Are you a seasoned Mat Repairer seeking a new career path? Discover our professionally built Mat Repairer Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

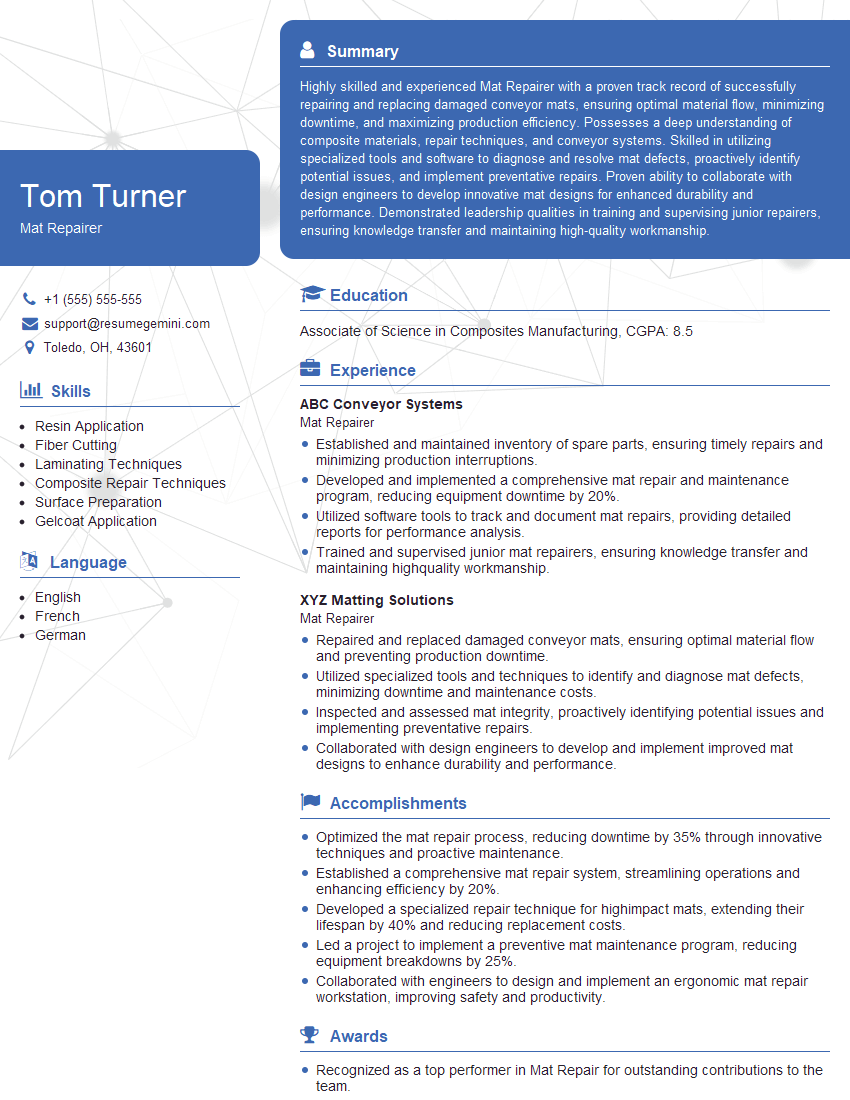

Tom Turner

Mat Repairer

Summary

Highly skilled and experienced Mat Repairer with a proven track record of successfully repairing and replacing damaged conveyor mats, ensuring optimal material flow, minimizing downtime, and maximizing production efficiency. Possesses a deep understanding of composite materials, repair techniques, and conveyor systems. Skilled in utilizing specialized tools and software to diagnose and resolve mat defects, proactively identify potential issues, and implement preventative repairs. Proven ability to collaborate with design engineers to develop innovative mat designs for enhanced durability and performance. Demonstrated leadership qualities in training and supervising junior repairers, ensuring knowledge transfer and maintaining high-quality workmanship.

Education

Associate of Science in Composites Manufacturing

June 2015

Skills

- Resin Application

- Fiber Cutting

- Laminating Techniques

- Composite Repair Techniques

- Surface Preparation

- Gelcoat Application

Work Experience

Mat Repairer

- Established and maintained inventory of spare parts, ensuring timely repairs and minimizing production interruptions.

- Developed and implemented a comprehensive mat repair and maintenance program, reducing equipment downtime by 20%.

- Utilized software tools to track and document mat repairs, providing detailed reports for performance analysis.

- Trained and supervised junior mat repairers, ensuring knowledge transfer and maintaining highquality workmanship.

Mat Repairer

- Repaired and replaced damaged conveyor mats, ensuring optimal material flow and preventing production downtime.

- Utilized specialized tools and techniques to identify and diagnose mat defects, minimizing downtime and maintenance costs.

- Inspected and assessed mat integrity, proactively identifying potential issues and implementing preventative repairs.

- Collaborated with design engineers to develop and implement improved mat designs to enhance durability and performance.

Accomplishments

- Optimized the mat repair process, reducing downtime by 35% through innovative techniques and proactive maintenance.

- Established a comprehensive mat repair system, streamlining operations and enhancing efficiency by 20%.

- Developed a specialized repair technique for highimpact mats, extending their lifespan by 40% and reducing replacement costs.

- Led a project to implement a preventive mat maintenance program, reducing equipment breakdowns by 25%.

- Collaborated with engineers to design and implement an ergonomic mat repair workstation, improving safety and productivity.

Awards

- Recognized as a top performer in Mat Repair for outstanding contributions to the team.

- Received the Excellence in Mat Repair Award for consistently exceeding quality standards and customer expectations.

- Honored with the Safety Award for maintaining an exemplary safety record and promoting workplace safety awareness.

- Recognized by the industry association for outstanding achievements in Mat Repair and contribution to the field.

Certificates

- American Composites Manufacturers Association (ACMA)

- National Institute for Composite Technologies (NICOM)

- Composite Repair Certified (CRC)

- National Center for Composites Manufacturing (NCCM)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Mat Repairer

- Highlight your experience with different types of conveyor mats and repair techniques.

- Showcase your knowledge of composite materials and their properties.

- Emphasize your ability to work independently and as part of a team.

- Provide specific examples of how you have improved mat performance and reduced downtime.

Essential Experience Highlights for a Strong Mat Repairer Resume

- Repaired and replaced damaged conveyor mats, ensuring optimal material flow and preventing production downtime.

- Utilized specialized tools and techniques to identify and diagnose mat defects, minimizing downtime and maintenance costs.

- Inspected and assessed mat integrity, proactively identifying potential issues and implementing preventative repairs.

- Collaborated with design engineers to develop and implement improved mat designs to enhance durability and performance.

- Established and maintained inventory of spare parts, ensuring timely repairs and minimizing production interruptions.

Frequently Asked Questions (FAQ’s) For Mat Repairer

What are the key skills and qualifications required to be a successful Mat Repairer?

A successful Mat Repairer should possess a strong understanding of composite materials, repair techniques, and conveyor systems. They should be skilled in utilizing specialized tools and software to diagnose and resolve mat defects, and have a proactive approach to identifying potential issues and implementing preventative repairs. Additionally, they should be able to work independently and as part of a team, and have excellent communication and interpersonal skills.

What are the career prospects for Mat Repairers?

Mat Repairers are in high demand in industries that use conveyor systems, such as manufacturing, mining, and food processing. With experience and additional training, they can advance to roles such as Supervisor or Manager, or specialize in specific areas such as composite repair or conveyor maintenance.

What is the work environment like for Mat Repairers?

Mat Repairers typically work in industrial settings, such as factories or warehouses. They may work in confined spaces or at heights, and may be exposed to noise, dust, and chemicals. They should be physically fit and able to lift heavy objects.

What are the safety precautions that Mat Repairers should take?

Mat Repairers should always wear appropriate safety gear, such as gloves, safety glasses, and earplugs. They should be aware of the potential hazards of working with conveyor systems, such as moving parts, pinch points, and electrical hazards. They should also follow proper lockout/tagout procedures when working on or near conveyor systems.

What are the industry trends and advancements that are impacting Mat Repairers?

The use of composite materials in conveyor mats is increasing due to their durability and lightweight properties. Additionally, the use of automated repair techniques, such as robotic welding and laser cutting, is becoming more common. Mat Repairers should stay up-to-date on these trends and advancements to remain competitive in the field.