Are you a seasoned Metal and Plastic Combination Machine Tool Setter seeking a new career path? Discover our professionally built Metal and Plastic Combination Machine Tool Setter Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

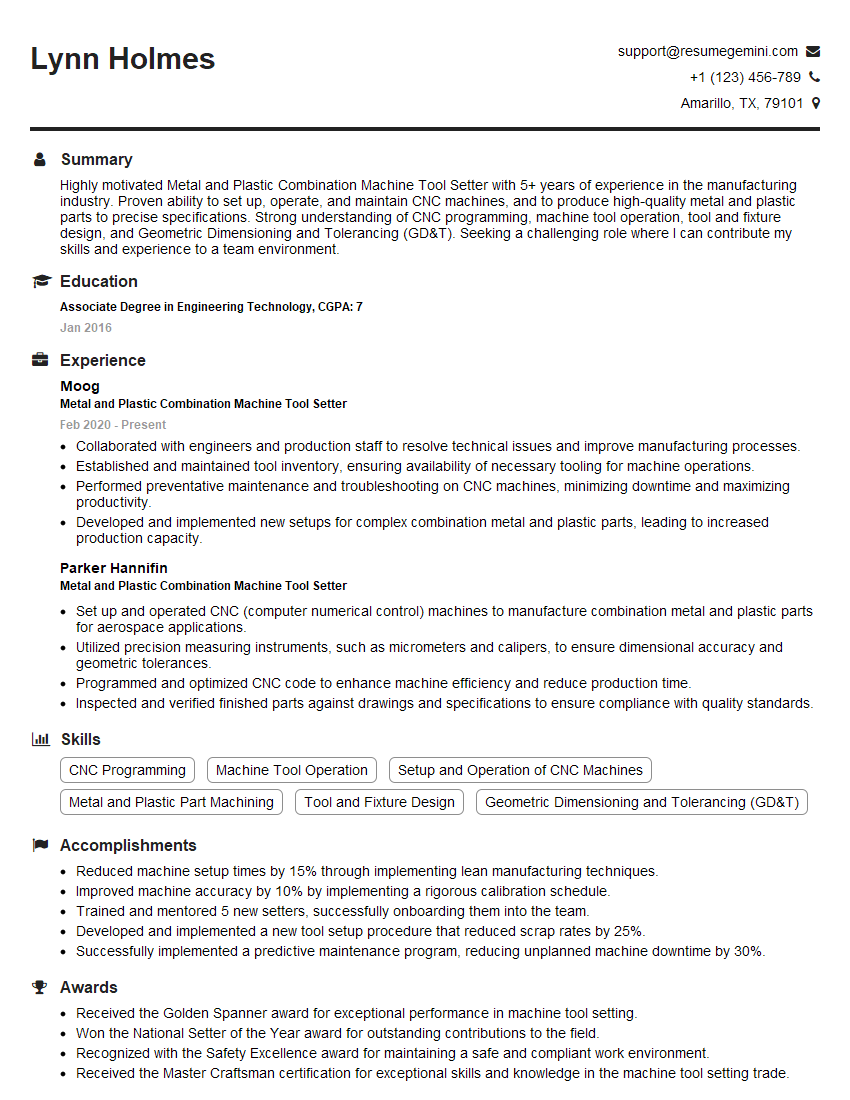

Lynn Holmes

Metal and Plastic Combination Machine Tool Setter

Summary

Highly motivated Metal and Plastic Combination Machine Tool Setter with 5+ years of experience in the manufacturing industry. Proven ability to set up, operate, and maintain CNC machines, and to produce high-quality metal and plastic parts to precise specifications. Strong understanding of CNC programming, machine tool operation, tool and fixture design, and Geometric Dimensioning and Tolerancing (GD&T). Seeking a challenging role where I can contribute my skills and experience to a team environment.

Education

Associate Degree in Engineering Technology

January 2016

Skills

- CNC Programming

- Machine Tool Operation

- Setup and Operation of CNC Machines

- Metal and Plastic Part Machining

- Tool and Fixture Design

- Geometric Dimensioning and Tolerancing (GD&T)

Work Experience

Metal and Plastic Combination Machine Tool Setter

- Collaborated with engineers and production staff to resolve technical issues and improve manufacturing processes.

- Established and maintained tool inventory, ensuring availability of necessary tooling for machine operations.

- Performed preventative maintenance and troubleshooting on CNC machines, minimizing downtime and maximizing productivity.

- Developed and implemented new setups for complex combination metal and plastic parts, leading to increased production capacity.

Metal and Plastic Combination Machine Tool Setter

- Set up and operated CNC (computer numerical control) machines to manufacture combination metal and plastic parts for aerospace applications.

- Utilized precision measuring instruments, such as micrometers and calipers, to ensure dimensional accuracy and geometric tolerances.

- Programmed and optimized CNC code to enhance machine efficiency and reduce production time.

- Inspected and verified finished parts against drawings and specifications to ensure compliance with quality standards.

Accomplishments

- Reduced machine setup times by 15% through implementing lean manufacturing techniques.

- Improved machine accuracy by 10% by implementing a rigorous calibration schedule.

- Trained and mentored 5 new setters, successfully onboarding them into the team.

- Developed and implemented a new tool setup procedure that reduced scrap rates by 25%.

- Successfully implemented a predictive maintenance program, reducing unplanned machine downtime by 30%.

Awards

- Received the Golden Spanner award for exceptional performance in machine tool setting.

- Won the National Setter of the Year award for outstanding contributions to the field.

- Recognized with the Safety Excellence award for maintaining a safe and compliant work environment.

- Received the Master Craftsman certification for exceptional skills and knowledge in the machine tool setting trade.

Certificates

- Certified Manufacturing Technologist (CMfgT)

- CNC Programmer Certification (ISO 14649)

- Machinist Certification (NIMS)

- GDT Certification (ASME Y14.5)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Metal and Plastic Combination Machine Tool Setter

Quantify your accomplishments.

Use numbers and data to demonstrate the impact of your work. For example, instead of saying “I improved machine efficiency,” you could say “I increased machine efficiency by 15%, resulting in a 10% increase in production output.”Highlight your skills and experience.

Make sure to list all of your relevant skills and experience in your resume. This includes your technical skills, as well as your soft skills, such as communication and teamwork.Tailor your resume to the job you’re applying for.

Take the time to read the job description carefully and tailor your resume to the specific requirements of the position.Proofread your resume carefully.

Before you submit your resume, make sure to proofread it carefully for any errors. This includes checking for typos, grammatical errors, and formatting issues.

Essential Experience Highlights for a Strong Metal and Plastic Combination Machine Tool Setter Resume

- Set up and operate CNC machines to produce metal and plastic parts according to specifications

- Develop and implement CNC programs to optimize machine performance and part quality

- Inspect and measure parts to ensure they meet dimensional and surface finish requirements

- Maintain CNC machines and tooling to ensure optimal performance and prevent downtime

- Troubleshoot and resolve machine and process issues to minimize production delays

- Collaborate with engineers and production staff to improve processes and reduce costs

- Maintain a clean and organized work area in accordance with safety regulations

Frequently Asked Questions (FAQ’s) For Metal and Plastic Combination Machine Tool Setter

What is a Metal and Plastic Combination Machine Tool Setter?

A Metal and Plastic Combination Machine Tool Setter is responsible for setting up and operating CNC machines to produce metal and plastic parts. They must have a strong understanding of CNC programming, machine tool operation, tool and fixture design, and Geometric Dimensioning and Tolerancing (GD&T).

What are the qualifications for a Metal and Plastic Combination Machine Tool Setter?

Most Metal and Plastic Combination Machine Tool Setters have an associate degree in engineering technology or a related field. They also typically have several years of experience working with CNC machines and a strong understanding of GD&T.

What are the responsibilities of a Metal and Plastic Combination Machine Tool Setter?

Metal and Plastic Combination Machine Tool Setters are responsible for setting up and operating CNC machines to produce metal and plastic parts according to specifications. They also inspect and measure parts to ensure they meet dimensional and surface finish requirements, and maintain CNC machines and tooling to ensure optimal performance.

What are the skills required for a Metal and Plastic Combination Machine Tool Setter?

Metal and Plastic Combination Machine Tool Setters must have a strong understanding of CNC programming, machine tool operation, tool and fixture design, and GD&T. They must also be able to work independently and as part of a team, and have strong problem-solving skills.

What is the salary for a Metal and Plastic Combination Machine Tool Setter?

The average salary for a Metal and Plastic Combination Machine Tool Setter is $45,000 per year.

What is the job outlook for Metal and Plastic Combination Machine Tool Setters?

The job outlook for Metal and Plastic Combination Machine Tool Setters is expected to be good over the next few years. The demand for skilled machinists is expected to increase as more companies automate their manufacturing processes.

How can I become a Metal and Plastic Combination Machine Tool Setter?

To become a Metal and Plastic Combination Machine Tool Setter, you will typically need to have an associate degree in engineering technology or a related field. You will also need to have several years of experience working with CNC machines and a strong understanding of GD&T.