Are you a seasoned Ladle Car Operator seeking a new career path? Discover our professionally built Ladle Car Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

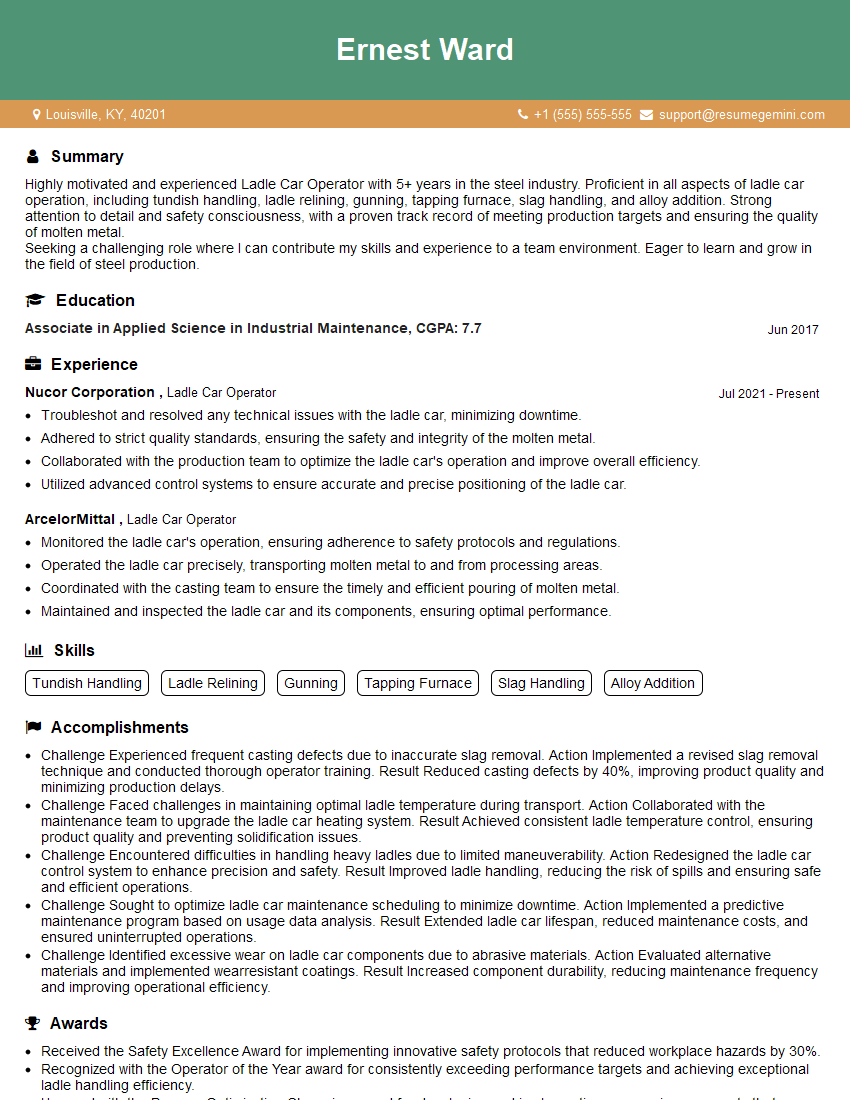

Ernest Ward

Ladle Car Operator

Summary

Highly motivated and experienced Ladle Car Operator with 5+ years in the steel industry. Proficient in all aspects of ladle car operation, including tundish handling, ladle relining, gunning, tapping furnace, slag handling, and alloy addition. Strong attention to detail and safety consciousness, with a proven track record of meeting production targets and ensuring the quality of molten metal.

Seeking a challenging role where I can contribute my skills and experience to a team environment. Eager to learn and grow in the field of steel production.

Education

Associate in Applied Science in Industrial Maintenance

June 2017

Skills

- Tundish Handling

- Ladle Relining

- Gunning

- Tapping Furnace

- Slag Handling

- Alloy Addition

Work Experience

Ladle Car Operator

- Troubleshot and resolved any technical issues with the ladle car, minimizing downtime.

- Adhered to strict quality standards, ensuring the safety and integrity of the molten metal.

- Collaborated with the production team to optimize the ladle car’s operation and improve overall efficiency.

- Utilized advanced control systems to ensure accurate and precise positioning of the ladle car.

Ladle Car Operator

- Monitored the ladle car’s operation, ensuring adherence to safety protocols and regulations.

- Operated the ladle car precisely, transporting molten metal to and from processing areas.

- Coordinated with the casting team to ensure the timely and efficient pouring of molten metal.

- Maintained and inspected the ladle car and its components, ensuring optimal performance.

Accomplishments

- Challenge Experienced frequent casting defects due to inaccurate slag removal. Action Implemented a revised slag removal technique and conducted thorough operator training. Result Reduced casting defects by 40%, improving product quality and minimizing production delays.

- Challenge Faced challenges in maintaining optimal ladle temperature during transport. Action Collaborated with the maintenance team to upgrade the ladle car heating system. Result Achieved consistent ladle temperature control, ensuring product quality and preventing solidification issues.

- Challenge Encountered difficulties in handling heavy ladles due to limited maneuverability. Action Redesigned the ladle car control system to enhance precision and safety. Result Improved ladle handling, reducing the risk of spills and ensuring safe and efficient operations.

- Challenge Sought to optimize ladle car maintenance scheduling to minimize downtime. Action Implemented a predictive maintenance program based on usage data analysis. Result Extended ladle car lifespan, reduced maintenance costs, and ensured uninterrupted operations.

- Challenge Identified excessive wear on ladle car components due to abrasive materials. Action Evaluated alternative materials and implemented wearresistant coatings. Result Increased component durability, reducing maintenance frequency and improving operational efficiency.

Awards

- Received the Safety Excellence Award for implementing innovative safety protocols that reduced workplace hazards by 30%.

- Recognized with the Operator of the Year award for consistently exceeding performance targets and achieving exceptional ladle handling efficiency.

- Honored with the Process Optimization Champion award for developing and implementing process improvements that enhanced ladle car operations and increased production output by 15%.

Certificates

- Crane Operator Certification

- Ladle Car Operator Certification

- First Aid and CPR Certification

- Forklift Operator Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Ladle Car Operator

Highlight your skills and experience.

Make sure your resume clearly outlines your skills and experience as a Ladle Car Operator. This includes your experience in tundish handling, ladle relining, gunning, tapping furnace, slag handling, and alloy addition.

Quantify your accomplishments.

Whenever possible, quantify your accomplishments to demonstrate your impact on the job. For example, you could mention the number of ladles you operated per shift or the amount of molten metal you transported.

Proofread carefully.

Before submitting your resume, proofread it carefully to check for any errors. This includes checking for spelling, grammar, and punctuation errors.

Tailor your resume to each job.

When applying for a job, tailor your resume to the specific requirements of the position. This means highlighting the skills and experience that are most relevant to the job you’re applying for.

Essential Experience Highlights for a Strong Ladle Car Operator Resume

- Operate ladle car to transport molten metal from the furnace to the tundish.

- Prepare and maintain ladle refractories to ensure the quality of molten metal.

- Handle and dispose of slag and other waste materials in a safe and environmentally sound manner.

- Add alloys and other materials to the molten metal to meet specified chemical compositions.

- Monitor and control ladle car temperature and other process parameters to ensure optimal performance.

- Collaborate with other operators and supervisors to ensure smooth and efficient production.

- Adhere to all safety regulations and procedures to maintain a safe work environment.

Frequently Asked Questions (FAQ’s) For Ladle Car Operator

What are the key skills required to be a successful Ladle Car Operator?

The key skills required to be a successful Ladle Car Operator include the ability to operate ladle cars safely and efficiently, as well as the ability to handle and dispose of slag and other waste materials in a safe and environmentally sound manner. Additionally, Ladle Car Operators must be able to add alloys and other materials to the molten metal to meet specified chemical compositions, and monitor and control ladle car temperature and other process parameters to ensure optimal performance.

What are the career prospects for Ladle Car Operators?

The career prospects for Ladle Car Operators are good. With experience, Ladle Car Operators can move into supervisory or management positions. Additionally, Ladle Car Operators can also move into other related fields, such as quality control or maintenance.

What is the work environment for Ladle Car Operators like?

The work environment for Ladle Car Operators is typically hot and noisy. Ladle Car Operators must also be able to work in a team environment and be able to follow instructions from supervisors.

What are the physical demands of being a Ladle Car Operator?

The physical demands of being a Ladle Car Operator can be demanding. Ladle Car Operators must be able to stand for long periods of time, lift heavy objects, and work in a hot and noisy environment.

What is the average salary for a Ladle Car Operator?

The average salary for a Ladle Car Operator is $55,000 per year.

What are the benefits of being a Ladle Car Operator?

The benefits of being a Ladle Car Operator include a good salary, benefits package, and the opportunity to work in a challenging and rewarding field.