Are you a seasoned Lot Technician seeking a new career path? Discover our professionally built Lot Technician Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

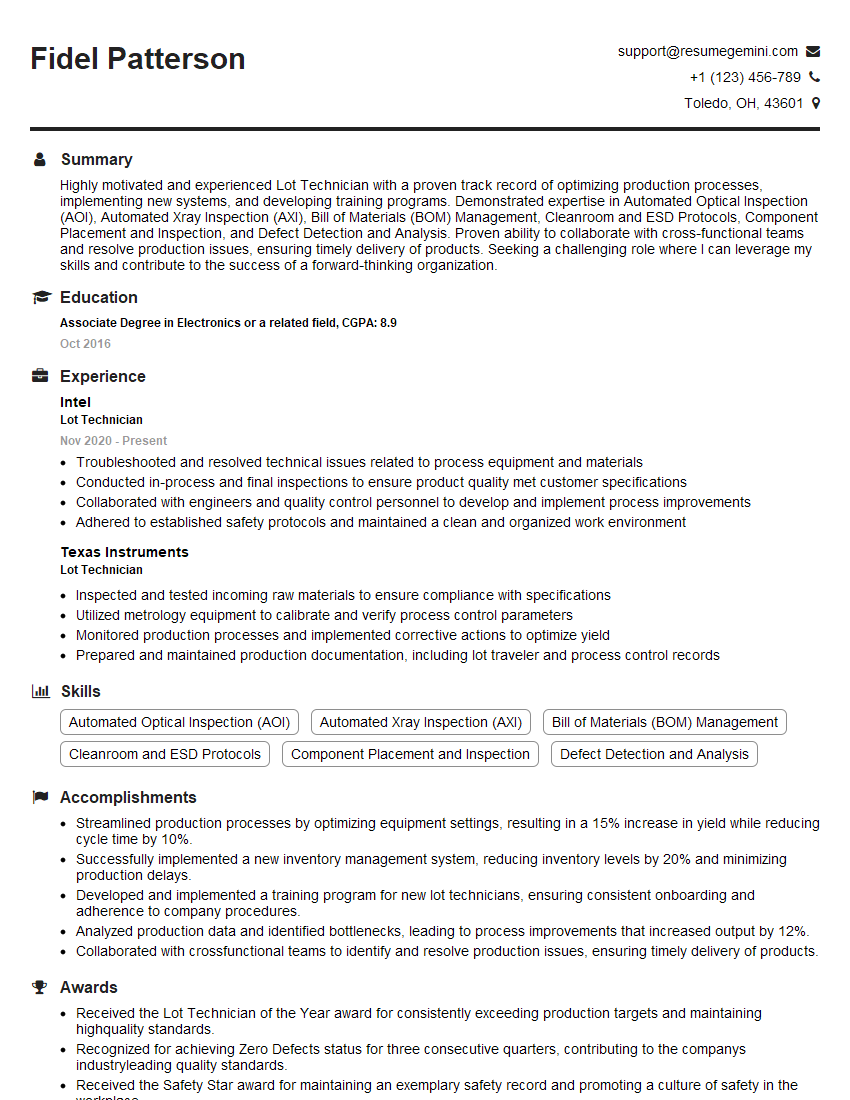

Fidel Patterson

Lot Technician

Summary

Highly motivated and experienced Lot Technician with a proven track record of optimizing production processes, implementing new systems, and developing training programs. Demonstrated expertise in Automated Optical Inspection (AOI), Automated Xray Inspection (AXI), Bill of Materials (BOM) Management, Cleanroom and ESD Protocols, Component Placement and Inspection, and Defect Detection and Analysis. Proven ability to collaborate with cross-functional teams and resolve production issues, ensuring timely delivery of products. Seeking a challenging role where I can leverage my skills and contribute to the success of a forward-thinking organization.

Education

Associate Degree in Electronics or a related field

October 2016

Skills

- Automated Optical Inspection (AOI)

- Automated Xray Inspection (AXI)

- Bill of Materials (BOM) Management

- Cleanroom and ESD Protocols

- Component Placement and Inspection

- Defect Detection and Analysis

Work Experience

Lot Technician

- Troubleshooted and resolved technical issues related to process equipment and materials

- Conducted in-process and final inspections to ensure product quality met customer specifications

- Collaborated with engineers and quality control personnel to develop and implement process improvements

- Adhered to established safety protocols and maintained a clean and organized work environment

Lot Technician

- Inspected and tested incoming raw materials to ensure compliance with specifications

- Utilized metrology equipment to calibrate and verify process control parameters

- Monitored production processes and implemented corrective actions to optimize yield

- Prepared and maintained production documentation, including lot traveler and process control records

Accomplishments

- Streamlined production processes by optimizing equipment settings, resulting in a 15% increase in yield while reducing cycle time by 10%.

- Successfully implemented a new inventory management system, reducing inventory levels by 20% and minimizing production delays.

- Developed and implemented a training program for new lot technicians, ensuring consistent onboarding and adherence to company procedures.

- Analyzed production data and identified bottlenecks, leading to process improvements that increased output by 12%.

- Collaborated with crossfunctional teams to identify and resolve production issues, ensuring timely delivery of products.

Awards

- Received the Lot Technician of the Year award for consistently exceeding production targets and maintaining highquality standards.

- Recognized for achieving Zero Defects status for three consecutive quarters, contributing to the companys industryleading quality standards.

- Received the Safety Star award for maintaining an exemplary safety record and promoting a culture of safety in the workplace.

- Commended for contributing to the companys ISO 9001 certification by implementing quality control measures that met international standards.

Certificates

- ASQ Certified Quality Engineer (CQE)

- Certified IPC Specialist (CIS)

- Certified Manufacturing Technologist (CMfgT)

- Certified Quality Inspector (CQI)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Lot Technician

Quantify your accomplishments:

Use specific metrics and data to demonstrate the impact of your work. For example, instead of saying “Increased yield,” say “Streamlined production processes by optimizing equipment settings, resulting in a 15% increase in yield.”Highlight your skills and experience:

Make sure your resume includes a detailed list of your skills and experience, including any relevant certifications. For example, list “Automated Optical Inspection (AOI), Automated Xray Inspection (AXI), Bill of Materials (BOM) Management, Cleanroom and ESD Protocols, Component Placement and Inspection, and Defect Detection and Analysis.”Tailor your resume to the job:

Carefully review the job description and tailor your resume to match the specific requirements of the role. For example, if the job description mentions “Experience with a specific software program,” make sure to highlight your experience with that software on your resume.Proofread carefully:

Before submitting your resume, proofread it carefully for any errors in grammar, spelling, or punctuation.Get feedback from others:

Ask a friend, family member, or career counselor to review your resume and provide feedback.

Essential Experience Highlights for a Strong Lot Technician Resume

- Streamlined production processes by optimizing equipment settings, resulting in increased yield and reduced cycle time.

- Successfully implemented a new inventory management system, reducing inventory levels and minimizing production delays.

- Developed and implemented a training program for new lot technicians, ensuring consistent onboarding and adherence to company procedures.

- Analyzed production data and identified bottlenecks, leading to process improvements that increased output.

- Collaborated with cross-functional teams to identify and resolve production issues, ensuring timely delivery of products.

- Consistently met or exceeded production targets, while maintaining high levels of quality and accuracy.

- Actively participated in continuous improvement initiatives, suggesting and implementing process enhancements.

- Maintained a clean and organized work area, adhering to all safety and environmental regulations.

Frequently Asked Questions (FAQ’s) For Lot Technician

What is the role of a Lot Technician?

A Lot Technician is responsible for the day-to-day operation and maintenance of production equipment in a manufacturing environment. They work closely with other members of the production team to ensure that products are produced efficiently and meet quality standards.

What skills are required to be a Lot Technician?

Lot Technicians typically need to have a strong understanding of manufacturing processes, as well as experience with a variety of production equipment. They also need to be able to work independently and as part of a team, and be able to follow instructions and procedures carefully.

What is the career outlook for Lot Technicians?

The career outlook for Lot Technicians is expected to be good over the next few years. As manufacturing continues to grow, there will be a need for more qualified technicians to operate and maintain production equipment.

How can I become a Lot Technician?

There are a number of ways to become a Lot Technician. Some people start by working in a manufacturing environment and then move into a technician role. Others may complete a formal training program or earn a degree in a related field.

What is the average salary for a Lot Technician?

The average salary for a Lot Technician varies depending on experience, location, and industry. However, according to the U.S. Bureau of Labor Statistics, the median annual salary for Production Workers is $37,690.

What are the benefits of being a Lot Technician?

There are a number of benefits to being a Lot Technician, including good pay, job security, and the opportunity to work with a variety of people and technologies.

What are the challenges of being a Lot Technician?

There are also some challenges to being a Lot Technician, including working in a fast-paced environment, dealing with repetitive tasks, and working with hazardous materials.