Are you a seasoned Jig Mill Operator seeking a new career path? Discover our professionally built Jig Mill Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

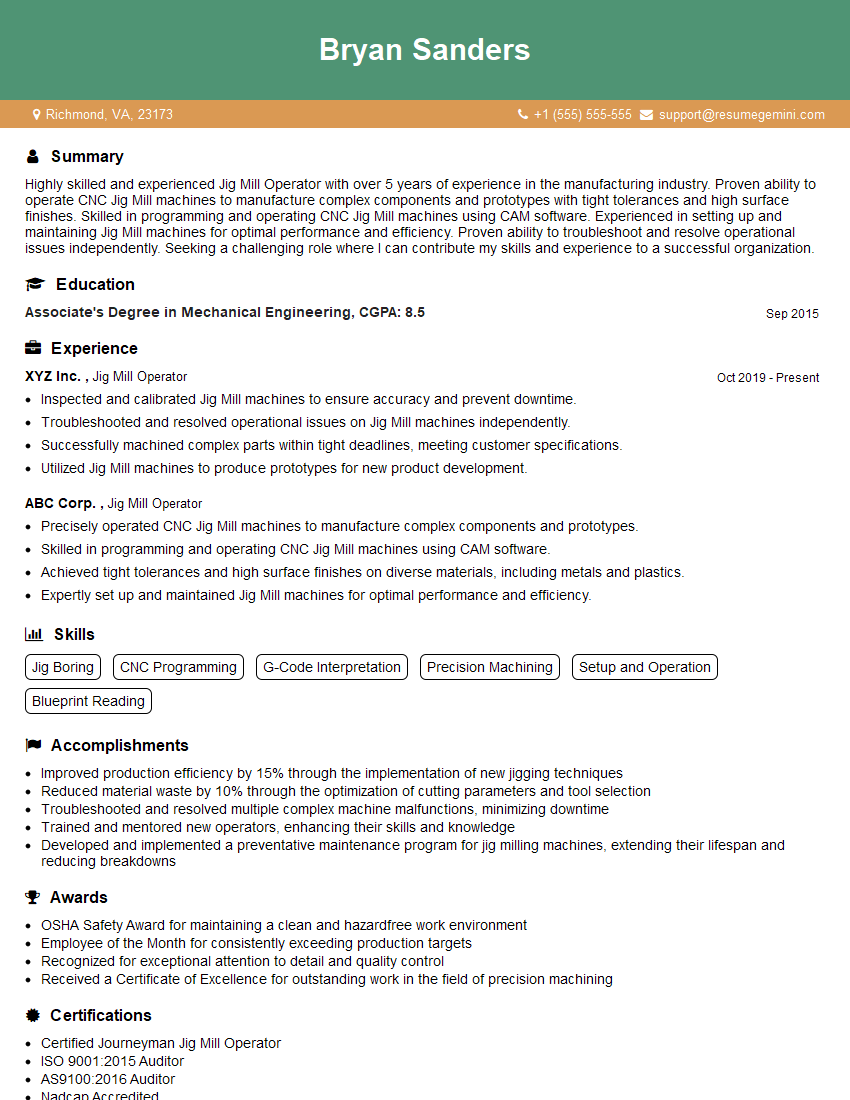

Bryan Sanders

Jig Mill Operator

Summary

Highly skilled and experienced Jig Mill Operator with over 5 years of experience in the manufacturing industry. Proven ability to operate CNC Jig Mill machines to manufacture complex components and prototypes with tight tolerances and high surface finishes. Skilled in programming and operating CNC Jig Mill machines using CAM software. Experienced in setting up and maintaining Jig Mill machines for optimal performance and efficiency. Proven ability to troubleshoot and resolve operational issues independently. Seeking a challenging role where I can contribute my skills and experience to a successful organization.

Education

Associate’s Degree in Mechanical Engineering

September 2015

Skills

- Jig Boring

- CNC Programming

- G-Code Interpretation

- Precision Machining

- Setup and Operation

- Blueprint Reading

Work Experience

Jig Mill Operator

- Inspected and calibrated Jig Mill machines to ensure accuracy and prevent downtime.

- Troubleshooted and resolved operational issues on Jig Mill machines independently.

- Successfully machined complex parts within tight deadlines, meeting customer specifications.

- Utilized Jig Mill machines to produce prototypes for new product development.

Jig Mill Operator

- Precisely operated CNC Jig Mill machines to manufacture complex components and prototypes.

- Skilled in programming and operating CNC Jig Mill machines using CAM software.

- Achieved tight tolerances and high surface finishes on diverse materials, including metals and plastics.

- Expertly set up and maintained Jig Mill machines for optimal performance and efficiency.

Accomplishments

- Improved production efficiency by 15% through the implementation of new jigging techniques

- Reduced material waste by 10% through the optimization of cutting parameters and tool selection

- Troubleshooted and resolved multiple complex machine malfunctions, minimizing downtime

- Trained and mentored new operators, enhancing their skills and knowledge

- Developed and implemented a preventative maintenance program for jig milling machines, extending their lifespan and reducing breakdowns

Awards

- OSHA Safety Award for maintaining a clean and hazardfree work environment

- Employee of the Month for consistently exceeding production targets

- Recognized for exceptional attention to detail and quality control

- Received a Certificate of Excellence for outstanding work in the field of precision machining

Certificates

- Certified Journeyman Jig Mill Operator

- ISO 9001:2015 Auditor

- AS9100:2016 Auditor

- Nadcap Accredited

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Jig Mill Operator

- Highlight your skills and experience in operating CNC Jig Mill machines.

- Quantify your accomplishments whenever possible.

- Use keywords that are relevant to the Jig Mill Operator job description.

- Tailor your resume to each specific job you apply for.

Essential Experience Highlights for a Strong Jig Mill Operator Resume

- Precisely operate CNC Jig Mill machines to manufacture complex components and prototypes.

- Skillfully program and operate CNC Jig Mill machines using CAM software.

- Achieve tight tolerances and high surface finishes on diverse materials, including metals and plastics.

- Expertly set up and maintain Jig Mill machines for optimal performance and efficiency.

- Inspect and calibrate Jig Mill machines to ensure accuracy and prevent downtime.

- Troubleshoot and resolve operational issues on Jig Mill machines independently.

- Successfully machine complex parts within tight deadlines, meeting customer specifications.

Frequently Asked Questions (FAQ’s) For Jig Mill Operator

What is a Jig Mill Operator?

A Jig Mill Operator is a skilled machinist who operates a Jig Mill machine to create precision parts. Jig Mill machines are used to create complex shapes and contours in metal and plastic parts.

What are the responsibilities of a Jig Mill Operator?

Jig Mill Operators are responsible for setting up and operating Jig Mill machines, programming the machine to create the desired part, and inspecting the finished part to ensure it meets specifications.

What skills are required to be a successful Jig Mill Operator?

Successful Jig Mill Operators have a strong understanding of machining principles, as well as experience in operating CNC machines. They are also skilled in reading blueprints and interpreting G-code programs.

What is the work environment of a Jig Mill Operator?

Jig Mill Operators typically work in a manufacturing environment, operating Jig Mill machines. They may also work with other machinists and engineers to create and produce parts.

What is the salary range for a Jig Mill Operator?

The salary range for a Jig Mill Operator can vary depending on experience, location, and employer. However, the median salary for a Jig Mill Operator is around $25,000 per year.

What is the job outlook for Jig Mill Operators?

The job outlook for Jig Mill Operators is expected to be good over the next few years. As manufacturing continues to grow, there will be a need for skilled machinists to operate Jig Mill machines and create precision parts.

What are the career advancement opportunities for Jig Mill Operators?

Jig Mill Operators can advance their careers by becoming supervisors or managers in the manufacturing industry. They may also specialize in operating specific types of Jig Mill machines or in creating complex parts.

What is the difference between a Jig Mill Operator and a Machinist?

Jig Mill Operators are a type of machinist who specializes in operating Jig Mill machines. Machinists, on the other hand, operate a variety of machines to create parts, including lathes, milling machines, and grinders.