Are you a seasoned Lathe Machinist seeking a new career path? Discover our professionally built Lathe Machinist Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

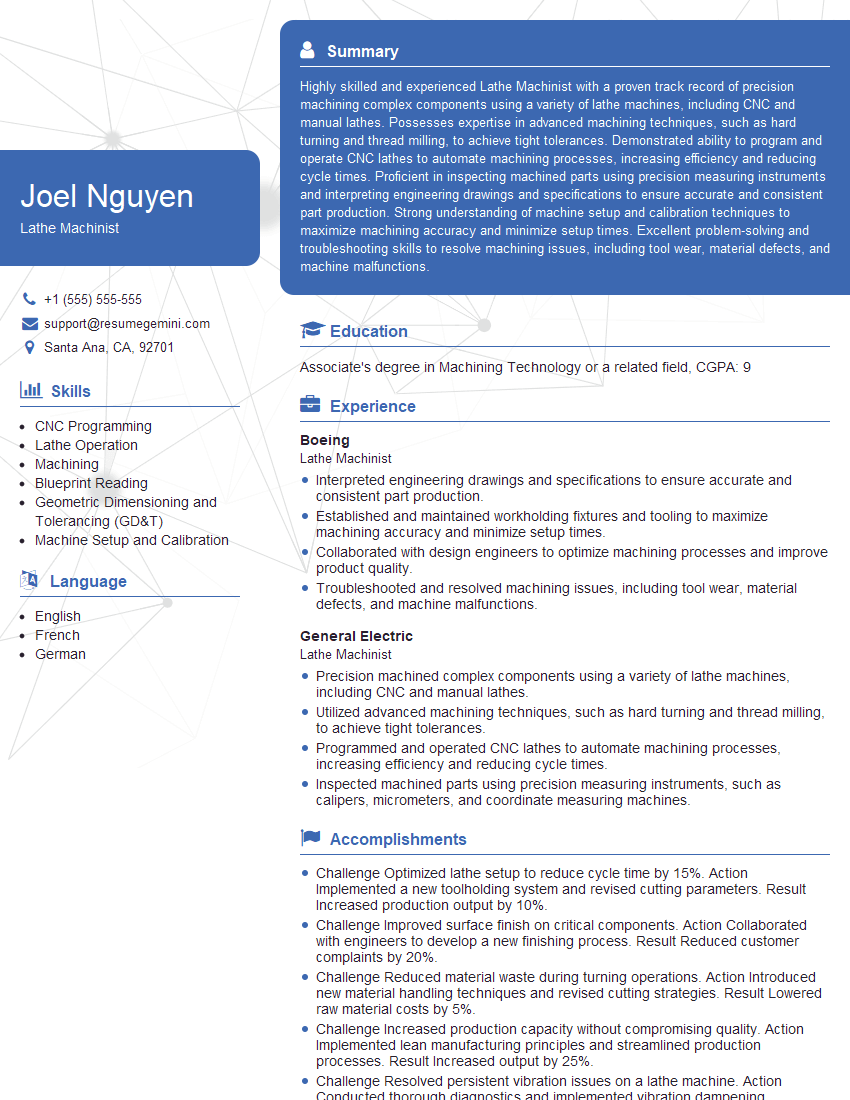

Joel Nguyen

Lathe Machinist

Summary

Highly skilled and experienced Lathe Machinist with a proven track record of precision machining complex components using a variety of lathe machines, including CNC and manual lathes. Possesses expertise in advanced machining techniques, such as hard turning and thread milling, to achieve tight tolerances. Demonstrated ability to program and operate CNC lathes to automate machining processes, increasing efficiency and reducing cycle times. Proficient in inspecting machined parts using precision measuring instruments and interpreting engineering drawings and specifications to ensure accurate and consistent part production. Strong understanding of machine setup and calibration techniques to maximize machining accuracy and minimize setup times. Excellent problem-solving and troubleshooting skills to resolve machining issues, including tool wear, material defects, and machine malfunctions.

Education

Associate’s degree in Machining Technology or a related field

December 2017

Skills

- CNC Programming

- Lathe Operation

- Machining

- Blueprint Reading

- Geometric Dimensioning and Tolerancing (GD&T)

- Machine Setup and Calibration

Work Experience

Lathe Machinist

- Interpreted engineering drawings and specifications to ensure accurate and consistent part production.

- Established and maintained workholding fixtures and tooling to maximize machining accuracy and minimize setup times.

- Collaborated with design engineers to optimize machining processes and improve product quality.

- Troubleshooted and resolved machining issues, including tool wear, material defects, and machine malfunctions.

Lathe Machinist

- Precision machined complex components using a variety of lathe machines, including CNC and manual lathes.

- Utilized advanced machining techniques, such as hard turning and thread milling, to achieve tight tolerances.

- Programmed and operated CNC lathes to automate machining processes, increasing efficiency and reducing cycle times.

- Inspected machined parts using precision measuring instruments, such as calipers, micrometers, and coordinate measuring machines.

Accomplishments

- Challenge Optimized lathe setup to reduce cycle time by 15%. Action Implemented a new toolholding system and revised cutting parameters. Result Increased production output by 10%.

- Challenge Improved surface finish on critical components. Action Collaborated with engineers to develop a new finishing process. Result Reduced customer complaints by 20%.

- Challenge Reduced material waste during turning operations. Action Introduced new material handling techniques and revised cutting strategies. Result Lowered raw material costs by 5%.

- Challenge Increased production capacity without compromising quality. Action Implemented lean manufacturing principles and streamlined production processes. Result Increased output by 25%.

- Challenge Resolved persistent vibration issues on a lathe machine. Action Conducted thorough diagnostics and implemented vibration dampening techniques. Result Restored machine stability and improved part quality.

Awards

- Received the Lathe Machinist of the Year award for consistently exceeding production targets and maintaining highquality standards.

- Recognized for achieving a 10% reduction in production time through innovative tooling techniques.

- Awarded the Safety Champion award for implementing proactive measures that reduced workplace accidents.

- Recognized by the company for exceptional precision and accuracy in machining complex parts.

Certificates

- Journeyman Lathe Machinist

- National Institute for Metalworking Skills (NIMS) Machining Level II

- American Welding Society (AWS) Certified Welder

- Occupational Safety and Health Administration (OSHA) 30-Hour Safety Training

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Lathe Machinist

- Highlight your skills and experience in operating CNC lathes and other machining equipment.

- Demonstrate your knowledge of advanced machining techniques and your ability to achieve tight tolerances.

- Provide examples of how you have improved efficiency and reduced cycle times through automation.

- Emphasize your ability to inspect machined parts accurately and ensure consistent quality.

- Showcase your problem-solving and troubleshooting skills, and your ability to work independently and as part of a team.

Essential Experience Highlights for a Strong Lathe Machinist Resume

- Precision machined complex components using a variety of lathe machines, including CNC and manual lathes

- Utilized advanced machining techniques, such as hard turning and thread milling, to achieve tight tolerances

- Programmed and operated CNC lathes to automate machining processes, increasing efficiency and reducing cycle times

- Inspected machined parts using precision measuring instruments, such as calipers, micrometers, and coordinate measuring machines

- Interpreted engineering drawings and specifications to ensure accurate and consistent part production

- Established and maintained workholding fixtures and tooling to maximize machining accuracy and minimize setup times

- Collaborated with design engineers to optimize machining processes and improve product quality.

- Troubleshooted and resolved machining issues, including tool wear, material defects, and machine malfunctions

Frequently Asked Questions (FAQ’s) For Lathe Machinist

What are the key skills required for a Lathe Machinist?

The key skills required for a Lathe Machinist include CNC programming, lathe operation, machining, blueprint reading, geometric dimensioning and tolerancing (GD&T), machine setup and calibration, and troubleshooting.

What are the typical responsibilities of a Lathe Machinist?

The typical responsibilities of a Lathe Machinist include setting up and operating CNC lathes and other machining equipment, programming CNC lathes to automate machining processes, inspecting machined parts to ensure quality, troubleshooting and resolving machining issues, and maintaining workholding fixtures and tooling.

What are the career prospects for a Lathe Machinist?

The career prospects for a Lathe Machinist are good, with a growing demand for skilled machinists in various industries, such as manufacturing, aerospace, and automotive.

What is the average salary for a Lathe Machinist?

The average salary for a Lathe Machinist varies depending on experience, location, and industry, but typically ranges from $25,000 to $50,000 per year.

What are the educational requirements for a Lathe Machinist?

Most Lathe Machinists have a high school diploma or equivalent, although some employers may require an associate’s degree in machining technology or a related field.

What are the certifications available for Lathe Machinists?

There are several certifications available for Lathe Machinists, including the Certified Manufacturing Technologist (CMfgT) certification from the Society of Manufacturing Engineers (SME) and the National Institute for Metalworking Skills (NIMS) credentials.

What are the advancement opportunities for a Lathe Machinist?

Lathe Machinists can advance to positions such as CNC Programmer, Manufacturing Engineer, or Quality Control Inspector.

What are the safety precautions that Lathe Machinists must follow?

Lathe Machinists must follow safety precautions such as wearing appropriate safety gear, keeping the work area clean and organized, and being aware of potential hazards such as rotating machinery and sharp tools.