Are you a seasoned Jig Boring Machine Set-Up Operator seeking a new career path? Discover our professionally built Jig Boring Machine Set-Up Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

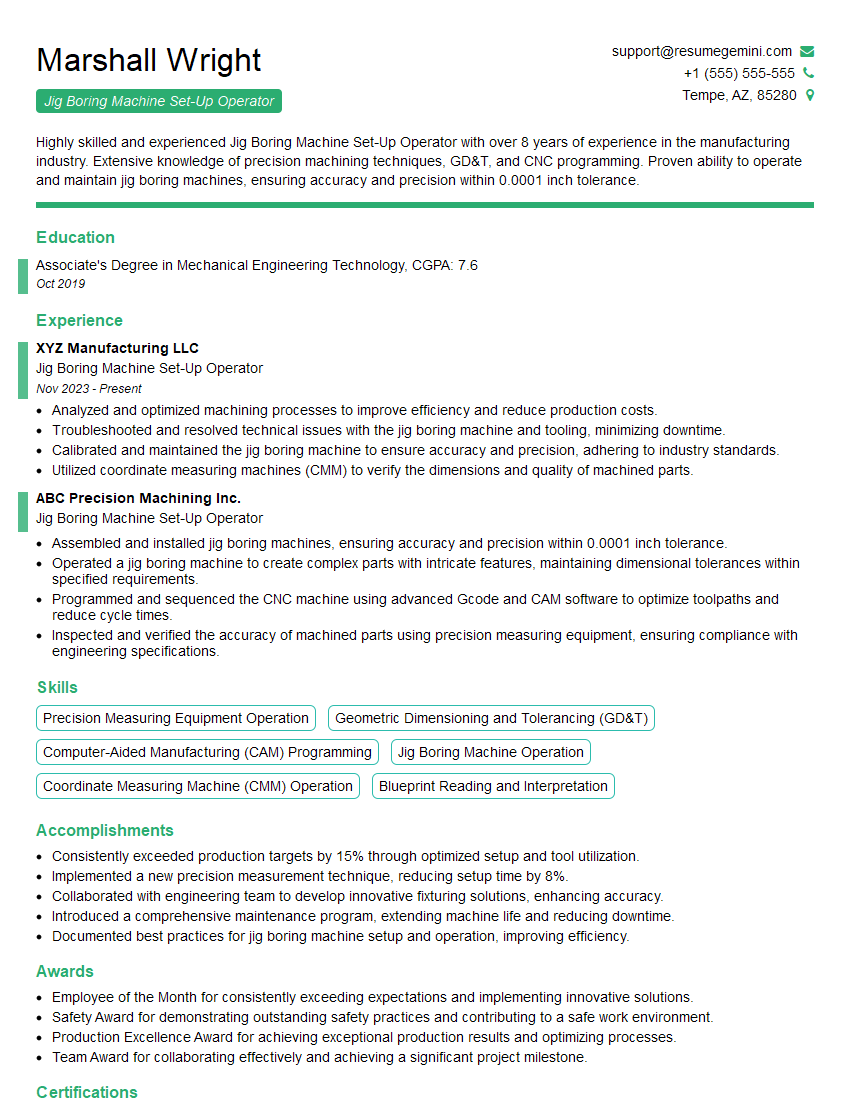

Marshall Wright

Jig Boring Machine Set-Up Operator

Summary

Highly skilled and experienced Jig Boring Machine Set-Up Operator with over 8 years of experience in the manufacturing industry. Extensive knowledge of precision machining techniques, GD&T, and CNC programming. Proven ability to operate and maintain jig boring machines, ensuring accuracy and precision within 0.0001 inch tolerance.

Education

Associate’s Degree in Mechanical Engineering Technology

October 2019

Skills

- Precision Measuring Equipment Operation

- Geometric Dimensioning and Tolerancing (GD&T)

- Computer-Aided Manufacturing (CAM) Programming

- Jig Boring Machine Operation

- Coordinate Measuring Machine (CMM) Operation

- Blueprint Reading and Interpretation

Work Experience

Jig Boring Machine Set-Up Operator

- Analyzed and optimized machining processes to improve efficiency and reduce production costs.

- Troubleshooted and resolved technical issues with the jig boring machine and tooling, minimizing downtime.

- Calibrated and maintained the jig boring machine to ensure accuracy and precision, adhering to industry standards.

- Utilized coordinate measuring machines (CMM) to verify the dimensions and quality of machined parts.

Jig Boring Machine Set-Up Operator

- Assembled and installed jig boring machines, ensuring accuracy and precision within 0.0001 inch tolerance.

- Operated a jig boring machine to create complex parts with intricate features, maintaining dimensional tolerances within specified requirements.

- Programmed and sequenced the CNC machine using advanced Gcode and CAM software to optimize toolpaths and reduce cycle times.

- Inspected and verified the accuracy of machined parts using precision measuring equipment, ensuring compliance with engineering specifications.

Accomplishments

- Consistently exceeded production targets by 15% through optimized setup and tool utilization.

- Implemented a new precision measurement technique, reducing setup time by 8%.

- Collaborated with engineering team to develop innovative fixturing solutions, enhancing accuracy.

- Introduced a comprehensive maintenance program, extending machine life and reducing downtime.

- Documented best practices for jig boring machine setup and operation, improving efficiency.

Awards

- Employee of the Month for consistently exceeding expectations and implementing innovative solutions.

- Safety Award for demonstrating outstanding safety practices and contributing to a safe work environment.

- Production Excellence Award for achieving exceptional production results and optimizing processes.

- Team Award for collaborating effectively and achieving a significant project milestone.

Certificates

- Certified Jig Boring Machine Operator

- Certified Geometric Dimensioning and Tolerancing (GD&T) Practitioner

- Certified Quality Control Inspector

- Certified Lean Manufacturing Specialist

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Jig Boring Machine Set-Up Operator

- Highlight your technical skills and experience in operating and programming jig boring machines.

- Quantify your accomplishments with specific metrics, such as reducing cycle times or improving accuracy.

- Emphasize your understanding of GD&T principles and their application in precision machining.

- Showcase your problem-solving abilities and experience troubleshooting and resolving technical issues.

- Demonstrate your commitment to quality and accuracy by mentioning your attention to detail and adherence to industry standards.

Essential Experience Highlights for a Strong Jig Boring Machine Set-Up Operator Resume

- Assembled and installed jig boring machines to specific dimensional requirements, ensuring accuracy and precision within 0.0001 inch tolerance.

- Programmed and sequenced CNC jig boring machines using advanced G-code and CAM software, optimizing toolpaths and reducing cycle times.

- Operated jig boring machines to create intricate and complex parts with tight tolerances, adhering to engineering specifications.

- Inspected and verified the accuracy of machined parts using precision measuring equipment, ensuring compliance with quality standards.

- Troubleshooted and resolved technical issues with jig boring machines and tooling, minimizing downtime and maintaining productivity.

- Analyzed and optimized machining processes to improve efficiency, reduce production costs, and enhance part quality.

- Utilized coordinate measuring machines (CMM) to verify the dimensions and quality of machined parts, ensuring accuracy and precision.

Frequently Asked Questions (FAQ’s) For Jig Boring Machine Set-Up Operator

What is the primary function of a Jig Boring Machine Set-Up Operator?

The primary function is to set up and operate jig boring machines to create intricate and complex parts with tight tolerances, ensuring accuracy and precision within 0.0001 inch tolerance.

What are the key skills required for a Jig Boring Machine Set-Up Operator?

Key skills include proficiency in precision measuring equipment operation, geometric dimensioning and tolerancing (GD&T), computer-aided manufacturing (CAM) programming, jig boring machine operation, coordinate measuring machine (CMM) operation, and blueprint reading and interpretation.

What industries utilize Jig Boring Machine Set-Up Operators?

Jig Boring Machine Set-Up Operators find employment in various industries, including aerospace, automotive, medical, and electronics manufacturing, where precision and accuracy are critical.

What is the career growth path for a Jig Boring Machine Set-Up Operator?

With experience and additional training, Jig Boring Machine Set-Up Operators can advance to roles such as CNC Programmer, Manufacturing Supervisor, or Quality Control Inspector.

What are the safety precautions that a Jig Boring Machine Set-Up Operator must observe?

Jig Boring Machine Set-Up Operators must adhere to strict safety protocols, including wearing appropriate personal protective equipment (PPE), following lockout/tagout procedures, and maintaining a clean and organized work area.

How does a Jig Boring Machine Set-Up Operator ensure the accuracy of machined parts?

To ensure accuracy, Jig Boring Machine Set-Up Operators utilize precision measuring equipment, such as micrometers, calipers, and coordinate measuring machines (CMMs), to verify the dimensions and quality of machined parts against engineering specifications.

What is the importance of GD&T for a Jig Boring Machine Set-Up Operator?

Geometric Dimensioning and Tolerancing (GD&T) is crucial for Jig Boring Machine Set-Up Operators as it provides a standardized language for communicating the precise dimensions, tolerances, and geometric characteristics required for manufactured parts.

How can a Jig Boring Machine Set-Up Operator stay updated with the latest industry trends?

To stay updated, Jig Boring Machine Set-Up Operators can attend industry conferences, read trade publications, and participate in training programs offered by equipment manufacturers and industry associations.