Are you a seasoned Keyseating Machine Set Up Operator seeking a new career path? Discover our professionally built Keyseating Machine Set Up Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

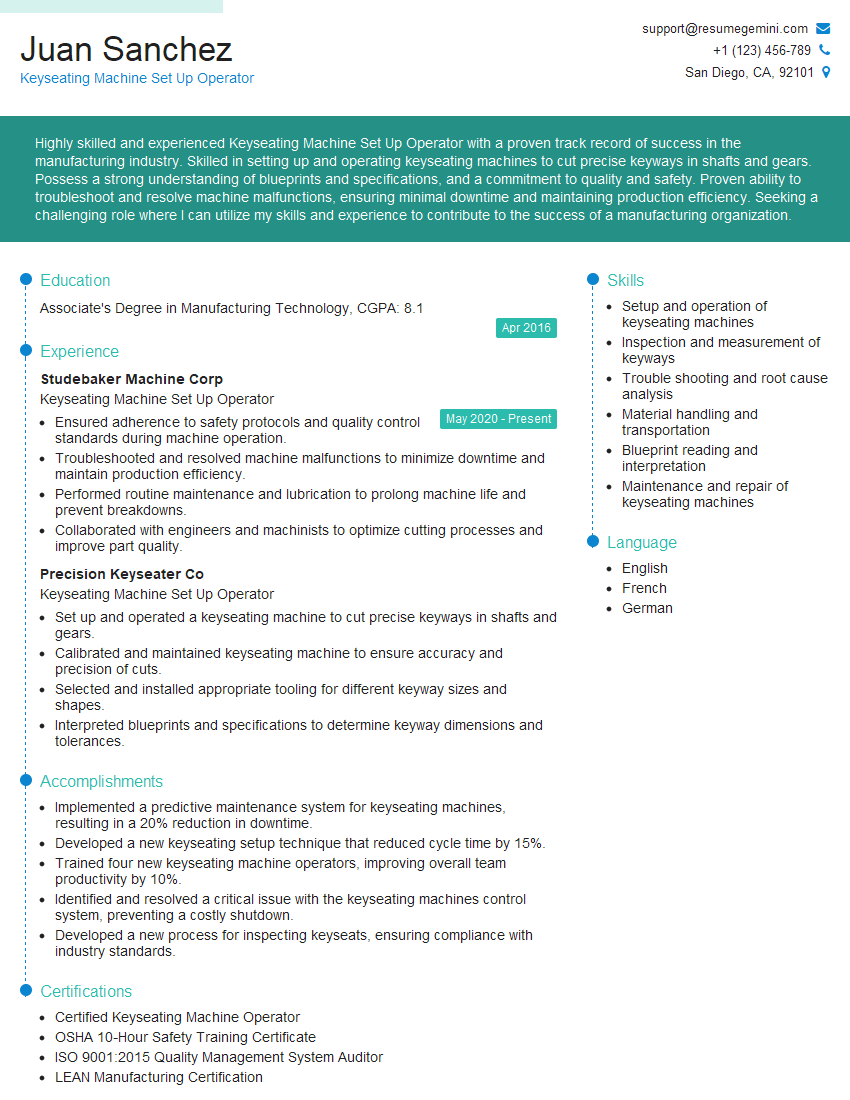

Juan Sanchez

Keyseating Machine Set Up Operator

Summary

Highly skilled and experienced Keyseating Machine Set Up Operator with a proven track record of success in the manufacturing industry. Skilled in setting up and operating keyseating machines to cut precise keyways in shafts and gears. Possess a strong understanding of blueprints and specifications, and a commitment to quality and safety. Proven ability to troubleshoot and resolve machine malfunctions, ensuring minimal downtime and maintaining production efficiency. Seeking a challenging role where I can utilize my skills and experience to contribute to the success of a manufacturing organization.

Education

Associate’s Degree in Manufacturing Technology

April 2016

Skills

- Setup and operation of keyseating machines

- Inspection and measurement of keyways

- Trouble shooting and root cause analysis

- Material handling and transportation

- Blueprint reading and interpretation

- Maintenance and repair of keyseating machines

Work Experience

Keyseating Machine Set Up Operator

- Ensured adherence to safety protocols and quality control standards during machine operation.

- Troubleshooted and resolved machine malfunctions to minimize downtime and maintain production efficiency.

- Performed routine maintenance and lubrication to prolong machine life and prevent breakdowns.

- Collaborated with engineers and machinists to optimize cutting processes and improve part quality.

Keyseating Machine Set Up Operator

- Set up and operated a keyseating machine to cut precise keyways in shafts and gears.

- Calibrated and maintained keyseating machine to ensure accuracy and precision of cuts.

- Selected and installed appropriate tooling for different keyway sizes and shapes.

- Interpreted blueprints and specifications to determine keyway dimensions and tolerances.

Accomplishments

- Implemented a predictive maintenance system for keyseating machines, resulting in a 20% reduction in downtime.

- Developed a new keyseating setup technique that reduced cycle time by 15%.

- Trained four new keyseating machine operators, improving overall team productivity by 10%.

- Identified and resolved a critical issue with the keyseating machines control system, preventing a costly shutdown.

- Developed a new process for inspecting keyseats, ensuring compliance with industry standards.

Certificates

- Certified Keyseating Machine Operator

- OSHA 10-Hour Safety Training Certificate

- ISO 9001:2015 Quality Management System Auditor

- LEAN Manufacturing Certification

Languages

- English

- French

- German

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Keyseating Machine Set Up Operator

- Highlight your experience and skills in setting up and operating keyseating machines.

- Quantify your accomplishments whenever possible, using specific metrics to demonstrate your impact.

- Include keywords from the job description in your resume to ensure it gets noticed by potential employers.

- Proofread your resume carefully before submitting it to ensure there are no errors.

Essential Experience Highlights for a Strong Keyseating Machine Set Up Operator Resume

- Set up and operated a keyseating machine to cut precise keyways in shafts and gears.

- Calibrated and maintained keyseating machine to ensure accuracy and precision of cuts.

- Selected and installed appropriate tooling for different keyway sizes and shapes.

- Interpreted blueprints and specifications to determine keyway dimensions and tolerances.

- Ensured adherence to safety protocols and quality control standards during machine operation.

- Troubleshooted and resolved machine malfunctions to minimize downtime and maintain production efficiency.

Frequently Asked Questions (FAQ’s) For Keyseating Machine Set Up Operator

What is a keyseating machine?

A keyseating machine is a machine tool used to cut keyways, which are slots or grooves cut into the surface of a shaft or gear to accommodate a key or other mating part.

What are the different types of keyseating machines?

There are two main types of keyseating machines: horizontal and vertical. Horizontal keyseating machines are used for cutting keyways in shafts, while vertical keyseating machines are used for cutting keyways in gears.

What are the advantages of using a keyseating machine?

Keyseating machines offer a number of advantages over manual methods of cutting keyways, including increased accuracy and precision, reduced production time, and improved safety.

What are the safety precautions that should be taken when operating a keyseating machine?

When operating a keyseating machine, it is important to wear appropriate safety gear, including safety glasses, gloves, and hearing protection. It is also important to keep the work area clean and free of debris, and to follow all manufacturer’s instructions for safe operation.

What are the key skills and qualifications required for a Keyseating Machine Set Up Operator?

Key skills and qualifications for a Keyseating Machine Set Up Operator include experience in setting up and operating keyseating machines, knowledge of blueprint reading and interpretation, experience in troubleshooting and resolving machine malfunctions, and a commitment to safety and quality.