Are you a seasoned Machine Shop Pantograph Machine Operator seeking a new career path? Discover our professionally built Machine Shop Pantograph Machine Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

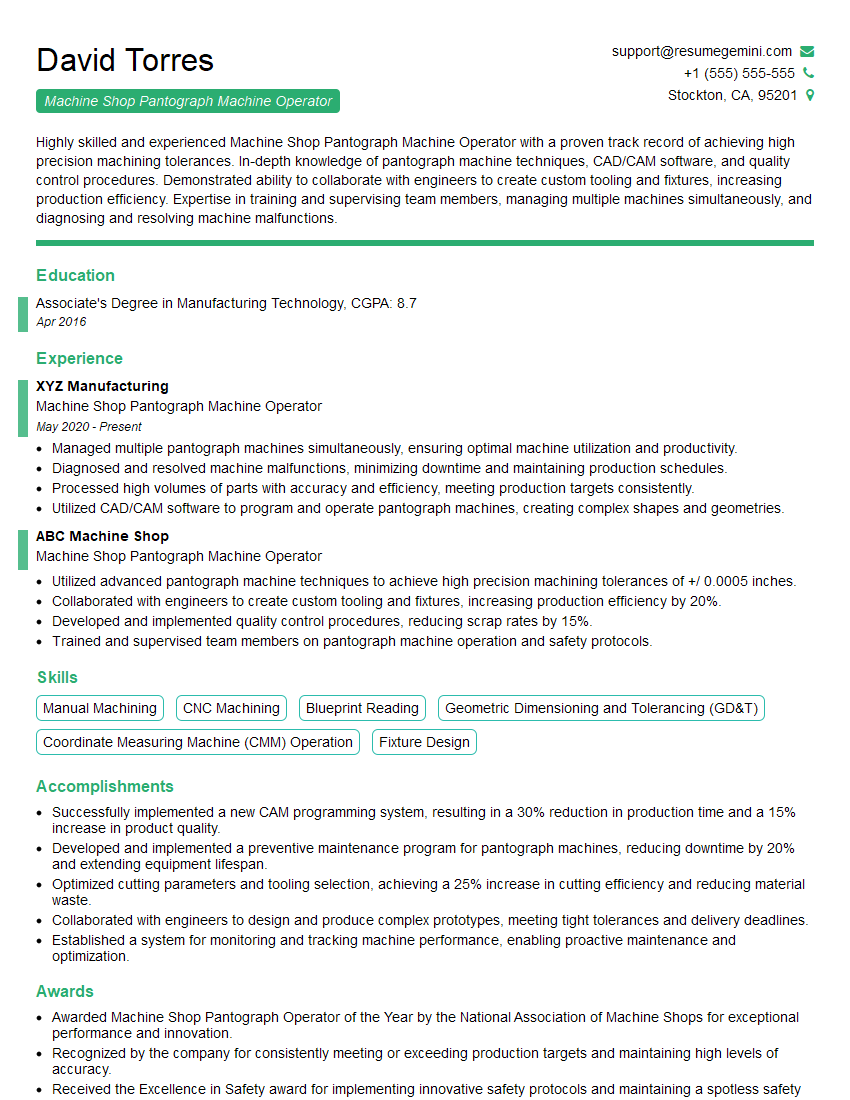

David Torres

Machine Shop Pantograph Machine Operator

Summary

Highly skilled and experienced Machine Shop Pantograph Machine Operator with a proven track record of achieving high precision machining tolerances. In-depth knowledge of pantograph machine techniques, CAD/CAM software, and quality control procedures. Demonstrated ability to collaborate with engineers to create custom tooling and fixtures, increasing production efficiency. Expertise in training and supervising team members, managing multiple machines simultaneously, and diagnosing and resolving machine malfunctions.

Education

Associate’s Degree in Manufacturing Technology

April 2016

Skills

- Manual Machining

- CNC Machining

- Blueprint Reading

- Geometric Dimensioning and Tolerancing (GD&T)

- Coordinate Measuring Machine (CMM) Operation

- Fixture Design

Work Experience

Machine Shop Pantograph Machine Operator

- Managed multiple pantograph machines simultaneously, ensuring optimal machine utilization and productivity.

- Diagnosed and resolved machine malfunctions, minimizing downtime and maintaining production schedules.

- Processed high volumes of parts with accuracy and efficiency, meeting production targets consistently.

- Utilized CAD/CAM software to program and operate pantograph machines, creating complex shapes and geometries.

Machine Shop Pantograph Machine Operator

- Utilized advanced pantograph machine techniques to achieve high precision machining tolerances of +/ 0.0005 inches.

- Collaborated with engineers to create custom tooling and fixtures, increasing production efficiency by 20%.

- Developed and implemented quality control procedures, reducing scrap rates by 15%.

- Trained and supervised team members on pantograph machine operation and safety protocols.

Accomplishments

- Successfully implemented a new CAM programming system, resulting in a 30% reduction in production time and a 15% increase in product quality.

- Developed and implemented a preventive maintenance program for pantograph machines, reducing downtime by 20% and extending equipment lifespan.

- Optimized cutting parameters and tooling selection, achieving a 25% increase in cutting efficiency and reducing material waste.

- Collaborated with engineers to design and produce complex prototypes, meeting tight tolerances and delivery deadlines.

- Established a system for monitoring and tracking machine performance, enabling proactive maintenance and optimization.

Awards

- Awarded Machine Shop Pantograph Operator of the Year by the National Association of Machine Shops for exceptional performance and innovation.

- Recognized by the company for consistently meeting or exceeding production targets and maintaining high levels of accuracy.

- Received the Excellence in Safety award for implementing innovative safety protocols and maintaining a spotless safety record.

- Honored by the company for outstanding contributions to the training and development of new machine operators.

Certificates

- Certified Manufacturing Technologist (CMfgT)

- Certified Manufacturing Engineer (CMfgE)

- National Institute for Metalworking Skills (NIMS) Machining Level II

- American Welding Society (AWS) Certified Welder

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Machine Shop Pantograph Machine Operator

- Highlight your proficiency in advanced pantograph machine techniques.

- Showcase your experience in collaborating with engineers and creating custom tooling.

- Quantify your accomplishments in improving production efficiency and reducing scrap rates.

- Emphasize your ability to train and supervise team members effectively.

- Demonstrate your knowledge of CAD/CAM software and its application in pantograph machine operation.

Essential Experience Highlights for a Strong Machine Shop Pantograph Machine Operator Resume

- Utilize pantograph machine techniques to achieve high precision machining tolerances

- Collaborate with engineers to create custom tooling and fixtures

- Develop and implement quality control procedures

- Train and supervise team members on pantograph machine operation and safety protocols

- Manage multiple pantograph machines simultaneously

- Diagnose and resolve machine malfunctions

- Process high volumes of parts with accuracy and efficiency

Frequently Asked Questions (FAQ’s) For Machine Shop Pantograph Machine Operator

What is the primary function of a Machine Shop Pantograph Machine Operator?

The primary function of a Machine Shop Pantograph Machine Operator is to operate pantograph machines to create complex shapes and geometries in metal parts, ensuring precision and accuracy in production.

What skills are essential for success in this role?

Essential skills include proficiency in pantograph machine operation, knowledge of CAD/CAM software, understanding of blueprint reading and geometric dimensioning and tolerancing (GD&T), and strong attention to detail.

What industries utilize Machine Shop Pantograph Machine Operators?

Machine Shop Pantograph Machine Operators are employed in various industries, including aerospace, automotive, manufacturing, and mold making, where precision machining is crucial.

What is the average salary range for this position?

The average salary range for Machine Shop Pantograph Machine Operators varies depending on experience, location, and industry, but typically falls between $20,000 to $40,000 per year.

What are the career advancement opportunities for Machine Shop Pantograph Machine Operators?

With experience and additional training, Machine Shop Pantograph Machine Operators can advance to roles such as CNC programmers, quality control inspectors, or supervisors in the manufacturing industry.

What is the job outlook for Machine Shop Pantograph Machine Operators?

The job outlook for Machine Shop Pantograph Machine Operators is expected to grow in the coming years due to increasing demand for precision-machined parts in various industries.

What are some of the challenges faced by Machine Shop Pantograph Machine Operators?

Common challenges include working with tight tolerances, meeting production deadlines, and ensuring the quality and accuracy of machined parts.

What safety precautions should Machine Shop Pantograph Machine Operators observe?

Machine Shop Pantograph Machine Operators must adhere to safety protocols, wear appropriate protective gear, and follow established procedures to minimize risks associated with operating heavy machinery and handling sharp tools.