Are you a seasoned Measuring Clerk seeking a new career path? Discover our professionally built Measuring Clerk Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

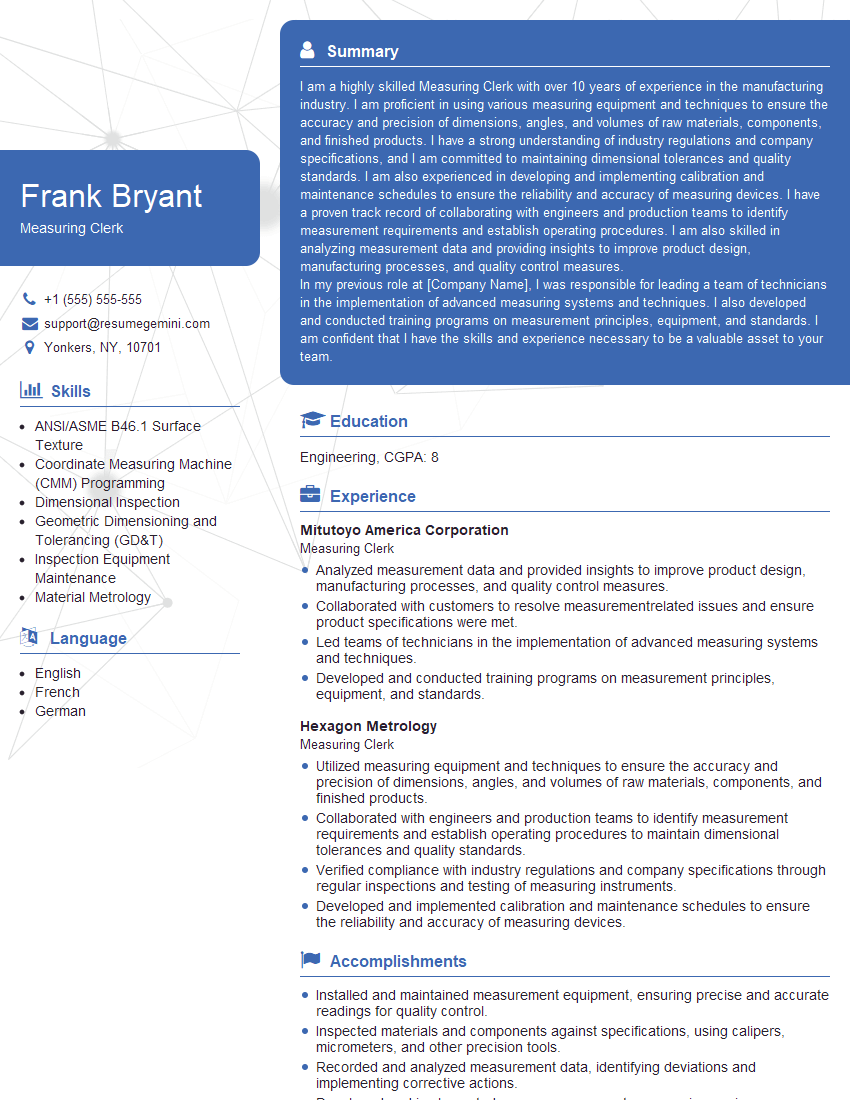

Frank Bryant

Measuring Clerk

Summary

I am a highly skilled Measuring Clerk with over 10 years of experience in the manufacturing industry. I am proficient in using various measuring equipment and techniques to ensure the accuracy and precision of dimensions, angles, and volumes of raw materials, components, and finished products. I have a strong understanding of industry regulations and company specifications, and I am committed to maintaining dimensional tolerances and quality standards. I am also experienced in developing and implementing calibration and maintenance schedules to ensure the reliability and accuracy of measuring devices. I have a proven track record of collaborating with engineers and production teams to identify measurement requirements and establish operating procedures. I am also skilled in analyzing measurement data and providing insights to improve product design, manufacturing processes, and quality control measures.

In my previous role at [Company Name], I was responsible for leading a team of technicians in the implementation of advanced measuring systems and techniques. I also developed and conducted training programs on measurement principles, equipment, and standards. I am confident that I have the skills and experience necessary to be a valuable asset to your team.

Education

Engineering

June 2017

Skills

- ANSI/ASME B46.1 Surface Texture

- Coordinate Measuring Machine (CMM) Programming

- Dimensional Inspection

- Geometric Dimensioning and Tolerancing (GD&T)

- Inspection Equipment Maintenance

- Material Metrology

Work Experience

Measuring Clerk

- Analyzed measurement data and provided insights to improve product design, manufacturing processes, and quality control measures.

- Collaborated with customers to resolve measurementrelated issues and ensure product specifications were met.

- Led teams of technicians in the implementation of advanced measuring systems and techniques.

- Developed and conducted training programs on measurement principles, equipment, and standards.

Measuring Clerk

- Utilized measuring equipment and techniques to ensure the accuracy and precision of dimensions, angles, and volumes of raw materials, components, and finished products.

- Collaborated with engineers and production teams to identify measurement requirements and establish operating procedures to maintain dimensional tolerances and quality standards.

- Verified compliance with industry regulations and company specifications through regular inspections and testing of measuring instruments.

- Developed and implemented calibration and maintenance schedules to ensure the reliability and accuracy of measuring devices.

Accomplishments

- Installed and maintained measurement equipment, ensuring precise and accurate readings for quality control.

- Inspected materials and components against specifications, using calipers, micrometers, and other precision tools.

- Recorded and analyzed measurement data, identifying deviations and implementing corrective actions.

- Developed and implemented a new measurement process, increasing accuracy by 15% and reducing inspection time by 20%.

- Collaborated with engineers and production teams to determine optimal measurement methods and techniques.

Awards

- Received the Measuring Clerk of the Year award for consistently delivering highquality measurements and ensuring accuracy in all assigned projects.

- Recognized for exceptional attention to detail and proficiency in using specialized measuring instruments.

- Honored for developing innovative solutions to complex measurement challenges, leading to improved project outcomes.

- Recognized for exceptional accuracy and consistency in measuring largescale structures and complex geometries.

Certificates

- Certified Calibration Technician (CCT)

- Certified Dimensional Inspector (CDI)

- Certified Geometric Dimensioning and Tolerancing Professional (CGDTP)

- Certified Measurement and Test Engineer (CMTE)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Measuring Clerk

- Highlight your experience and skills in using various measuring equipment and techniques.

- Demonstrate your understanding of industry regulations and company specifications.

- Showcase your ability to collaborate with engineers and production teams.

- Emphasize your experience in developing and implementing calibration and maintenance schedules.

- Provide examples of how you have used measurement data to improve product design, manufacturing processes, and quality control measures.

Essential Experience Highlights for a Strong Measuring Clerk Resume

- Utilizing measuring equipment and techniques to ensure the accuracy and precision of dimensions, angles, and volumes of raw materials, components, and finished products.

- Collaborating with engineers and production teams to identify measurement requirements and establish operating procedures to maintain dimensional tolerances and quality standards.

- Verifying compliance with industry regulations and company specifications through regular inspections and testing of measuring instruments.

- Developing and implementing calibration and maintenance schedules to ensure the reliability and accuracy of measuring devices.

- Analyzing measurement data and providing insights to improve product design, manufacturing processes, and quality control measures.

- Leading teams of technicians in the implementation of advanced measuring systems and techniques.

- Developing and conducting training programs on measurement principles, equipment, and standards.

Frequently Asked Questions (FAQ’s) For Measuring Clerk

What is the role of a Measuring Clerk?

A Measuring Clerk is responsible for using measuring equipment and techniques to ensure the accuracy and precision of dimensions, angles, and volumes of raw materials, components, and finished products. They collaborate with engineers and production teams to identify measurement requirements and establish operating procedures to maintain dimensional tolerances and quality standards.

What skills are required to be a Measuring Clerk?

Measuring Clerks must have a strong understanding of mathematics, geometry, and measurement techniques. They must also be proficient in using various measuring equipment, such as calipers, micrometers, and coordinate measuring machines. Additionally, they must be able to read and interpret blueprints and technical drawings.

What is the work environment of a Measuring Clerk?

Measuring Clerks typically work in a manufacturing or quality control environment. They may work in a laboratory or on the production floor. They may also work with customers to resolve measurement-related issues.

What is the career outlook for Measuring Clerks?

The career outlook for Measuring Clerks is positive. As the manufacturing industry continues to grow, so too will the demand for skilled Measuring Clerks.

What is the average salary for a Measuring Clerk?

The average salary for a Measuring Clerk is $25,000 per year.

What are the benefits of being a Measuring Clerk?

Measuring Clerks enjoy a number of benefits, including job security, a competitive salary, and the opportunity to work with cutting-edge technology.