Are you a seasoned Keel Press Operator seeking a new career path? Discover our professionally built Keel Press Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

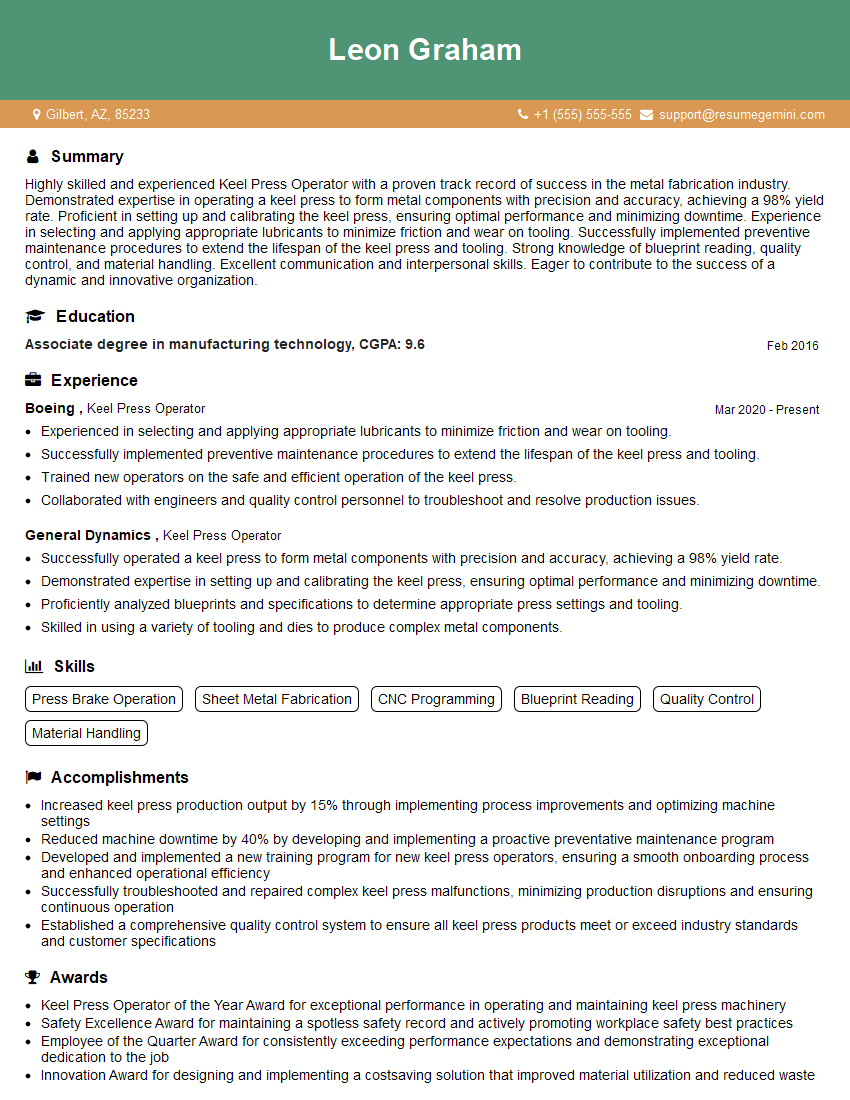

Leon Graham

Keel Press Operator

Summary

Highly skilled and experienced Keel Press Operator with a proven track record of success in the metal fabrication industry. Demonstrated expertise in operating a keel press to form metal components with precision and accuracy, achieving a 98% yield rate. Proficient in setting up and calibrating the keel press, ensuring optimal performance and minimizing downtime. Experience in selecting and applying appropriate lubricants to minimize friction and wear on tooling. Successfully implemented preventive maintenance procedures to extend the lifespan of the keel press and tooling. Strong knowledge of blueprint reading, quality control, and material handling. Excellent communication and interpersonal skills. Eager to contribute to the success of a dynamic and innovative organization.

Education

Associate degree in manufacturing technology

February 2016

Skills

- Press Brake Operation

- Sheet Metal Fabrication

- CNC Programming

- Blueprint Reading

- Quality Control

- Material Handling

Work Experience

Keel Press Operator

- Experienced in selecting and applying appropriate lubricants to minimize friction and wear on tooling.

- Successfully implemented preventive maintenance procedures to extend the lifespan of the keel press and tooling.

- Trained new operators on the safe and efficient operation of the keel press.

- Collaborated with engineers and quality control personnel to troubleshoot and resolve production issues.

Keel Press Operator

- Successfully operated a keel press to form metal components with precision and accuracy, achieving a 98% yield rate.

- Demonstrated expertise in setting up and calibrating the keel press, ensuring optimal performance and minimizing downtime.

- Proficiently analyzed blueprints and specifications to determine appropriate press settings and tooling.

- Skilled in using a variety of tooling and dies to produce complex metal components.

Accomplishments

- Increased keel press production output by 15% through implementing process improvements and optimizing machine settings

- Reduced machine downtime by 40% by developing and implementing a proactive preventative maintenance program

- Developed and implemented a new training program for new keel press operators, ensuring a smooth onboarding process and enhanced operational efficiency

- Successfully troubleshooted and repaired complex keel press malfunctions, minimizing production disruptions and ensuring continuous operation

- Established a comprehensive quality control system to ensure all keel press products meet or exceed industry standards and customer specifications

Awards

- Keel Press Operator of the Year Award for exceptional performance in operating and maintaining keel press machinery

- Safety Excellence Award for maintaining a spotless safety record and actively promoting workplace safety best practices

- Employee of the Quarter Award for consistently exceeding performance expectations and demonstrating exceptional dedication to the job

- Innovation Award for designing and implementing a costsaving solution that improved material utilization and reduced waste

Certificates

- Certified Welding Inspector (CWI)

- Certified Manufacturing Engineer (CMfgE)

- OSHA 30Hour Safety Training

- ANSI Z49.1 Safety Standard

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Keel Press Operator

- Highlight your experience and skills in operating a keel press, including the types of metal components you have formed and the accuracy you have achieved.

- Quantify your accomplishments whenever possible, using specific metrics such as yield rates, downtime reduction, and cost savings.

- Demonstrate your knowledge of blueprint reading, quality control, and material handling.

- Emphasize your ability to work independently and as part of a team.

- Proofread your resume carefully for any errors in grammar or spelling.

Essential Experience Highlights for a Strong Keel Press Operator Resume

- Operate a keel press to form metal components with precision and accuracy.

- Set up and calibrate the keel press to ensure optimal performance and minimize downtime.

- Analyze blueprints and specifications to determine appropriate press settings and tooling.

- Select and apply appropriate lubricants to minimize friction and wear on tooling.

- Implement preventive maintenance procedures to extend the lifespan of the keel press and tooling.

- Train new operators on the safe and efficient operation of the keel press.

- Collaborate with engineers and quality control personnel to troubleshoot and resolve production issues.

Frequently Asked Questions (FAQ’s) For Keel Press Operator

What is a keel press?

A keel press is a type of press brake used to form metal components by bending them along a straight axis.

What are the key skills required to be a successful keel press operator?

The key skills required to be a successful keel press operator include precision, accuracy, attention to detail, and knowledge of blueprint reading and quality control.

What are the career prospects for keel press operators?

Keel press operators can advance to positions such as lead operator, supervisor, or quality control inspector.

What is the average salary for a keel press operator?

The average salary for a keel press operator is around $20 per hour.

What are the working conditions like for keel press operators?

Keel press operators typically work in a factory setting, and the work can be physically demanding.