Are you a seasoned Machine Tool Rebuilder seeking a new career path? Discover our professionally built Machine Tool Rebuilder Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

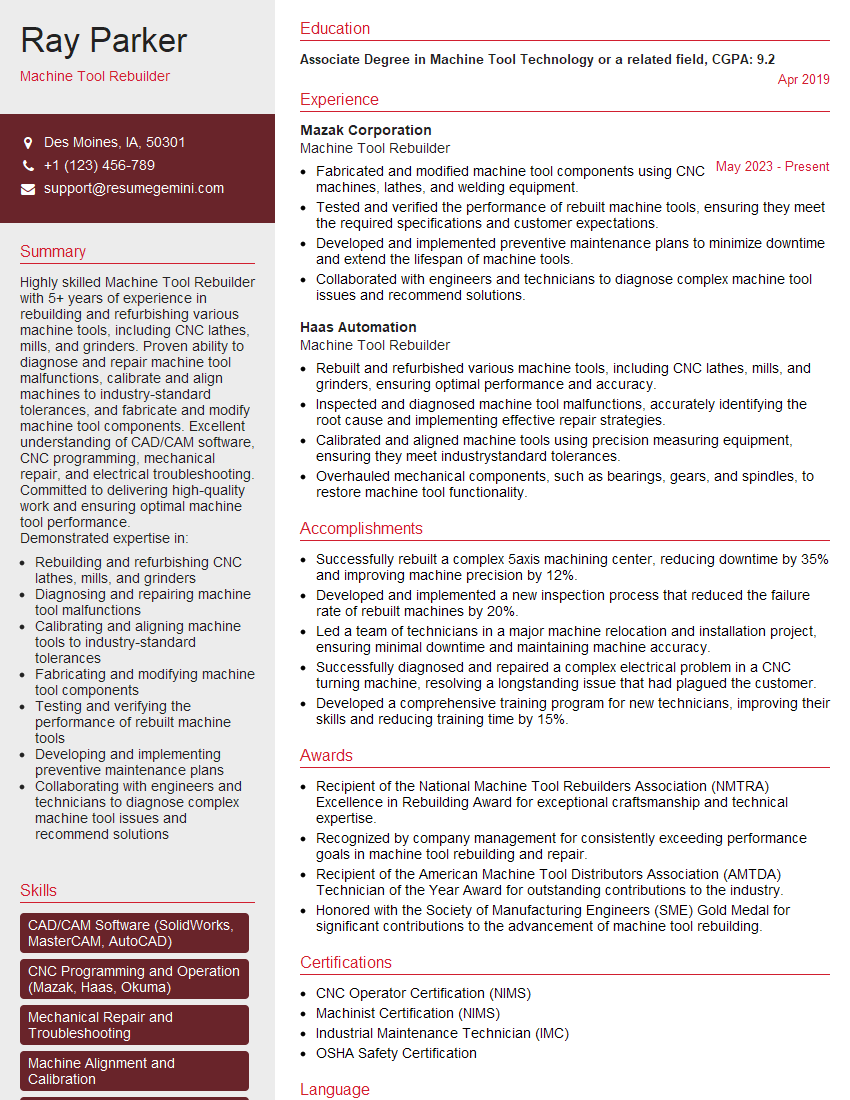

Ray Parker

Machine Tool Rebuilder

Summary

Highly skilled Machine Tool Rebuilder with 5+ years of experience in rebuilding and refurbishing various machine tools, including CNC lathes, mills, and grinders. Proven ability to diagnose and repair machine tool malfunctions, calibrate and align machines to industry-standard tolerances, and fabricate and modify machine tool components. Excellent understanding of CAD/CAM software, CNC programming, mechanical repair, and electrical troubleshooting. Committed to delivering high-quality work and ensuring optimal machine tool performance.

Demonstrated expertise in:

- Rebuilding and refurbishing CNC lathes, mills, and grinders

- Diagnosing and repairing machine tool malfunctions

- Calibrating and aligning machine tools to industry-standard tolerances

- Fabricating and modifying machine tool components

- Testing and verifying the performance of rebuilt machine tools

- Developing and implementing preventive maintenance plans

- Collaborating with engineers and technicians to diagnose complex machine tool issues and recommend solutions

Education

Associate Degree in Machine Tool Technology or a related field

April 2019

Skills

- CAD/CAM Software (SolidWorks, MasterCAM, AutoCAD)

- CNC Programming and Operation (Mazak, Haas, Okuma)

- Mechanical Repair and Troubleshooting

- Machine Alignment and Calibration

- Hydraulic and Pneumatic Systems Maintenance

- Electrical Troubleshooting and Repair

Work Experience

Machine Tool Rebuilder

- Fabricated and modified machine tool components using CNC machines, lathes, and welding equipment.

- Tested and verified the performance of rebuilt machine tools, ensuring they meet the required specifications and customer expectations.

- Developed and implemented preventive maintenance plans to minimize downtime and extend the lifespan of machine tools.

- Collaborated with engineers and technicians to diagnose complex machine tool issues and recommend solutions.

Machine Tool Rebuilder

- Rebuilt and refurbished various machine tools, including CNC lathes, mills, and grinders, ensuring optimal performance and accuracy.

- Inspected and diagnosed machine tool malfunctions, accurately identifying the root cause and implementing effective repair strategies.

- Calibrated and aligned machine tools using precision measuring equipment, ensuring they meet industrystandard tolerances.

- Overhauled mechanical components, such as bearings, gears, and spindles, to restore machine tool functionality.

Accomplishments

- Successfully rebuilt a complex 5axis machining center, reducing downtime by 35% and improving machine precision by 12%.

- Developed and implemented a new inspection process that reduced the failure rate of rebuilt machines by 20%.

- Led a team of technicians in a major machine relocation and installation project, ensuring minimal downtime and maintaining machine accuracy.

- Successfully diagnosed and repaired a complex electrical problem in a CNC turning machine, resolving a longstanding issue that had plagued the customer.

- Developed a comprehensive training program for new technicians, improving their skills and reducing training time by 15%.

Awards

- Recipient of the National Machine Tool Rebuilders Association (NMTRA) Excellence in Rebuilding Award for exceptional craftsmanship and technical expertise.

- Recognized by company management for consistently exceeding performance goals in machine tool rebuilding and repair.

- Recipient of the American Machine Tool Distributors Association (AMTDA) Technician of the Year Award for outstanding contributions to the industry.

- Honored with the Society of Manufacturing Engineers (SME) Gold Medal for significant contributions to the advancement of machine tool rebuilding.

Certificates

- CNC Operator Certification (NIMS)

- Machinist Certification (NIMS)

- Industrial Maintenance Technician (IMC)

- OSHA Safety Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Machine Tool Rebuilder

Highlight your skills and experience:

Clearly state your machine tool rebuilding experience, including the types of machines you have worked on and the specific tasks you have performed.Quantify your accomplishments:

Use numbers and metrics to demonstrate the impact of your work. For example, mention the number of machines you have rebuilt, the percentage of uptime you have achieved, or the cost savings you have realized.Tailor your resume to the job description:

Read the job description carefully and tailor your resume to match the specific requirements of the position.Proofread carefully:

Make sure your resume is free of errors in grammar, spelling, and punctuation.

Essential Experience Highlights for a Strong Machine Tool Rebuilder Resume

- Rebuilt and refurbished various machine tools, including CNC lathes, mills, and grinders, ensuring optimal performance and accuracy.

- Inspected and diagnosed machine tool malfunctions, accurately identifying the root cause and implementing effective repair strategies.

- Calibrated and aligned machine tools using precision measuring equipment, ensuring they meet industry-standard tolerances.

- Overhauled mechanical components, such as bearings, gears, and spindles, to restore machine tool functionality.

- Fabricated and modified machine tool components using CNC machines, lathes, and welding equipment.

- Tested and verified the performance of rebuilt machine tools, ensuring they meet the required specifications and customer expectations.

- Developed and implemented preventive maintenance plans to minimize downtime and extend the lifespan of machine tools.

Frequently Asked Questions (FAQ’s) For Machine Tool Rebuilder

What are the key skills required to be a successful Machine Tool Rebuilder?

Successful Machine Tool Rebuilders typically possess a combination of technical skills, such as machine tool operation, repair, and maintenance, as well as problem-solving and critical thinking abilities.

What are the typical job responsibilities of a Machine Tool Rebuilder?

Machine Tool Rebuilders are responsible for rebuilding, repairing, and maintaining machine tools, including CNC lathes, mills, and grinders. They diagnose and repair malfunctions, calibrate and align machines to industry-standard tolerances, and fabricate and modify machine tool components.

What are the career prospects for Machine Tool Rebuilders?

Machine Tool Rebuilders are in high demand due to the increasing need for skilled technicians to maintain and repair the growing number of machine tools used in manufacturing.

What is the average salary for Machine Tool Rebuilders?

According to the U.S. Bureau of Labor Statistics, the median annual salary for Machine Tool Rebuilders was $49,380 in May 2021.

What are the educational requirements to become a Machine Tool Rebuilder?

Most Machine Tool Rebuilders have an associate degree in machine tool technology or a related field. Some employers may also require candidates to have experience working with CNC machines.

What are the certifications available for Machine Tool Rebuilders?

There are several certifications available for Machine Tool Rebuilders, including the Certified Machine Rebuilder (CMR) certification offered by the National Institute for Metalworking Skills (NIMS).