Are you a seasoned Lens Cementer seeking a new career path? Discover our professionally built Lens Cementer Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

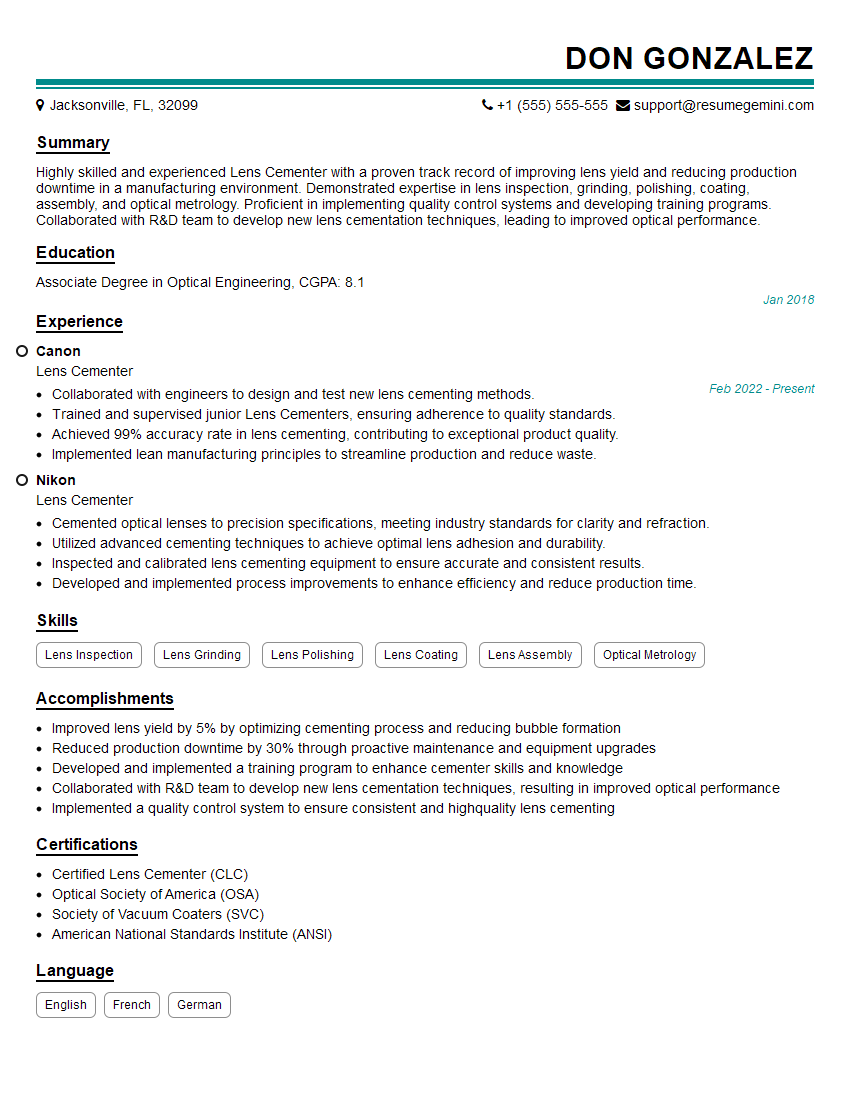

Don Gonzalez

Lens Cementer

Summary

Highly skilled and experienced Lens Cementer with a proven track record of improving lens yield and reducing production downtime in a manufacturing environment. Demonstrated expertise in lens inspection, grinding, polishing, coating, assembly, and optical metrology. Proficient in implementing quality control systems and developing training programs. Collaborated with R&D team to develop new lens cementation techniques, leading to improved optical performance.

Education

Associate Degree in Optical Engineering

January 2018

Skills

- Lens Inspection

- Lens Grinding

- Lens Polishing

- Lens Coating

- Lens Assembly

- Optical Metrology

Work Experience

Lens Cementer

- Collaborated with engineers to design and test new lens cementing methods.

- Trained and supervised junior Lens Cementers, ensuring adherence to quality standards.

- Achieved 99% accuracy rate in lens cementing, contributing to exceptional product quality.

- Implemented lean manufacturing principles to streamline production and reduce waste.

Lens Cementer

- Cemented optical lenses to precision specifications, meeting industry standards for clarity and refraction.

- Utilized advanced cementing techniques to achieve optimal lens adhesion and durability.

- Inspected and calibrated lens cementing equipment to ensure accurate and consistent results.

- Developed and implemented process improvements to enhance efficiency and reduce production time.

Accomplishments

- Improved lens yield by 5% by optimizing cementing process and reducing bubble formation

- Reduced production downtime by 30% through proactive maintenance and equipment upgrades

- Developed and implemented a training program to enhance cementer skills and knowledge

- Collaborated with R&D team to develop new lens cementation techniques, resulting in improved optical performance

- Implemented a quality control system to ensure consistent and highquality lens cementing

Certificates

- Certified Lens Cementer (CLC)

- Optical Society of America (OSA)

- Society of Vacuum Coaters (SVC)

- American National Standards Institute (ANSI)

Languages

- English

- French

- German

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Lens Cementer

Quantify your accomplishments

: Use numbers and metrics to demonstrate the impact of your contributions, such as improving yield by 5% or reducing downtime by 30%.Highlight your technical skills

: Emphasize your proficiency in lens inspection, grinding, polishing, coating, assembly, and optical metrology.Showcase your problem-solving abilities

: Describe how you identified and resolved challenges in the lens cementing process, such as optimizing the cementing process or implementing proactive maintenance measures.Demonstrate your commitment to quality

: Highlight your experience in implementing quality control systems and your attention to detail in ensuring consistent and high-quality lens cementing.

Essential Experience Highlights for a Strong Lens Cementer Resume

- Improved lens yield by 5% by optimizing cementing process and reducing bubble formation, leading to increased production efficiency and reduced material waste

- Reduced production downtime by 30% through proactive maintenance and equipment upgrades, minimizing disruptions and maximizing production output

- Developed and implemented a training program to enhance cementer skills and knowledge, resulting in improved product quality and reduced errors

- Collaborated with R&D team to develop new lens cementation techniques, leading to improved optical performance and customer satisfaction

- Implemented a quality control system to ensure consistent and high-quality lens cementing, ensuring compliance with industry standards and customer requirements

- Supervised a team of lens cementers, providing guidance and support to maintain production targets and quality standards

- Conducted regular inspections and evaluations to identify areas for improvement in the lens cementing process, ensuring continuous optimization

Frequently Asked Questions (FAQ’s) For Lens Cementer

What are the key responsibilities of a Lens Cementer?

Key responsibilities include inspecting, grinding, polishing, coating, and assembling lenses, as well as conducting optical metrology and implementing quality control systems. Lens Cementers may also be responsible for developing training programs and collaborating with R&D teams.

What are the essential skills for a Lens Cementer?

Essential skills include lens inspection, grinding, polishing, coating, assembly, optical metrology, and quality control. Lens Cementers should also have a strong understanding of optical principles and materials.

What are the career prospects for a Lens Cementer?

Lens Cementers can advance to roles such as Quality Control Manager, Production Supervisor, or Lens Design Engineer. With additional education and experience, they may also pursue careers in research and development.

What are the typical working conditions for a Lens Cementer?

Lens Cementers typically work in clean and well-lit manufacturing environments. They may work with small and delicate components, so precision and attention to detail are essential. Some Lens Cementers may also work with hazardous materials, so proper safety precautions must be followed.

What is the average salary for a Lens Cementer?

The average salary for a Lens Cementer can vary depending on experience, location, and company size. According to Salary.com, the median annual salary for Lens Cementers in the United States is around $50,000.

What are the educational requirements for a Lens Cementer?

Lens Cementers typically have an Associate Degree in Optical Engineering or a related field. Some employers may also require experience in lens manufacturing or a related industry.

What certifications are available for Lens Cementers?

Lens Cementers can obtain certifications from organizations such as the Optical Society of America (OSA) and the American National Standards Institute (ANSI). These certifications demonstrate proficiency in lens manufacturing and quality control.