Are you a seasoned Machinist Class B seeking a new career path? Discover our professionally built Machinist Class B Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

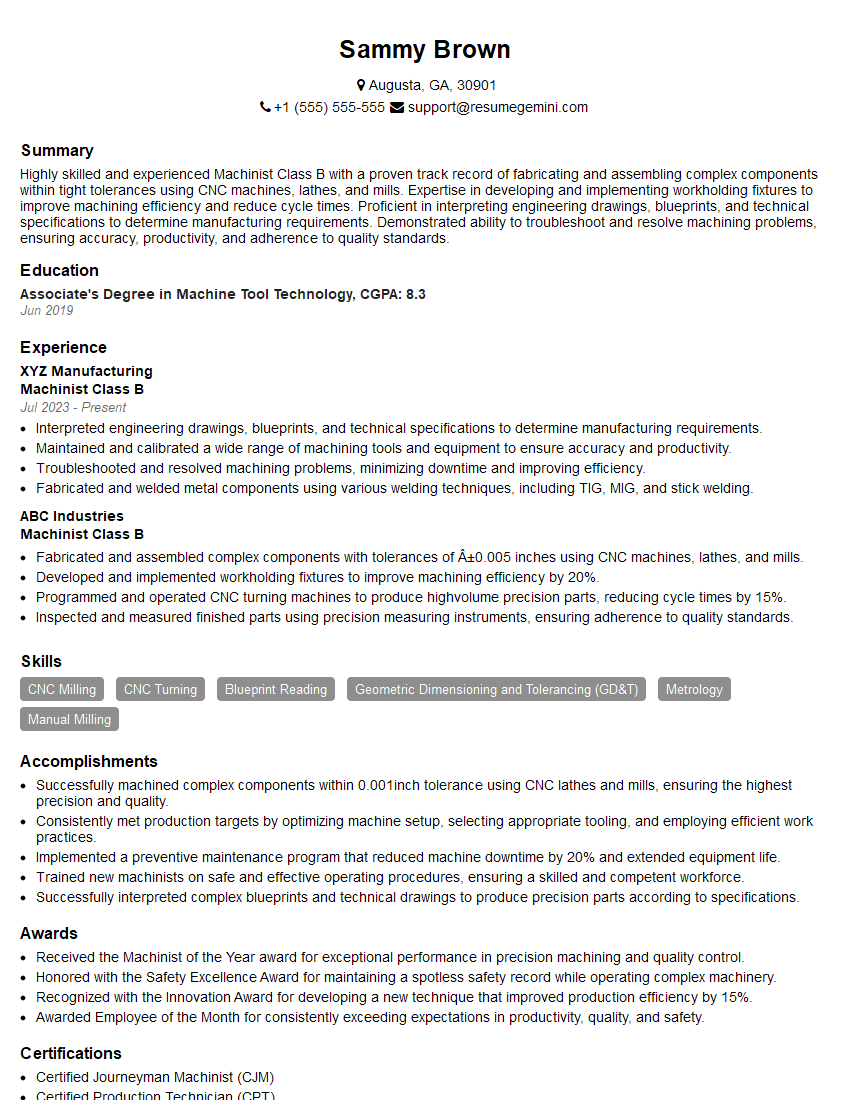

Sammy Brown

Machinist Class B

Summary

Highly skilled and experienced Machinist Class B with a proven track record of fabricating and assembling complex components within tight tolerances using CNC machines, lathes, and mills. Expertise in developing and implementing workholding fixtures to improve machining efficiency and reduce cycle times. Proficient in interpreting engineering drawings, blueprints, and technical specifications to determine manufacturing requirements. Demonstrated ability to troubleshoot and resolve machining problems, ensuring accuracy, productivity, and adherence to quality standards.

Education

Associate’s Degree in Machine Tool Technology

June 2019

Skills

- CNC Milling

- CNC Turning

- Blueprint Reading

- Geometric Dimensioning and Tolerancing (GD&T)

- Metrology

- Manual Milling

Work Experience

Machinist Class B

- Interpreted engineering drawings, blueprints, and technical specifications to determine manufacturing requirements.

- Maintained and calibrated a wide range of machining tools and equipment to ensure accuracy and productivity.

- Troubleshooted and resolved machining problems, minimizing downtime and improving efficiency.

- Fabricated and welded metal components using various welding techniques, including TIG, MIG, and stick welding.

Machinist Class B

- Fabricated and assembled complex components with tolerances of ±0.005 inches using CNC machines, lathes, and mills.

- Developed and implemented workholding fixtures to improve machining efficiency by 20%.

- Programmed and operated CNC turning machines to produce highvolume precision parts, reducing cycle times by 15%.

- Inspected and measured finished parts using precision measuring instruments, ensuring adherence to quality standards.

Accomplishments

- Successfully machined complex components within 0.001inch tolerance using CNC lathes and mills, ensuring the highest precision and quality.

- Consistently met production targets by optimizing machine setup, selecting appropriate tooling, and employing efficient work practices.

- Implemented a preventive maintenance program that reduced machine downtime by 20% and extended equipment life.

- Trained new machinists on safe and effective operating procedures, ensuring a skilled and competent workforce.

- Successfully interpreted complex blueprints and technical drawings to produce precision parts according to specifications.

Awards

- Received the Machinist of the Year award for exceptional performance in precision machining and quality control.

- Honored with the Safety Excellence Award for maintaining a spotless safety record while operating complex machinery.

- Recognized with the Innovation Award for developing a new technique that improved production efficiency by 15%.

- Awarded Employee of the Month for consistently exceeding expectations in productivity, quality, and safety.

Certificates

- Certified Journeyman Machinist (CJM)

- Certified Production Technician (CPT)

- Certified Quality Inspector (CQI)

- Certified Manufacturing Engineer (CMfgE)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Machinist Class B

- Highlight your experience in fabricating and assembling complex components within tight tolerances.

- Showcase your expertise in using CNC machines, lathes, and mills.

- Quantify your accomplishments by providing specific examples of how you improved machining efficiency and reduced cycle times.

- Demonstrate your proficiency in interpreting engineering drawings and technical specifications.

- Emphasize your ability to troubleshoot and resolve machining problems.

Essential Experience Highlights for a Strong Machinist Class B Resume

- Fabricate and assemble complex components with tolerances of ±0.005 inches using CNC machines, lathes, and mills.

- Develop and implement workholding fixtures to improve machining efficiency.

- Inspect and measure finished parts using precision measuring instruments.

- Interpret engineering drawings, blueprints, and technical specifications to determine manufacturing requirements.

- Maintain and calibrate a wide range of machining tools and equipment.

- Troubleshoot and resolve machining problems.

- Fabricate and weld metal components using various welding techniques.

Frequently Asked Questions (FAQ’s) For Machinist Class B

What are the key skills and responsibilities of a Machinist Class B?

Machinist Class B are responsible for fabricating and assembling complex components using CNC machines, lathes, and mills. They must have a strong understanding of blueprint reading, geometric dimensioning and tolerancing (GD&T), and metrology. They must also be able to troubleshoot and resolve machining problems.

What are the educational requirements for a Machinist Class B?

Most Machinist Class B have an Associate’s Degree in Machine Tool Technology or a related field. However, some may have learned the trade through an apprenticeship program.

What are the career prospects for a Machinist Class B?

Machinist Class B can advance to positions such as Machinist Class A, Manufacturing Engineer, or Quality Control Inspector. They may also start their own businesses.

What is the average salary for a Machinist Class B?

The average salary for a Machinist Class B is $25 per hour, according to the Bureau of Labor Statistics.

What are the job opportunities for a Machinist Class B?

Machinist Class B are employed in a variety of industries, including automotive, aerospace, and medical. They may work in machine shops, manufacturing plants, or research and development facilities.

How can I become a Machinist Class B?

You can become a Machinist Class B by completing an Associate’s Degree in Machine Tool Technology or by completing an apprenticeship program.

What is the work environment of a Machinist Class B?

Machinist Class B typically work in machine shops or manufacturing plants. They may be exposed to noise, dust, and fumes. They must also be able to stand for long periods of time and lift heavy objects.

What are the benefits of becoming a Machinist Class B?

Machinist Class B can enjoy a stable career with good pay and benefits. They also have the opportunity to learn new skills and advance their careers.