Are you a seasoned Longwall Shearer Operator seeking a new career path? Discover our professionally built Longwall Shearer Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

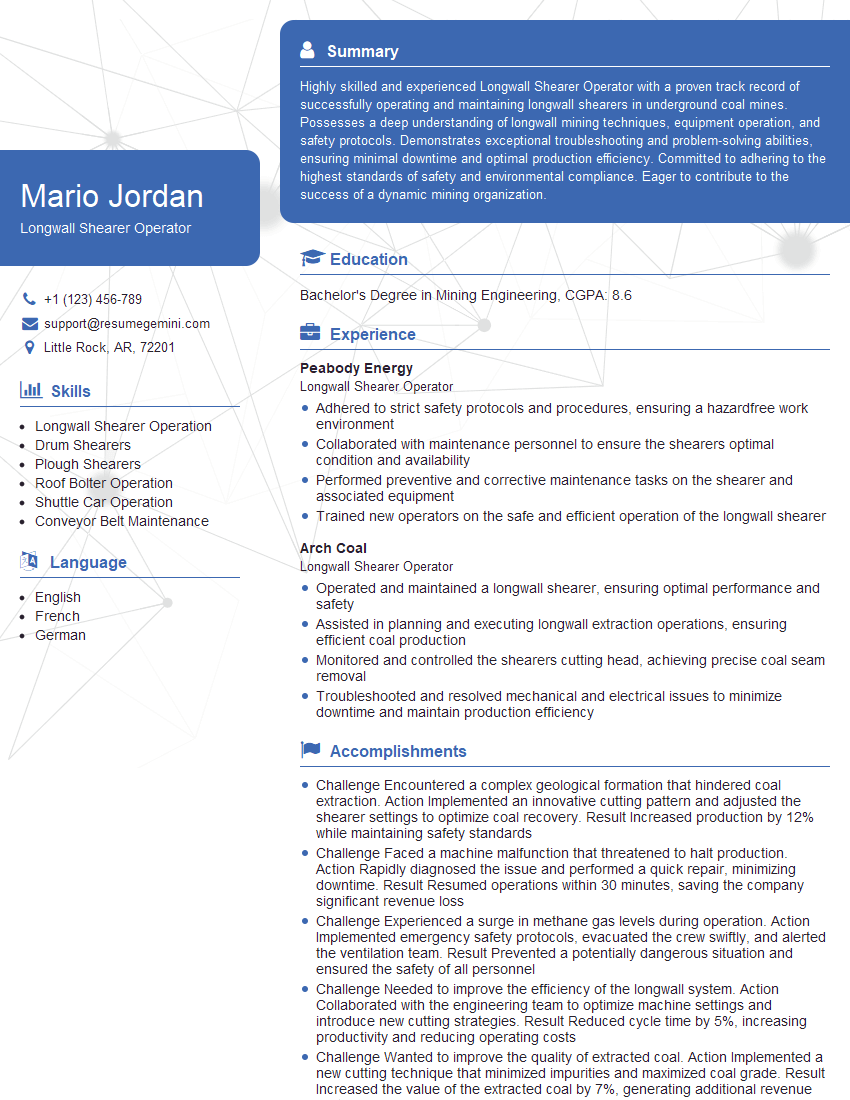

Mario Jordan

Longwall Shearer Operator

Summary

Highly skilled and experienced Longwall Shearer Operator with a proven track record of successfully operating and maintaining longwall shearers in underground coal mines. Possesses a deep understanding of longwall mining techniques, equipment operation, and safety protocols. Demonstrates exceptional troubleshooting and problem-solving abilities, ensuring minimal downtime and optimal production efficiency. Committed to adhering to the highest standards of safety and environmental compliance. Eager to contribute to the success of a dynamic mining organization.

Education

Bachelor’s Degree in Mining Engineering

June 2017

Skills

- Longwall Shearer Operation

- Drum Shearers

- Plough Shearers

- Roof Bolter Operation

- Shuttle Car Operation

- Conveyor Belt Maintenance

Work Experience

Longwall Shearer Operator

- Adhered to strict safety protocols and procedures, ensuring a hazardfree work environment

- Collaborated with maintenance personnel to ensure the shearers optimal condition and availability

- Performed preventive and corrective maintenance tasks on the shearer and associated equipment

- Trained new operators on the safe and efficient operation of the longwall shearer

Longwall Shearer Operator

- Operated and maintained a longwall shearer, ensuring optimal performance and safety

- Assisted in planning and executing longwall extraction operations, ensuring efficient coal production

- Monitored and controlled the shearers cutting head, achieving precise coal seam removal

- Troubleshooted and resolved mechanical and electrical issues to minimize downtime and maintain production efficiency

Accomplishments

- Challenge Encountered a complex geological formation that hindered coal extraction. Action Implemented an innovative cutting pattern and adjusted the shearer settings to optimize coal recovery. Result Increased production by 12% while maintaining safety standards

- Challenge Faced a machine malfunction that threatened to halt production. Action Rapidly diagnosed the issue and performed a quick repair, minimizing downtime. Result Resumed operations within 30 minutes, saving the company significant revenue loss

- Challenge Experienced a surge in methane gas levels during operation. Action Implemented emergency safety protocols, evacuated the crew swiftly, and alerted the ventilation team. Result Prevented a potentially dangerous situation and ensured the safety of all personnel

- Challenge Needed to improve the efficiency of the longwall system. Action Collaborated with the engineering team to optimize machine settings and introduce new cutting strategies. Result Reduced cycle time by 5%, increasing productivity and reducing operating costs

- Challenge Wanted to improve the quality of extracted coal. Action Implemented a new cutting technique that minimized impurities and maximized coal grade. Result Increased the value of the extracted coal by 7%, generating additional revenue for the company

Awards

- Received the National Award for Outstanding Longwall Shearer Operator

- Awarded the Companys Safety Excellence Award for exemplary performance in maintaining a safe work environment

- Recognized with the Presidents Award for exceptional contribution to the teams productivity

- Received the Mine Safety and Health Administration (MSHA) Certificate of Training for Longwall Shearer Operators

Certificates

- Mine Safety and Health Administration (MSHA) Part 48

- MSHA Part 46

- MSHA Part 47

- National Institute for Occupational Safety and Health (NIOSH) Approved Respirable Dust Control

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Longwall Shearer Operator

- Highlight your experience operating and maintaining longwall shearers in underground coal mines.

- Quantify your accomplishments whenever possible, using specific metrics to demonstrate your impact.

- Showcase your troubleshooting and problem-solving abilities, emphasizing how you resolved complex technical issues.

- Emphasize your commitment to safety and environmental compliance, providing examples of how you have contributed to a safe and sustainable work environment.

Essential Experience Highlights for a Strong Longwall Shearer Operator Resume

- Operated and maintained longwall shearers, ensuring optimal performance and safety.

- Assisted in planning and executing longwall extraction operations, ensuring efficient coal production.

- Monitored and controlled the shearers cutting head, achieving precise coal seam removal.

- Troubleshooted and resolved mechanical and electrical issues to minimize downtime and maintain production efficiency.

- Adhered to strict safety protocols and procedures, ensuring a hazard-free work environment.

- Collaborated with maintenance personnel to ensure the shearers optimal condition and availability.

- Performed preventive and corrective maintenance tasks on the shearer and associated equipment.

Frequently Asked Questions (FAQ’s) For Longwall Shearer Operator

What are the key responsibilities of a Longwall Shearer Operator?

The key responsibilities of a Longwall Shearer Operator include operating and maintaining longwall shearers, planning and executing longwall extraction operations, monitoring and controlling the shearers cutting head, troubleshooting and resolving mechanical and electrical issues, adhering to safety protocols and procedures, collaborating with maintenance personnel, and performing preventive and corrective maintenance tasks.

What are the qualifications required to become a Longwall Shearer Operator?

The qualifications required to become a Longwall Shearer Operator typically include a high school diploma or equivalent, experience operating heavy machinery, and knowledge of longwall mining techniques and equipment.

What are the career prospects for a Longwall Shearer Operator?

Longwall Shearer Operators are in high demand in the mining industry, as they play a critical role in the efficient extraction of coal. With experience and training, Longwall Shearer Operators can advance to supervisory or management positions in the mining industry.

What is the average salary for a Longwall Shearer Operator?

The average salary for a Longwall Shearer Operator varies depending on experience, location, and company size. According to the U.S. Bureau of Labor Statistics, the median annual salary for Mining Machine Operators, which includes Longwall Shearer Operators, was $63,240 in May 2022.

What are the challenges faced by Longwall Shearer Operators?

Longwall Shearer Operators face a number of challenges, including working in dangerous and demanding conditions, exposure to hazardous materials, and long and irregular work hours. Additionally, Longwall Shearer Operators must be able to work independently and as part of a team, and they must be able to quickly adapt to changing conditions.

What are the safety precautions that Longwall Shearer Operators must follow?

Longwall Shearer Operators must follow a number of safety precautions to minimize the risk of accidents and injuries. These precautions include wearing appropriate safety gear, following established operating procedures, and adhering to all safety regulations and protocols.

What are the key skills and abilities required for a Longwall Shearer Operator?

The key skills and abilities required for a Longwall Shearer Operator include the ability to operate and maintain heavy machinery, knowledge of longwall mining techniques and equipment, troubleshooting and problem-solving abilities, and adherence to safety protocols and procedures.