Are you a seasoned Instrument Repair Technician seeking a new career path? Discover our professionally built Instrument Repair Technician Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

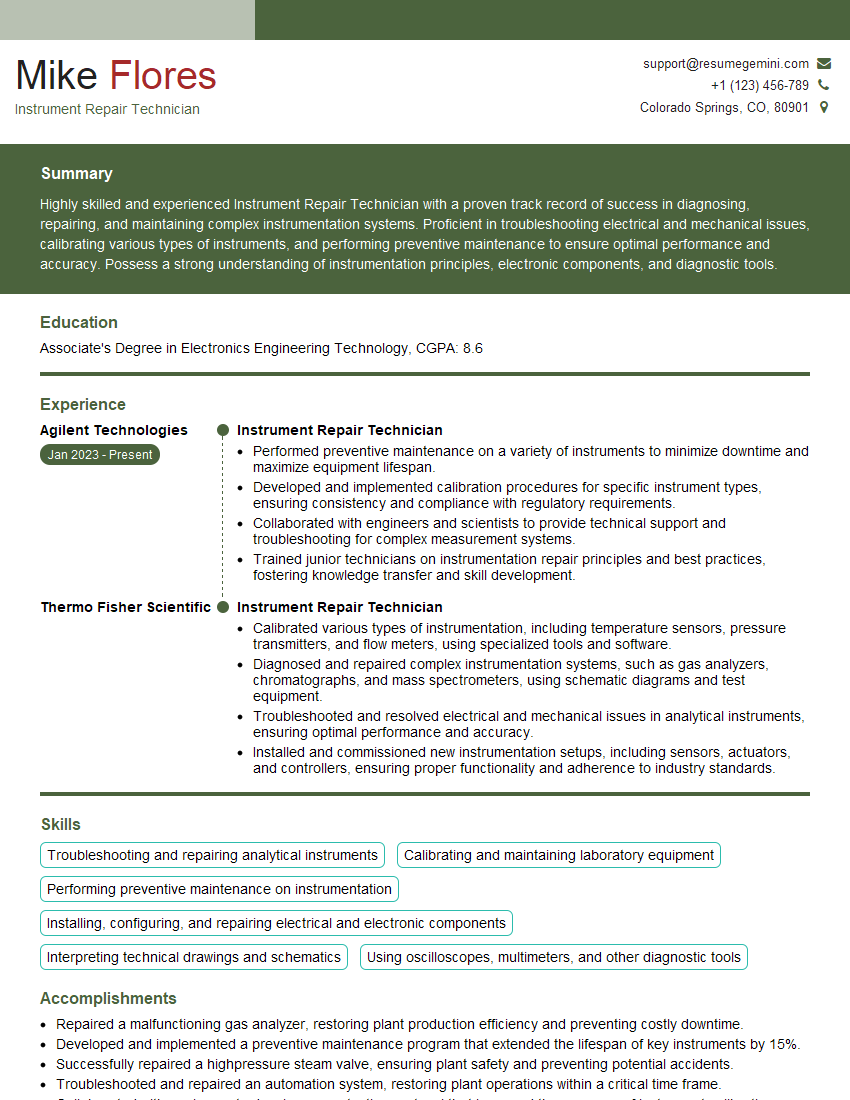

Mike Flores

Instrument Repair Technician

Summary

Highly skilled and experienced Instrument Repair Technician with a proven track record of success in diagnosing, repairing, and maintaining complex instrumentation systems. Proficient in troubleshooting electrical and mechanical issues, calibrating various types of instruments, and performing preventive maintenance to ensure optimal performance and accuracy. Possess a strong understanding of instrumentation principles, electronic components, and diagnostic tools.

Education

Associate’s Degree in Electronics Engineering Technology

December 2018

Skills

- Troubleshooting and repairing analytical instruments

- Calibrating and maintaining laboratory equipment

- Performing preventive maintenance on instrumentation

- Installing, configuring, and repairing electrical and electronic components

- Interpreting technical drawings and schematics

- Using oscilloscopes, multimeters, and other diagnostic tools

Work Experience

Instrument Repair Technician

- Performed preventive maintenance on a variety of instruments to minimize downtime and maximize equipment lifespan.

- Developed and implemented calibration procedures for specific instrument types, ensuring consistency and compliance with regulatory requirements.

- Collaborated with engineers and scientists to provide technical support and troubleshooting for complex measurement systems.

- Trained junior technicians on instrumentation repair principles and best practices, fostering knowledge transfer and skill development.

Instrument Repair Technician

- Calibrated various types of instrumentation, including temperature sensors, pressure transmitters, and flow meters, using specialized tools and software.

- Diagnosed and repaired complex instrumentation systems, such as gas analyzers, chromatographs, and mass spectrometers, using schematic diagrams and test equipment.

- Troubleshooted and resolved electrical and mechanical issues in analytical instruments, ensuring optimal performance and accuracy.

- Installed and commissioned new instrumentation setups, including sensors, actuators, and controllers, ensuring proper functionality and adherence to industry standards.

Accomplishments

- Repaired a malfunctioning gas analyzer, restoring plant production efficiency and preventing costly downtime.

- Developed and implemented a preventive maintenance program that extended the lifespan of key instruments by 15%.

- Successfully repaired a highpressure steam valve, ensuring plant safety and preventing potential accidents.

- Troubleshooted and repaired an automation system, restoring plant operations within a critical time frame.

- Collaborated with engineers to develop a new testing protocol that improved the accuracy of instrument calibration.

Awards

- Recognized for exceptional performance in diagnosing and repairing complex instrumentation systems.

- Received award for innovative repair technique that reduced repair time by 20%.

- Honored with employee of the month award for consistently exceeding performance expectations in repairing critical instruments.

- Awarded for significant contribution to the teams success in repairing and maintaining highly specialized analytical instrumentation.

Certificates

- Certified Medical Equipment Repair Technician (CMERT)

- Certified Electronic Technician (CET)

- Certified Maintenance and Reliability Technician (CMRT)

- Certified Fluid Power Technician (CFPT)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Instrument Repair Technician

- Highlight your technical skills and experience in troubleshooting and repairing analytical instruments.

- Quantify your accomplishments and provide specific examples of your work.

- Showcase your knowledge of industry regulations and standards.

- Emphasize your ability to work independently and as part of a team.

Essential Experience Highlights for a Strong Instrument Repair Technician Resume

- Diagnosed and repaired complex instrumentation systems, including gas analyzers, chromatographs, and mass spectrometers, using schematic diagrams and test equipment.

- Installed and commissioned new instrumentation setups, including sensors, actuators, and controllers, ensuring proper functionality and adherence to industry standards.

- Performed preventive maintenance on a variety of instruments to minimize downtime and maximize equipment lifespan.

- Developed and implemented calibration procedures for specific instrument types, ensuring consistency and compliance with regulatory requirements.

- Collaborated with engineers and scientists to provide technical support and troubleshooting for complex measurement systems.

- Trained junior technicians on instrumentation repair principles and best practices, fostering knowledge transfer and skill development.

Frequently Asked Questions (FAQ’s) For Instrument Repair Technician

What are the key skills required for an Instrument Repair Technician?

Key skills include troubleshooting and repairing analytical instruments, calibrating and maintaining laboratory equipment, performing preventive maintenance on instrumentation, installing, configuring, and repairing electrical and electronic components, interpreting technical drawings and schematics, and using oscilloscopes, multimeters, and other diagnostic tools.

What are the career prospects for an Instrument Repair Technician?

Instrument Repair Technicians are in high demand in various industries, including pharmaceutical, biotechnology, food and beverage, and manufacturing. With experience, technicians can advance to roles such as Instrumentation Engineer, Quality Assurance Manager, or Technical Support Specialist.

What is the typical work environment for an Instrument Repair Technician?

Instrument Repair Technicians typically work in laboratory or manufacturing settings. They may work independently or as part of a team, and may be required to work overtime or on-call.

What are the salary expectations for an Instrument Repair Technician?

Salary expectations vary depending on experience, location, and industry. According to the U.S. Bureau of Labor Statistics, the median annual salary for Instrument Repair Technicians is around $56,000.

What are the educational requirements for an Instrument Repair Technician?

Most employers prefer candidates with an Associate’s Degree in Electronics Engineering Technology or a related field. Some employers may also consider candidates with relevant work experience and certifications.

What are the professional development opportunities for an Instrument Repair Technician?

Instrument Repair Technicians can enhance their skills and knowledge through certifications, workshops, and training programs offered by professional organizations such as the International Society of Automation (ISA) and the American Society for Nondestructive Testing (ASNT).