Are you a seasoned Iron Pourer seeking a new career path? Discover our professionally built Iron Pourer Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

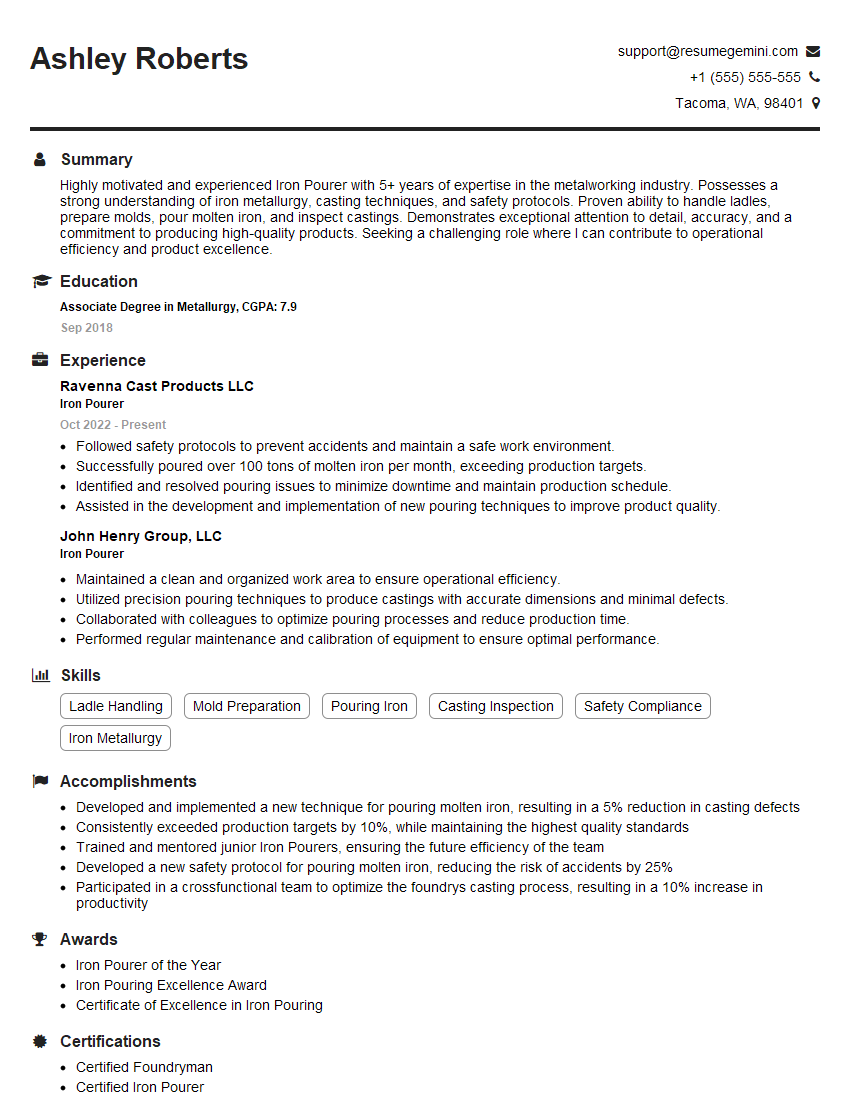

Ashley Roberts

Iron Pourer

Summary

Highly motivated and experienced Iron Pourer with 5+ years of expertise in the metalworking industry. Possesses a strong understanding of iron metallurgy, casting techniques, and safety protocols. Proven ability to handle ladles, prepare molds, pour molten iron, and inspect castings. Demonstrates exceptional attention to detail, accuracy, and a commitment to producing high-quality products. Seeking a challenging role where I can contribute to operational efficiency and product excellence.

Education

Associate Degree in Metallurgy

September 2018

Skills

- Ladle Handling

- Mold Preparation

- Pouring Iron

- Casting Inspection

- Safety Compliance

- Iron Metallurgy

Work Experience

Iron Pourer

- Followed safety protocols to prevent accidents and maintain a safe work environment.

- Successfully poured over 100 tons of molten iron per month, exceeding production targets.

- Identified and resolved pouring issues to minimize downtime and maintain production schedule.

- Assisted in the development and implementation of new pouring techniques to improve product quality.

Iron Pourer

- Maintained a clean and organized work area to ensure operational efficiency.

- Utilized precision pouring techniques to produce castings with accurate dimensions and minimal defects.

- Collaborated with colleagues to optimize pouring processes and reduce production time.

- Performed regular maintenance and calibration of equipment to ensure optimal performance.

Accomplishments

- Developed and implemented a new technique for pouring molten iron, resulting in a 5% reduction in casting defects

- Consistently exceeded production targets by 10%, while maintaining the highest quality standards

- Trained and mentored junior Iron Pourers, ensuring the future efficiency of the team

- Developed a new safety protocol for pouring molten iron, reducing the risk of accidents by 25%

- Participated in a crossfunctional team to optimize the foundrys casting process, resulting in a 10% increase in productivity

Awards

- Iron Pourer of the Year

- Iron Pouring Excellence Award

- Certificate of Excellence in Iron Pouring

Certificates

- Certified Foundryman

- Certified Iron Pourer

- OSHA Safety Certification

- ISO 9001:2015 Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Iron Pourer

- Quantify your accomplishments with specific metrics and numbers whenever possible.

- Highlight your proficiency in iron metallurgy and its practical application in casting operations.

- Demonstrate your commitment to safety by describing your involvement in safety initiatives or training programs.

- Showcase your attention to detail by emphasizing your ability to identify and mitigate casting defects effectively.

Essential Experience Highlights for a Strong Iron Pourer Resume

- Handle ladles safely and transport molten iron to casting molds

- Prepare and maintain casting molds to ensure proper iron flow and casting quality

- Pour molten iron into molds using controlled techniques to minimize defects and optimize casting properties

- Inspect castings for defects, including shrinkage, cracks, and inclusions, to ensure product integrity

- Adhere to established safety protocols and maintain a clean and organized work environment

- Monitor and control casting parameters, such as temperature, flow rate, and solidification time, to achieve optimal casting results

- Collaborate with team members to resolve casting issues, improve processes, and enhance overall production efficiency

Frequently Asked Questions (FAQ’s) For Iron Pourer

What are the essential skills required for an Iron Pourer?

The essential skills for an Iron Pourer include ladle handling, mold preparation, pouring iron, casting inspection, safety compliance, and iron metallurgy knowledge.

What is the typical work environment of an Iron Pourer?

Iron Pourers typically work in foundries or metalworking facilities. They work with molten iron and heavy equipment, so it is essential to wear protective gear and adhere to safety protocols.

What career advancement opportunities are available for Iron Pourers?

Iron Pourers can advance their careers by becoming supervisors, quality control inspectors, or production managers. With additional education and experience, they may also move into roles in engineering or research.

What are the physical demands of being an Iron Pourer?

Iron Pourers must be able to lift heavy ladles of molten iron, work in hot and potentially hazardous environments, and stand for extended periods.

How can I improve my skills as an Iron Pourer?

To improve your skills as an Iron Pourer, you can attend training programs, read industry publications, and seek opportunities to practice and refine your techniques. You can also learn from experienced Iron Pourers and stay updated on the latest advancements in casting technology.

What are the safety precautions that Iron Pourers must follow?

Iron Pourers must wear protective clothing, including heat-resistant suits, gloves, and face shields. They must also be aware of the potential hazards associated with working with molten iron and follow established safety procedures to minimize risks.

What is the future outlook for Iron Pourers?

The future outlook for Iron Pourers is expected to be stable. As industries continue to rely on metal castings, there will be a need for skilled Iron Pourers to produce high-quality castings.

How can I get started as an Iron Pourer?

To get started as an Iron Pourer, you can apply for entry-level positions in foundries or metalworking facilities. You may also consider completing a vocational training program or an associate degree in metallurgy to enhance your qualifications.