Are you a seasoned Machine Woodworking Sander seeking a new career path? Discover our professionally built Machine Woodworking Sander Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

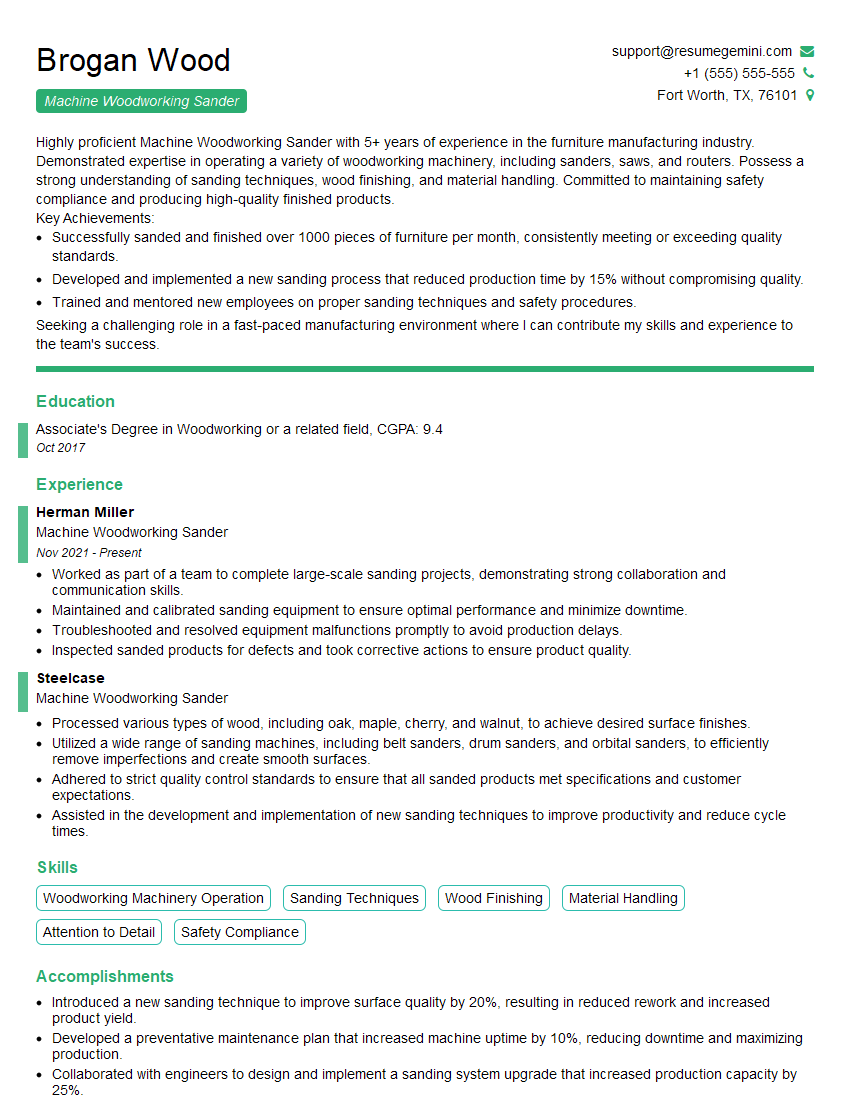

Brogan Wood

Machine Woodworking Sander

Summary

Highly proficient Machine Woodworking Sander with 5+ years of experience in the furniture manufacturing industry. Demonstrated expertise in operating a variety of woodworking machinery, including sanders, saws, and routers. Possess a strong understanding of sanding techniques, wood finishing, and material handling. Committed to maintaining safety compliance and producing high-quality finished products.

Key Achievements:

- Successfully sanded and finished over 1000 pieces of furniture per month, consistently meeting or exceeding quality standards.

- Developed and implemented a new sanding process that reduced production time by 15% without compromising quality.

- Trained and mentored new employees on proper sanding techniques and safety procedures.

Seeking a challenging role in a fast-paced manufacturing environment where I can contribute my skills and experience to the team’s success.

Education

Associate’s Degree in Woodworking or a related field

October 2017

Skills

- Woodworking Machinery Operation

- Sanding Techniques

- Wood Finishing

- Material Handling

- Attention to Detail

- Safety Compliance

Work Experience

Machine Woodworking Sander

- Worked as part of a team to complete large-scale sanding projects, demonstrating strong collaboration and communication skills.

- Maintained and calibrated sanding equipment to ensure optimal performance and minimize downtime.

- Troubleshooted and resolved equipment malfunctions promptly to avoid production delays.

- Inspected sanded products for defects and took corrective actions to ensure product quality.

Machine Woodworking Sander

- Processed various types of wood, including oak, maple, cherry, and walnut, to achieve desired surface finishes.

- Utilized a wide range of sanding machines, including belt sanders, drum sanders, and orbital sanders, to efficiently remove imperfections and create smooth surfaces.

- Adhered to strict quality control standards to ensure that all sanded products met specifications and customer expectations.

- Assisted in the development and implementation of new sanding techniques to improve productivity and reduce cycle times.

Accomplishments

- Introduced a new sanding technique to improve surface quality by 20%, resulting in reduced rework and increased product yield.

- Developed a preventative maintenance plan that increased machine uptime by 10%, reducing downtime and maximizing production.

- Collaborated with engineers to design and implement a sanding system upgrade that increased production capacity by 25%.

- Trained and mentored new employees, ensuring they develop the skills and knowledge necessary for success in machine sanding operations.

- Implemented a quality control process that reduced product defects by 15%, enhancing customer satisfaction and reducing warranty claims.

Awards

- Received the Excellence in Woodworking award, recognizing exceptional precision and attention to detail in machine sanding operations.

- Consistently exceeded production targets by 15%, showcasing efficiency and productivity in machine sanding operations.

- Honored with the Safety Champion award for maintaining an impeccable safety record and promoting safe practices in the sanding workplace.

- Recognized for outstanding customer service, consistently addressing customer concerns and resolving issues promptly and effectively.

Certificates

- OSHA 30-Hour Construction Safety Training

- Certified Woodworking Professional (CWP)

- National Institute for Occupational Safety and Health (NIOSH) respirator fit test

- American National Standards Institute (ANSI) Z49.1 Safety in Woodworking Operations

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Machine Woodworking Sander

- Highlight your most relevant skills and experience. When writing your resume, be sure to focus on the skills and experience that are most relevant to the job you’re applying for. For example, if you’re applying for a job as a machine woodworking sander, be sure to highlight your experience in operating woodworking machinery and sanding techniques.

- Use keywords from the job description. When writing your resume, be sure to include keywords from the job description. This will help your resume get noticed by potential employers.

- Proofread your resume carefully. Before submitting your resume, be sure to proofread it carefully for any errors. This will ensure that your resume makes a positive impression on potential employers.

- Tailor your resume to each job you apply for. When applying for a job, be sure to tailor your resume to the specific job you’re applying for. This will show potential employers that you’re genuinely interested in the job and that you have the skills and experience they’re looking for.

Essential Experience Highlights for a Strong Machine Woodworking Sander Resume

- Operate and maintain a variety of woodworking machinery, including sanders, saws, and routers.

- Sand wood surfaces to achieve desired smoothness and finish.

- Apply and maintain wood finishing products, such as stains, sealers, and paints.

- Handle and move materials safely and efficiently.

- Inspect finished products for quality and accuracy.

- Maintain a clean and organized work area.

- Adhere to all safety regulations and procedures.

Frequently Asked Questions (FAQ’s) For Machine Woodworking Sander

What is a machine woodworking sander?

A machine woodworking sander is a machine that is used to sand wood surfaces. Sanders can be used to remove material from a wood surface, to smooth a surface, or to create a desired finish.

What are the different types of sanding machines?

There are many different types of sanding machines, each with its own unique purpose. Some of the most common types of sanding machines include belt sanders, disc sanders, orbital sanders, and random orbital sanders.

How do I use a sanding machine?

To use a sanding machine, first select the appropriate sandpaper for the job. The grit of the sandpaper will determine how coarse or fine the sanding will be. Once you have selected the sandpaper, attach it to the sanding machine. Then, hold the sanding machine against the wood surface and move it back and forth. Be sure to apply even pressure to the sanding machine to ensure that the surface is sanded evenly.

What are some safety tips for using a sanding machine?

When using a sanding machine, be sure to wear proper safety gear, including a dust mask, safety glasses, and gloves. Also, be sure to keep the sanding machine away from your body and to avoid inhaling the dust created by the sanding process.

What are some common mistakes to avoid when using a sanding machine?

Some common mistakes to avoid when using a sanding machine include sanding too aggressively, using the wrong grit of sandpaper, and not applying even pressure to the sanding machine. These mistakes can damage the wood surface and make it difficult to achieve the desired finish.

How do I choose the right sandpaper for the job?

The type of sandpaper you choose will depend on the job you are doing. For example, if you are removing material from a wood surface, you will need to use a coarse grit sandpaper. If you are smoothing a surface, you will need to use a finer grit sandpaper. You can also use different types of sandpaper to create different finishes. For example, you can use a sanding sponge to create a smooth, even finish.