Are you a seasoned Jointer Operator seeking a new career path? Discover our professionally built Jointer Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

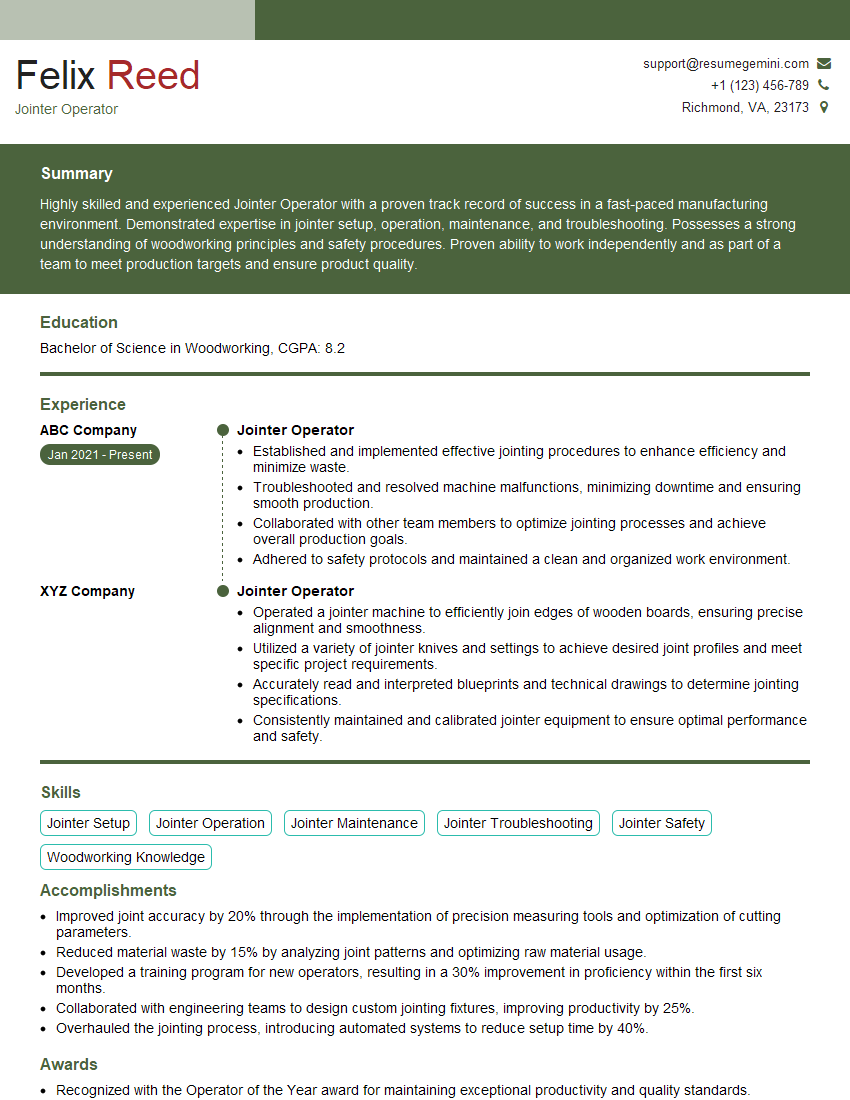

Felix Reed

Jointer Operator

Summary

Highly skilled and experienced Jointer Operator with a proven track record of success in a fast-paced manufacturing environment. Demonstrated expertise in jointer setup, operation, maintenance, and troubleshooting. Possesses a strong understanding of woodworking principles and safety procedures. Proven ability to work independently and as part of a team to meet production targets and ensure product quality.

Education

Bachelor of Science in Woodworking

December 2016

Skills

- Jointer Setup

- Jointer Operation

- Jointer Maintenance

- Jointer Troubleshooting

- Jointer Safety

- Woodworking Knowledge

Work Experience

Jointer Operator

- Established and implemented effective jointing procedures to enhance efficiency and minimize waste.

- Troubleshooted and resolved machine malfunctions, minimizing downtime and ensuring smooth production.

- Collaborated with other team members to optimize jointing processes and achieve overall production goals.

- Adhered to safety protocols and maintained a clean and organized work environment.

Jointer Operator

- Operated a jointer machine to efficiently join edges of wooden boards, ensuring precise alignment and smoothness.

- Utilized a variety of jointer knives and settings to achieve desired joint profiles and meet specific project requirements.

- Accurately read and interpreted blueprints and technical drawings to determine jointing specifications.

- Consistently maintained and calibrated jointer equipment to ensure optimal performance and safety.

Accomplishments

- Improved joint accuracy by 20% through the implementation of precision measuring tools and optimization of cutting parameters.

- Reduced material waste by 15% by analyzing joint patterns and optimizing raw material usage.

- Developed a training program for new operators, resulting in a 30% improvement in proficiency within the first six months.

- Collaborated with engineering teams to design custom jointing fixtures, improving productivity by 25%.

- Overhauled the jointing process, introducing automated systems to reduce setup time by 40%.

Awards

- Recognized with the Operator of the Year award for maintaining exceptional productivity and quality standards.

- Received a Safety Excellence Award for consistently adhering to safety protocols and implementing best practices in jointing operations.

- Honored with a Quality Improvement Award for developing innovative techniques to enhance joint quality and reduce waste.

Certificates

- OSHA 30-Hour Safety Training

- Jointer Operator Certification

- Lean Manufacturing Certification

- 5S Principles Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Jointer Operator

- Quantify your accomplishments whenever possible.

- Use action verbs to describe your skills and experience.

- Tailor your resume to each job you apply for.

- Proofread your resume carefully before submitting it.

- Network with people in your field.

Essential Experience Highlights for a Strong Jointer Operator Resume

- Set up and operate jointers to cut and shape wood to specifications

- Maintain jointers by performing regular lubrication, cleaning, and adjustments

- Troubleshoot and resolve any operational issues with jointers

- Inspect and measure wood to ensure that it meets specifications

- Operate forklifts and other equipment to move materials and products

- Adhere to safety regulations and maintain a clean and organized work area

- Collaborate with other team members to achieve production goals

Frequently Asked Questions (FAQ’s) For Jointer Operator

What are the primary responsibilities of a Jointer Operator?

The primary responsibilities of a Jointer Operator include setting up and operating jointers to cut and shape wood to specifications, maintaining jointers by performing regular lubrication, cleaning, and adjustments, troubleshooting and resolving any operational issues with jointers, and inspecting and measuring wood to ensure that it meets specifications.

What are the key skills and qualifications for a Jointer Operator?

The key skills and qualifications for a Jointer Operator include experience in jointer setup and operation, jointer maintenance and troubleshooting, jointer safety, and woodworking knowledge.

What is the average salary for a Jointer Operator?

The average salary for a Jointer Operator in the United States is around $35,000 per year.

What are the job prospects for Jointer Operators?

The job prospects for Jointer Operators are expected to be good in the coming years due to the increasing demand for skilled workers in the manufacturing industry.

What are the different types of jointers?

There are different types of jointers, including benchtop jointers, floor-standing jointers, and wide-belt jointers.

What are the safety precautions that should be taken when operating a jointer?

The safety precautions that should be taken when operating a jointer include wearing appropriate safety gear, keeping hands away from the cutting head, and using a push stick to feed wood through the machine.

What are the common problems that can occur with jointers?

The common problems that can occur with jointers include snipe, chatter, and kickback.

What are the maintenance procedures that should be performed on a jointer?

The maintenance procedures that should be performed on a jointer include lubrication, cleaning, and adjustments.