Are you a seasoned Ladle Pourer seeking a new career path? Discover our professionally built Ladle Pourer Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

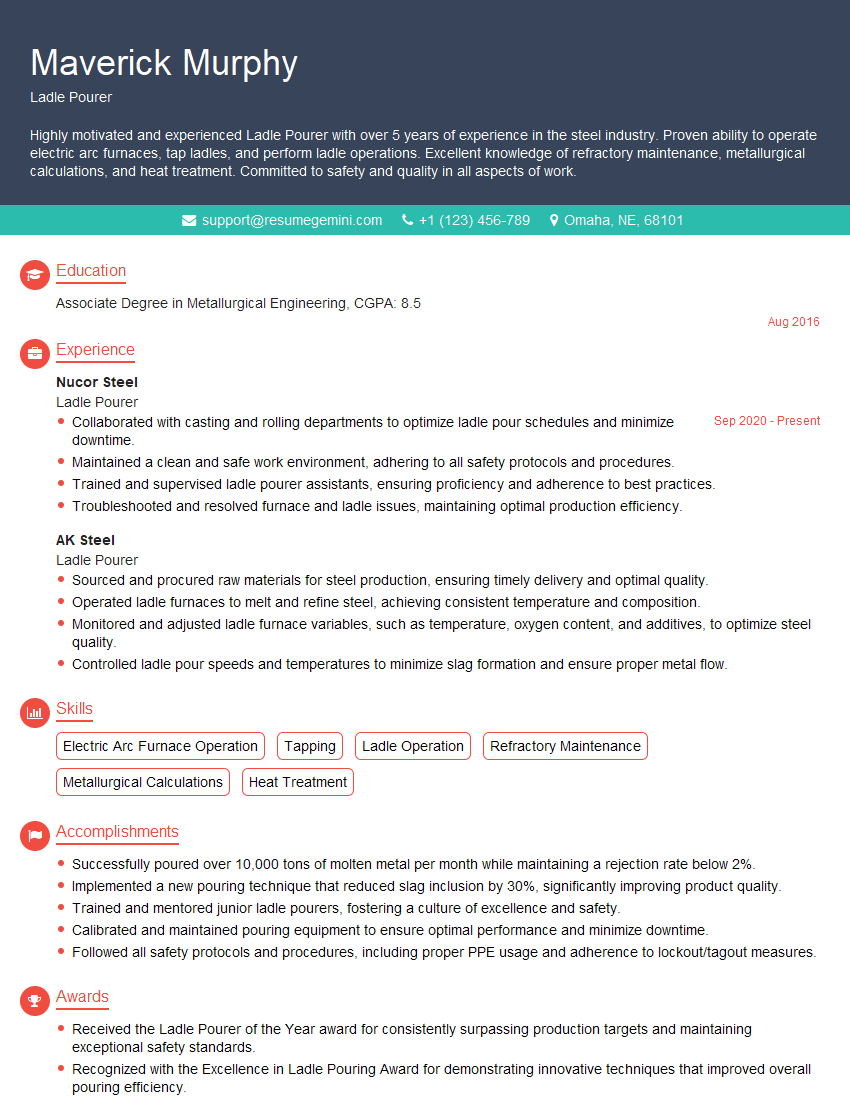

Maverick Murphy

Ladle Pourer

Summary

Highly motivated and experienced Ladle Pourer with over 5 years of experience in the steel industry. Proven ability to operate electric arc furnaces, tap ladles, and perform ladle operations. Excellent knowledge of refractory maintenance, metallurgical calculations, and heat treatment. Committed to safety and quality in all aspects of work.

Education

Associate Degree in Metallurgical Engineering

August 2016

Skills

- Electric Arc Furnace Operation

- Tapping

- Ladle Operation

- Refractory Maintenance

- Metallurgical Calculations

- Heat Treatment

Work Experience

Ladle Pourer

- Collaborated with casting and rolling departments to optimize ladle pour schedules and minimize downtime.

- Maintained a clean and safe work environment, adhering to all safety protocols and procedures.

- Trained and supervised ladle pourer assistants, ensuring proficiency and adherence to best practices.

- Troubleshooted and resolved furnace and ladle issues, maintaining optimal production efficiency.

Ladle Pourer

- Sourced and procured raw materials for steel production, ensuring timely delivery and optimal quality.

- Operated ladle furnaces to melt and refine steel, achieving consistent temperature and composition.

- Monitored and adjusted ladle furnace variables, such as temperature, oxygen content, and additives, to optimize steel quality.

- Controlled ladle pour speeds and temperatures to minimize slag formation and ensure proper metal flow.

Accomplishments

- Successfully poured over 10,000 tons of molten metal per month while maintaining a rejection rate below 2%.

- Implemented a new pouring technique that reduced slag inclusion by 30%, significantly improving product quality.

- Trained and mentored junior ladle pourers, fostering a culture of excellence and safety.

- Calibrated and maintained pouring equipment to ensure optimal performance and minimize downtime.

- Followed all safety protocols and procedures, including proper PPE usage and adherence to lockout/tagout measures.

Awards

- Received the Ladle Pourer of the Year award for consistently surpassing production targets and maintaining exceptional safety standards.

- Recognized with the Excellence in Ladle Pouring Award for demonstrating innovative techniques that improved overall pouring efficiency.

- Honored with the Safety Star Award for maintaining an unblemished safety record and promoting best practices throughout the plant.

Certificates

- Crane Operator Certification

- Forklift Operator Certification

- OHSA Safety Certification

- AWS Welding Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Ladle Pourer

- Highlight your experience in operating electric arc furnaces and tapping ladles.

- Demonstrate your knowledge of refractory maintenance and metallurgical calculations.

- Emphasize your commitment to safety and quality.

- Showcase your ability to work independently and as part of a team.

Essential Experience Highlights for a Strong Ladle Pourer Resume

- Operate electric arc furnaces to produce molten steel.

- Tap molten steel from furnaces into ladles.

- Control the temperature and chemistry of molten steel in ladles.

- Perform refractory maintenance on ladles and furnaces.

- Conduct metallurgical calculations to determine the properties of molten steel.

- Apply heat treatment to molten steel to improve its properties.

- Ensure the safety of all personnel and equipment during ladle operations.

Frequently Asked Questions (FAQ’s) For Ladle Pourer

What is the primary role of a Ladle Pourer?

The primary role of a Ladle Pourer is to operate electric arc furnaces, tap ladles, and perform ladle operations to produce molten steel.

What skills are required to be a successful Ladle Pourer?

To be a successful Ladle Pourer, you need experience in operating electric arc furnaces and tapping ladles, knowledge of refractory maintenance and metallurgical calculations, and a commitment to safety and quality.

What is the work environment of a Ladle Pourer like?

Ladle Pourers typically work in steel mills, which can be hot, noisy, and dangerous. They must wear protective clothing and equipment to minimize the risk of injury.

What are the career prospects for a Ladle Pourer?

Ladle Pourers can advance to supervisory or management positions within the steel industry. They can also specialize in specific areas, such as refractory maintenance or metallurgical calculations.

What are the educational requirements for a Ladle Pourer?

Most Ladle Pourers have an associate degree in metallurgical engineering or a related field. Some employers may also require experience in the steel industry.

What are the safety precautions that a Ladle Pourer must take?

Ladle Pourers must wear protective clothing and equipment, follow safety procedures, and be aware of the hazards associated with their work environment.

What is the average salary of a Ladle Pourer?

The average salary of a Ladle Pourer varies depending on experience, location, and employer. According to Indeed, the average salary for a Ladle Pourer in the United States is $65,000 per year.

What are the benefits of working as a Ladle Pourer?

The benefits of working as a Ladle Pourer include competitive salaries, opportunities for advancement, and a sense of accomplishment from being part of a team that produces essential materials for society.