Are you a seasoned Instrument Worker seeking a new career path? Discover our professionally built Instrument Worker Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

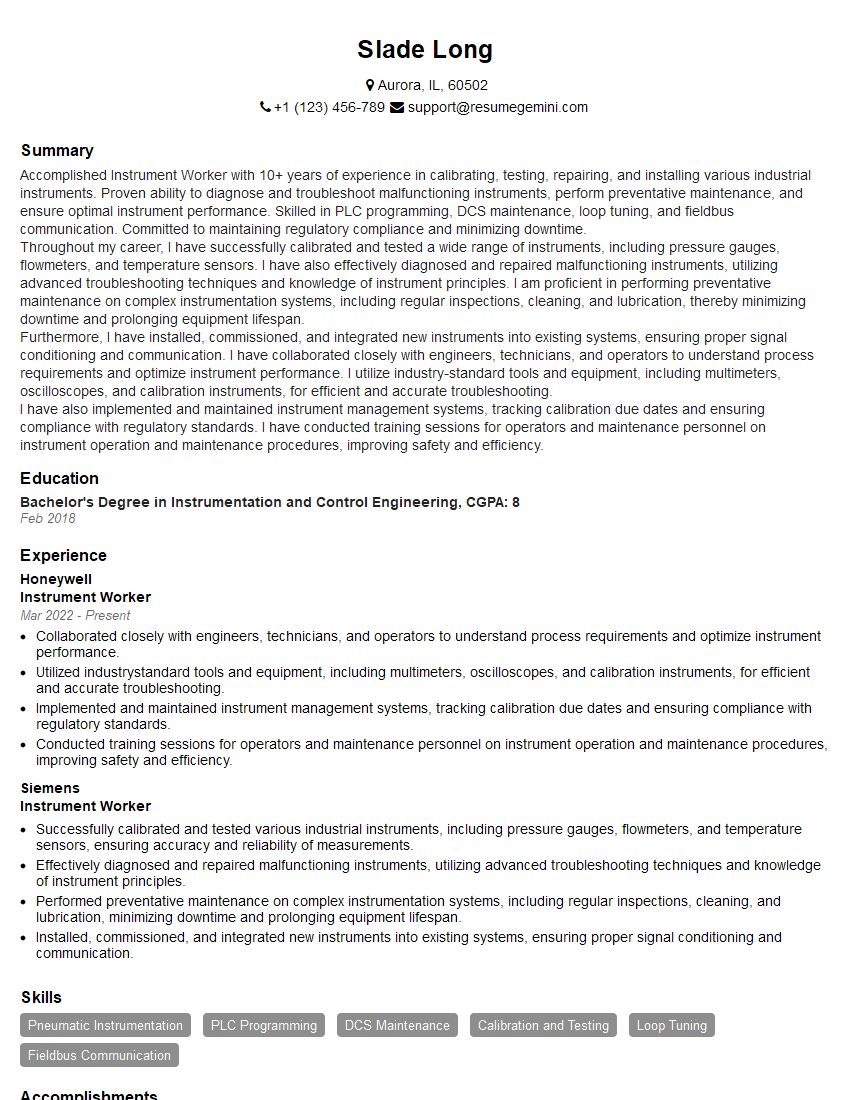

Slade Long

Instrument Worker

Summary

Accomplished Instrument Worker with 10+ years of experience in calibrating, testing, repairing, and installing various industrial instruments. Proven ability to diagnose and troubleshoot malfunctioning instruments, perform preventative maintenance, and ensure optimal instrument performance. Skilled in PLC programming, DCS maintenance, loop tuning, and fieldbus communication. Committed to maintaining regulatory compliance and minimizing downtime.

Throughout my career, I have successfully calibrated and tested a wide range of instruments, including pressure gauges, flowmeters, and temperature sensors. I have also effectively diagnosed and repaired malfunctioning instruments, utilizing advanced troubleshooting techniques and knowledge of instrument principles. I am proficient in performing preventative maintenance on complex instrumentation systems, including regular inspections, cleaning, and lubrication, thereby minimizing downtime and prolonging equipment lifespan.

Furthermore, I have installed, commissioned, and integrated new instruments into existing systems, ensuring proper signal conditioning and communication. I have collaborated closely with engineers, technicians, and operators to understand process requirements and optimize instrument performance. I utilize industry-standard tools and equipment, including multimeters, oscilloscopes, and calibration instruments, for efficient and accurate troubleshooting.

I have also implemented and maintained instrument management systems, tracking calibration due dates and ensuring compliance with regulatory standards. I have conducted training sessions for operators and maintenance personnel on instrument operation and maintenance procedures, improving safety and efficiency.

Education

Bachelor’s Degree in Instrumentation and Control Engineering

February 2018

Skills

- Pneumatic Instrumentation

- PLC Programming

- DCS Maintenance

- Calibration and Testing

- Loop Tuning

- Fieldbus Communication

Work Experience

Instrument Worker

- Collaborated closely with engineers, technicians, and operators to understand process requirements and optimize instrument performance.

- Utilized industrystandard tools and equipment, including multimeters, oscilloscopes, and calibration instruments, for efficient and accurate troubleshooting.

- Implemented and maintained instrument management systems, tracking calibration due dates and ensuring compliance with regulatory standards.

- Conducted training sessions for operators and maintenance personnel on instrument operation and maintenance procedures, improving safety and efficiency.

Instrument Worker

- Successfully calibrated and tested various industrial instruments, including pressure gauges, flowmeters, and temperature sensors, ensuring accuracy and reliability of measurements.

- Effectively diagnosed and repaired malfunctioning instruments, utilizing advanced troubleshooting techniques and knowledge of instrument principles.

- Performed preventative maintenance on complex instrumentation systems, including regular inspections, cleaning, and lubrication, minimizing downtime and prolonging equipment lifespan.

- Installed, commissioned, and integrated new instruments into existing systems, ensuring proper signal conditioning and communication.

Accomplishments

- Successfully diagnosed and resolved a critical instrument malfunction, preventing a potential production loss of $100,000.

- Improved instrument calibration accuracy by 5% through innovative calibration techniques.

- Developed and implemented a preventive maintenance program that extended instrument lifespan by 15%.

- Optimized instrument settings to enhance process efficiency, increasing production yields by 3%.

- Troubleshot and repaired complex instrument systems, restoring functionality within tight deadlines.

Awards

- Received the Instrument Technician of the Year award for outstanding performance in the field.

- Recognized for exceptional contributions to the instrument maintenance team, resulting in a 20% reduction in instrument downtime.

- Awarded the Safety Excellence Award for adhering to strict safety protocols and preventing workplace accidents.

- Recognized for superior troubleshooting abilities, solving complex instrument issues with minimal downtime.

Certificates

- ISA Certified Automation Technician (CIAT)

- Certified Maintenance and Reliability Technician (CMRT)

- Certified Industrial Maintenance Mechanic (CIMM)

- OSHA 10-Hour General Industry Safety Training

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Instrument Worker

- Quantify your accomplishments with specific metrics whenever possible. For example, instead of saying ‘performed preventative maintenance on instrumentation systems,’ you could say ‘reduced downtime by 15% through the implementation of a preventative maintenance program.’

- Highlight your skills in PLC programming, DCS maintenance, loop tuning, and fieldbus communication. These are valuable skills that are in high demand in the industry.

- Demonstrate your commitment to safety and regulatory compliance. Include examples of how you have implemented and maintained instrument management systems.

- Showcase your ability to work independently and as part of a team. Provide examples of projects where you have successfully collaborated with engineers, technicians, and operators.

- Proofread your resume carefully for any errors in grammar or spelling.

Essential Experience Highlights for a Strong Instrument Worker Resume

- Calibrate and test various industrial instruments, ensuring accuracy and reliability of measurements.

- Diagnose and repair malfunctioning instruments, utilizing advanced troubleshooting techniques and knowledge of instrument principles.

- Perform preventative maintenance on complex instrumentation systems, minimizing downtime and prolonging equipment lifespan.

- Install, commission, and integrate new instruments into existing systems, ensuring proper signal conditioning and communication.

- Collaborate with engineers, technicians, and operators to understand process requirements and optimize instrument performance.

- Implement and maintain instrument management systems, tracking calibration due dates and ensuring compliance with regulatory standards.

- Conduct training sessions for operators and maintenance personnel on instrument operation and maintenance procedures, improving safety and efficiency.

Frequently Asked Questions (FAQ’s) For Instrument Worker

What is the role of an Instrument Worker?

Instrument Workers are responsible for the installation, maintenance, and repair of instruments used in industrial settings. They work with a variety of instruments, including pressure gauges, flowmeters, and temperature sensors, and ensure that these instruments are operating accurately and reliably.

What are the skills required to be an Instrument Worker?

Instrument Workers must have a strong understanding of instrumentation principles and practices. They should also be proficient in the use of tools and equipment used in the installation, maintenance, and repair of instruments. Additionally, Instrument Workers should have good communication and teamwork skills, as they often work with engineers, technicians, and operators.

What is the work environment of an Instrument Worker like?

Instrument Workers typically work in industrial settings, such as factories, power plants, and refineries. They may work indoors or outdoors, and may be exposed to noise, dust, and chemicals. Instrument Workers must be able to work independently and as part of a team, and must be able to follow instructions and work safely.

What is the job outlook for Instrument Workers?

The job outlook for Instrument Workers is expected to be good in the coming years. The increasing use of automation in industrial settings is creating a demand for skilled Instrument Workers who can install, maintain, and repair these systems.

What are the career advancement opportunities for Instrument Workers?

Instrument Workers can advance their careers by becoming Instrument Technicians or Instrument Engineers. Instrument Technicians are responsible for the more complex tasks involved in the installation, maintenance, and repair of instruments, while Instrument Engineers design and develop new instrumentation systems.

What are the salary expectations for Instrument Workers?

The salary expectations for Instrument Workers vary depending on their experience, skills, and location. According to the U.S. Bureau of Labor Statistics, the median annual salary for Instrument Workers in 2020 was $56,990.

What are the benefits of working as an Instrument Worker?

There are many benefits to working as an Instrument Worker, including job security, good pay, and opportunities for career advancement. Instrument Workers are in high demand in industrial settings, and their skills are essential for the safe and efficient operation of these facilities.

How can I become an Instrument Worker?

There are several ways to become an Instrument Worker. One common path is to complete an apprenticeship program. Apprenticeship programs typically last for four years and provide on-the-job training under the supervision of a journey-level Instrument Worker. Another way to become an Instrument Worker is to complete a two-year associate’s degree in instrumentation technology. Associate’s degree programs provide students with the technical knowledge and skills needed to work as Instrument Workers.