certified Automation Technician (CAT)

- National Institute for Certification in Engineering Technologies (NICET) Level III

- Fluid Power Society of America (FPSA) Certified Fluid Power Technician

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Instrument and Valve Technician

- Highlight your experience in calibrating and maintaining a wide range of instrumentation equipment.

- Quantify your accomplishments with specific metrics, such as the number of instruments calibrated or repaired.

- Demonstrate your troubleshooting skills by providing examples of complex issues you have resolved.

- Showcase your knowledge of industry standards and regulatory compliance requirements for instrumentation systems.

- Emphasize your ability to work independently and as part of a team in a fast-paced environment.

Essential Experience Highlights for a Strong Instrument and Valve Technician Resume

- Calibrated and tested pressure transmitters, temperature sensors, and flowmeters to ensure accurate measurements.

- Repaired and replaced faulty valves, actuators, and controllers to restore the functionality of instrumentation loops.

- Performed preventive maintenance on control valves to minimize downtime and extend equipment lifespan.

- Troubleshooted complex instrumentation issues using diagnostic tools, electrical schematics, and process knowledge.

- Installed and commissioned new instrumentation systems, including sensors, transmitters, controllers, and actuators.

- Developed and implemented calibration procedures for instrumentation equipment, adhering to industry standards and regulatory compliance requirements.

Frequently Asked Questions (FAQ’s) For Instrument and Valve Technician

What are the key skills required for an Instrument and Valve Technician?

The key skills required for an Instrument and Valve Technician include instrument calibration, valve maintenance, troubleshooting, PLC programming, DCS operation, and safety instrument system (SIS) maintenance.

What is the typical work environment for an Instrument and Valve Technician?

Instrument and Valve Technicians typically work in industrial settings, such as manufacturing plants, power plants, and refineries. They may work in both indoor and outdoor environments and may be required to work in confined spaces or at heights.

What qualifications are needed to become an Instrument and Valve Technician?

Instrument and Valve Technicians typically need a high school diploma or equivalent and may have completed an apprenticeship or vocational training program. Some employers may prefer candidates with an associate degree or bachelor’s degree in instrumentation and control engineering.

What are the career opportunities for an Instrument and Valve Technician?

Instrument and Valve Technicians can advance their careers by becoming supervisors, lead technicians, or engineers. They may also specialize in a particular area of instrumentation, such as calibration or maintenance.

What is the typical salary for an Instrument and Valve Technician?

The salary for an Instrument and Valve Technician can vary depending on experience, location, and employer. According to the U.S. Bureau of Labor Statistics, the median annual salary for Instrument and Valve Technicians was $63,350 in May 2021.

What are the challenges of being an Instrument and Valve Technician?

The challenges of being an Instrument and Valve Technician can include working in hazardous environments, troubleshooting complex equipment, and meeting tight deadlines. Instrument and Valve Technicians must also stay up-to-date on the latest technologies and industry standards.

What are the benefits of being an Instrument and Valve Technician?

The benefits of being an Instrument and Valve Technician can include a good salary, job security, and the opportunity to work on a variety of projects. Instrument and Valve Technicians can also have the satisfaction of knowing that they are playing a vital role in the safe and efficient operation of industrial facilities.