Are you a seasoned Machinist-Set-Up seeking a new career path? Discover our professionally built Machinist-Set-Up Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

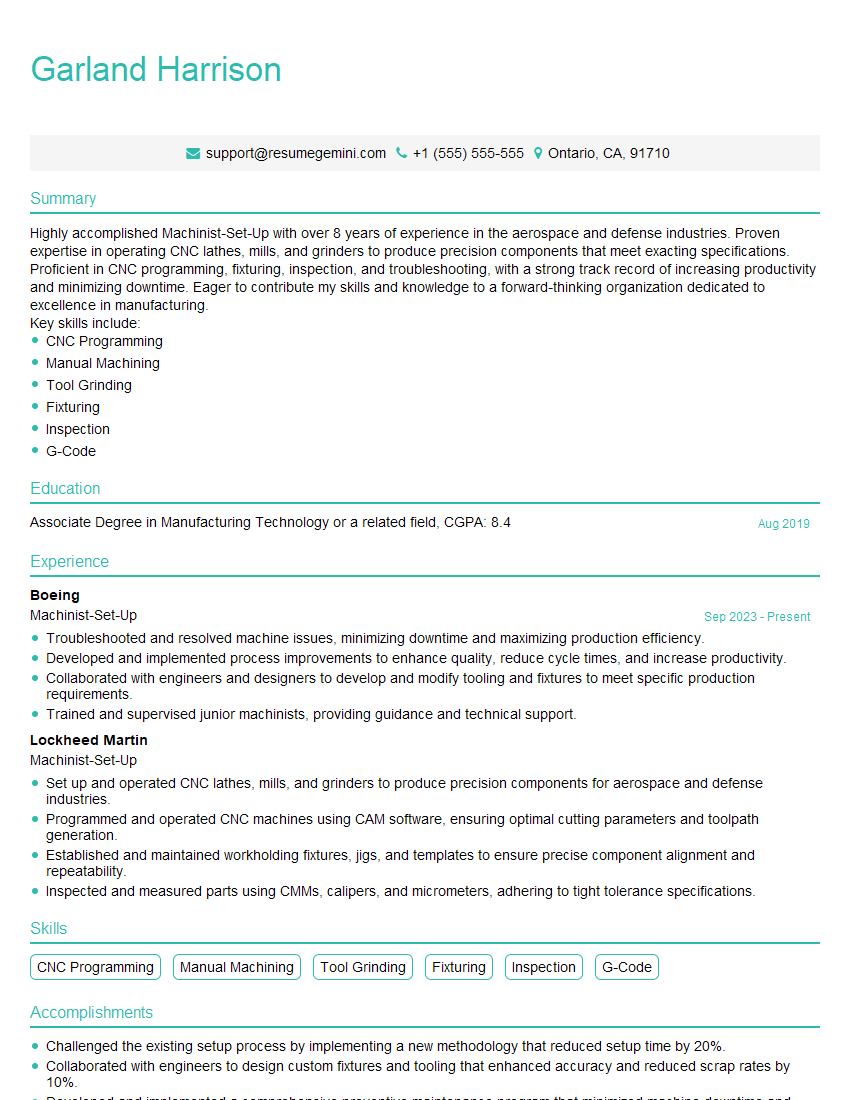

Garland Harrison

Machinist-Set-Up

Summary

Highly accomplished Machinist-Set-Up with over 8 years of experience in the aerospace and defense industries. Proven expertise in operating CNC lathes, mills, and grinders to produce precision components that meet exacting specifications. Proficient in CNC programming, fixturing, inspection, and troubleshooting, with a strong track record of increasing productivity and minimizing downtime. Eager to contribute my skills and knowledge to a forward-thinking organization dedicated to excellence in manufacturing.

Key skills include:

- CNC Programming

- Manual Machining

- Tool Grinding

- Fixturing

- Inspection

- G-Code

Education

Associate Degree in Manufacturing Technology or a related field

August 2019

Skills

- CNC Programming

- Manual Machining

- Tool Grinding

- Fixturing

- Inspection

- G-Code

Work Experience

Machinist-Set-Up

- Troubleshooted and resolved machine issues, minimizing downtime and maximizing production efficiency.

- Developed and implemented process improvements to enhance quality, reduce cycle times, and increase productivity.

- Collaborated with engineers and designers to develop and modify tooling and fixtures to meet specific production requirements.

- Trained and supervised junior machinists, providing guidance and technical support.

Machinist-Set-Up

- Set up and operated CNC lathes, mills, and grinders to produce precision components for aerospace and defense industries.

- Programmed and operated CNC machines using CAM software, ensuring optimal cutting parameters and toolpath generation.

- Established and maintained workholding fixtures, jigs, and templates to ensure precise component alignment and repeatability.

- Inspected and measured parts using CMMs, calipers, and micrometers, adhering to tight tolerance specifications.

Accomplishments

- Challenged the existing setup process by implementing a new methodology that reduced setup time by 20%.

- Collaborated with engineers to design custom fixtures and tooling that enhanced accuracy and reduced scrap rates by 10%.

- Developed and implemented a comprehensive preventive maintenance program that minimized machine downtime and extended the life of critical equipment.

- Successfully implemented a production line reconfiguration that enabled faster changeovers and increased production capacity by 12%.

- Trained and mentored junior machinists, fostering their professional growth and ensuring a skilled workforce for the future.

Awards

- Recognized for exceptional setup and optimization skills, resulting in a 15% increase in production efficiency.

- Received the Machinist of the Month award for consistently exceeding performance targets and maintaining exceptional quality standards.

- Awarded the Safety Champion recognition for implementing innovative safety measures that improved the overall safety record of the department.

- Honored with the Excellence in Innovation award for creating a novel setup technique that revolutionized production processes.

Certificates

- Certified Machinist (CM)

- Master Machinist (MM)

- ISO 9001

- ASME B16.5

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Machinist-Set-Up

- Highlight your experience with specific CNC machines and software, such as CNC lathes, mills, and CAM software.

- Quantify your accomplishments whenever possible. For example, instead of saying “troubleshooted machine issues,” say “troubleshooted machine issues, reducing downtime by 15%”.

- Showcase your understanding of the aerospace and defense industries and their specific manufacturing requirements.

- Emphasize your ability to work independently and as part of a team, as well as your commitment to quality and precision.

Essential Experience Highlights for a Strong Machinist-Set-Up Resume

- Set up and operate CNC lathes, mills, and grinders to produce precision components for aerospace and defense industries.

- Program and operate CNC machines using CAM software, ensuring optimal cutting parameters and toolpath generation.

- Establish and maintain workholding fixtures, jigs, and templates to ensure precise component alignment and repeatability.

- Inspect and measure parts using CMMs, calipers, and micrometers, adhering to tight tolerance specifications.

- Troubleshoot and resolve machine issues, minimizing downtime and maximizing production efficiency.

- Developed and implemented process improvements to enhance quality, reduce cycle times, and increase productivity.

- Collaborated with engineers and designers to develop and modify tooling and fixtures to meet specific production requirements.

Frequently Asked Questions (FAQ’s) For Machinist-Set-Up

What are the key responsibilities of a Machinist-Set-Up?

The key responsibilities of a Machinist-Set-Up include setting up and operating CNC machines, programming and operating CNC machines using CAM software, establishing and maintaining workholding fixtures, jigs, and templates, inspecting and measuring parts, troubleshooting and resolving machine issues, developing and implementing process improvements, and collaborating with engineers and designers.

What are the qualifications for becoming a Machinist-Set-Up?

The qualifications for becoming a Machinist-Set-Up typically include an associate degree in manufacturing technology or a related field, as well as experience with CNC machines, CAM software, and inspection equipment.

What are the career prospects for a Machinist-Set-Up?

The career prospects for a Machinist-Set-Up are good, with a projected growth rate of 10% over the next decade. This growth is due to the increasing demand for precision-machined components in a variety of industries, including aerospace, defense, and medical.

What are the key skills required for a Machinist-Set-Up?

The key skills required for a Machinist-Set-Up include CNC programming, manual machining, tool grinding, fixturing, inspection, and G-code.

What is the work environment of a Machinist-Set-Up?

Machinist-Set-Ups typically work in a machine shop environment, which can be noisy and oily. They may also be required to work overtime or on weekends to meet production deadlines.

What is the salary range for a Machinist-Set-Up?

The salary range for a Machinist-Set-Up can vary depending on experience, location, and company size. According to Indeed, the average salary for a Machinist-Set-Up in the United States is $26.22 per hour.

What are the benefits of working as a Machinist-Set-Up?

The benefits of working as a Machinist-Set-Up can include a competitive salary, health insurance, paid time off, and a retirement plan.