Are you a seasoned Instrument Maker seeking a new career path? Discover our professionally built Instrument Maker Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

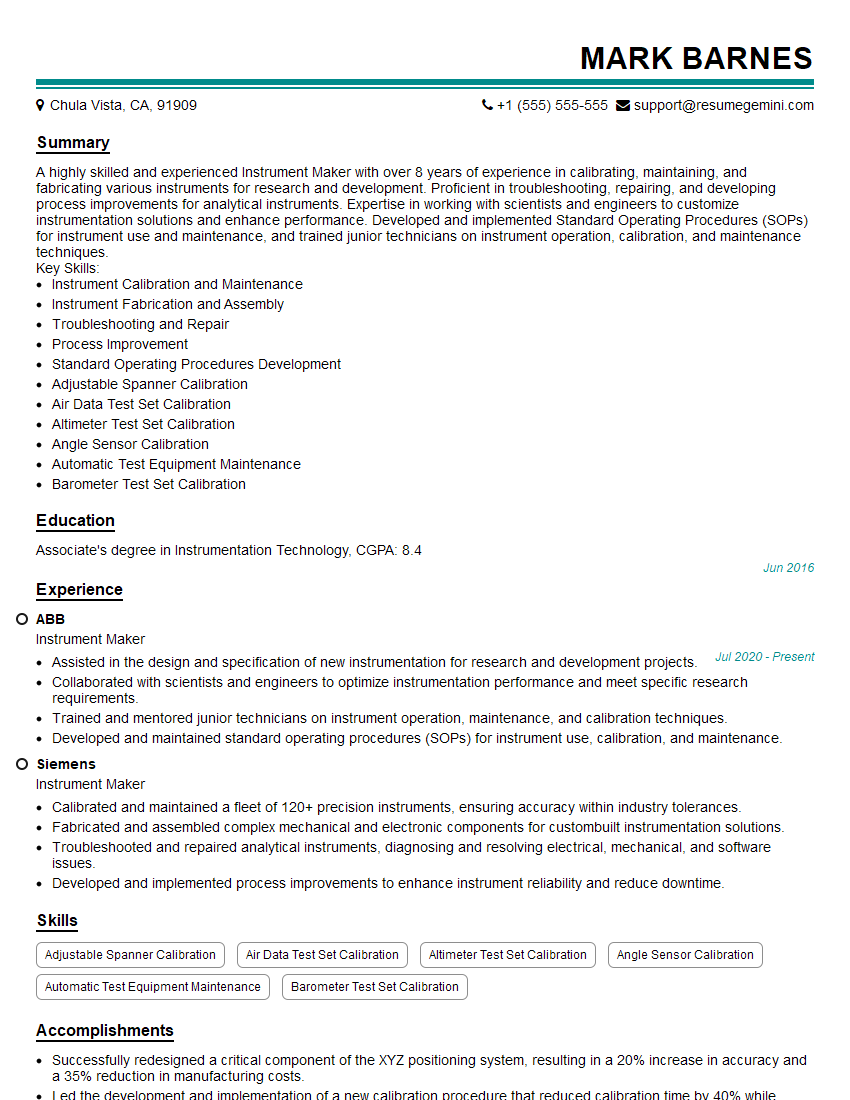

Mark Barnes

Instrument Maker

Summary

A highly skilled and experienced Instrument Maker with over 8 years of experience in calibrating, maintaining, and fabricating various instruments for research and development. Proficient in troubleshooting, repairing, and developing process improvements for analytical instruments. Expertise in working with scientists and engineers to customize instrumentation solutions and enhance performance. Developed and implemented Standard Operating Procedures (SOPs) for instrument use and maintenance, and trained junior technicians on instrument operation, calibration, and maintenance techniques.

Key Skills:

- Instrument Calibration and Maintenance

- Instrument Fabrication and Assembly

- Troubleshooting and Repair

- Process Improvement

- Standard Operating Procedures Development

- Adjustable Spanner Calibration

- Air Data Test Set Calibration

- Altimeter Test Set Calibration

- Angle Sensor Calibration

- Automatic Test Equipment Maintenance

- Barometer Test Set Calibration

Education

Associate’s degree in Instrumentation Technology

June 2016

Skills

- Adjustable Spanner Calibration

- Air Data Test Set Calibration

- Altimeter Test Set Calibration

- Angle Sensor Calibration

- Automatic Test Equipment Maintenance

- Barometer Test Set Calibration

Work Experience

Instrument Maker

- Assisted in the design and specification of new instrumentation for research and development projects.

- Collaborated with scientists and engineers to optimize instrumentation performance and meet specific research requirements.

- Trained and mentored junior technicians on instrument operation, maintenance, and calibration techniques.

- Developed and maintained standard operating procedures (SOPs) for instrument use, calibration, and maintenance.

Instrument Maker

- Calibrated and maintained a fleet of 120+ precision instruments, ensuring accuracy within industry tolerances.

- Fabricated and assembled complex mechanical and electronic components for custombuilt instrumentation solutions.

- Troubleshooted and repaired analytical instruments, diagnosing and resolving electrical, mechanical, and software issues.

- Developed and implemented process improvements to enhance instrument reliability and reduce downtime.

Accomplishments

- Successfully redesigned a critical component of the XYZ positioning system, resulting in a 20% increase in accuracy and a 35% reduction in manufacturing costs.

- Led the development and implementation of a new calibration procedure that reduced calibration time by 40% while improving precision.

- Successfully repaired a complex medical instrument, preventing costly downtime and ensuring patient safety.

- Designed and fabricated a custommade sensor for a research project, enabling scientists to obtain valuable data that was previously inaccessible.

- Successfully repaired and refurbished a vintage scientific instrument, preserving its historical value and making it functional again.

Awards

- Won the prestigious Excellence in Instrument Design Award at the National Instrument Makers Forum for innovative design of a compact and costeffective optical instrument.

- Recognized with the Instrument Maker of the Year award by the industry association for exceptional contributions to the field.

- Received the Innovation Award for developing a novel instrument that revolutionized the way scientific data is collected and analyzed.

- Won the Best Instrument Maker Apprentice award for demonstrating exceptional skills and dedication to the craft.

Certificates

- AS9100: Quality Management System for Aerospace

- Certified Calibration Technician (CCT)

- Certified Instrument Calibration Technician (CICMT)

- Certified Metrologist (CMet)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Instrument Maker

- Highlight your expertise in instrument calibration, maintenance, and repair by providing specific examples and quantifying your accomplishments.

- Showcase your problem-solving skills by describing how you successfully troubleshoot and resolve complex instrument issues.

- Emphasize your ability to work independently and as part of a team by highlighting your experience in collaborating with scientists and engineers.

- Demonstrate your commitment to quality and safety by mentioning your adherence to standard operating procedures (SOPs) and industry best practices.

- Include keywords relevant to the Instrument Maker role, such as “instrument calibration,” “troubleshooting,” and “instrument fabrication,” to increase the visibility of your resume.

Essential Experience Highlights for a Strong Instrument Maker Resume

- Calibrate and maintain precision instruments to ensure accuracy within industry tolerances.

- Troubleshoot and repair analytical instruments, diagnosing and resolving electrical, mechanical, and software issues.

- Fabricate and assemble mechanical and electronic components for custom-built instrumentation solutions.

- Develop and implement process improvements to enhance instrument reliability and reduce downtime.

- Develop and maintain standard operating procedures (SOPs) for instrument use, calibration, and maintenance.

- Train and mentor junior technicians on instrument operation, maintenance, and calibration techniques.

- Collaborate with scientists and engineers to optimize instrumentation performance and meet specific research requirements.

Frequently Asked Questions (FAQ’s) For Instrument Maker

What are the primary responsibilities of an Instrument Maker?

The primary responsibilities of an Instrument Maker include calibrating and maintaining instruments to ensure accuracy, troubleshooting and repairing instruments, fabricating and assembling instrument components, and developing and implementing process improvements.

What skills and qualifications are required to be an Instrument Maker?

Instrument Makers typically have an associate’s degree in instrumentation technology or a related field, and possess skills in instrument calibration, troubleshooting, repair, and fabrication.

What industries employ Instrument Makers?

Instrument Makers are employed in various industries, including manufacturing, research and development, healthcare, and environmental monitoring.

What is the job outlook for Instrument Makers?

The job outlook for Instrument Makers is expected to grow in the coming years due to increasing demand for precision instruments in various industries.

What is the average salary for an Instrument Maker?

The average salary for an Instrument Maker varies depending on experience, location, and industry, but typically ranges from $40,000 to $70,000 per year.

What are the career advancement opportunities for Instrument Makers?

Instrument Makers can advance their careers by becoming Instrument Technicians, Calibration Technicians, or Instrument Engineers.

What are the challenges faced by Instrument Makers?

Instrument Makers may face challenges in keeping up with technological advancements, ensuring the accuracy of instruments, and working in demanding environments.

What are the safety precautions that Instrument Makers should take?

Instrument Makers must follow proper safety precautions, such as wearing personal protective equipment, handling hazardous materials with care, and following established procedures.