Are you a seasoned Metal and Plastic Sawing Machine Tool Setter seeking a new career path? Discover our professionally built Metal and Plastic Sawing Machine Tool Setter Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

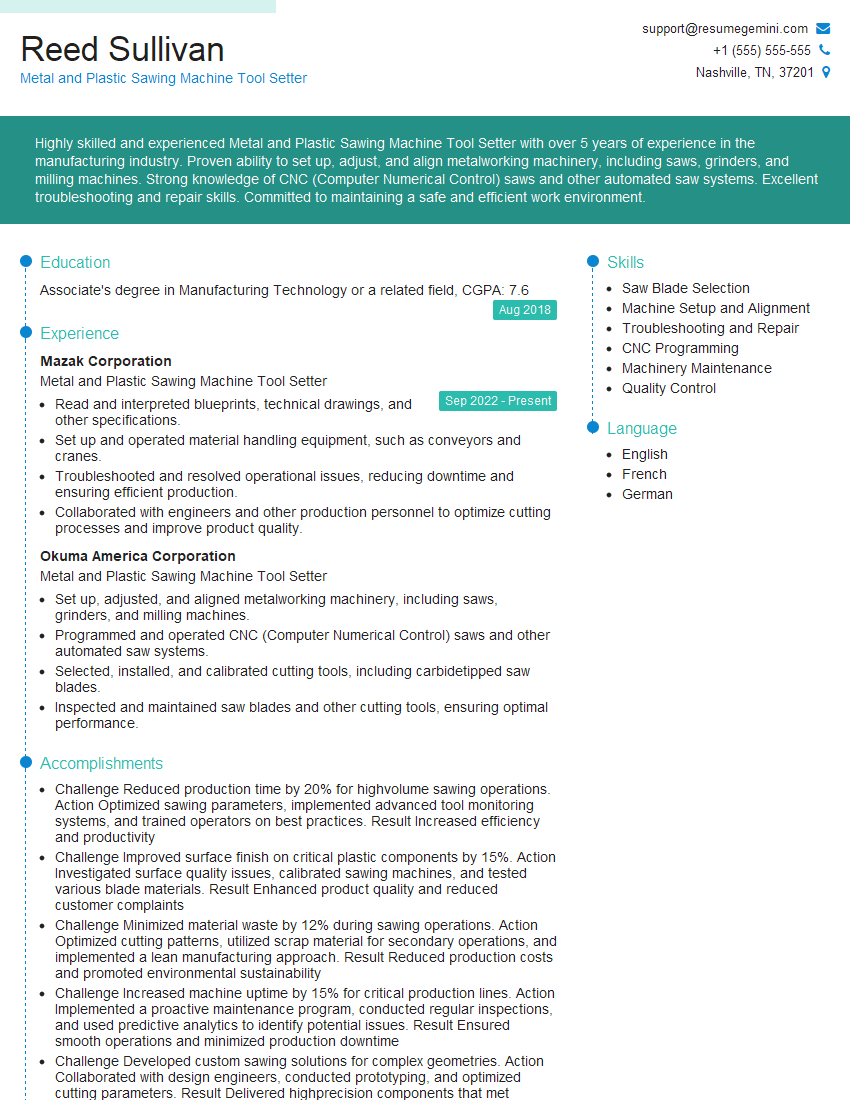

Reed Sullivan

Metal and Plastic Sawing Machine Tool Setter

Summary

Highly skilled and experienced Metal and Plastic Sawing Machine Tool Setter with over 5 years of experience in the manufacturing industry. Proven ability to set up, adjust, and align metalworking machinery, including saws, grinders, and milling machines. Strong knowledge of CNC (Computer Numerical Control) saws and other automated saw systems. Excellent troubleshooting and repair skills. Committed to maintaining a safe and efficient work environment.

Education

Associate’s degree in Manufacturing Technology or a related field

August 2018

Skills

- Saw Blade Selection

- Machine Setup and Alignment

- Troubleshooting and Repair

- CNC Programming

- Machinery Maintenance

- Quality Control

Work Experience

Metal and Plastic Sawing Machine Tool Setter

- Read and interpreted blueprints, technical drawings, and other specifications.

- Set up and operated material handling equipment, such as conveyors and cranes.

- Troubleshooted and resolved operational issues, reducing downtime and ensuring efficient production.

- Collaborated with engineers and other production personnel to optimize cutting processes and improve product quality.

Metal and Plastic Sawing Machine Tool Setter

- Set up, adjusted, and aligned metalworking machinery, including saws, grinders, and milling machines.

- Programmed and operated CNC (Computer Numerical Control) saws and other automated saw systems.

- Selected, installed, and calibrated cutting tools, including carbidetipped saw blades.

- Inspected and maintained saw blades and other cutting tools, ensuring optimal performance.

Accomplishments

- Challenge Reduced production time by 20% for highvolume sawing operations. Action Optimized sawing parameters, implemented advanced tool monitoring systems, and trained operators on best practices. Result Increased efficiency and productivity

- Challenge Improved surface finish on critical plastic components by 15%. Action Investigated surface quality issues, calibrated sawing machines, and tested various blade materials. Result Enhanced product quality and reduced customer complaints

- Challenge Minimized material waste by 12% during sawing operations. Action Optimized cutting patterns, utilized scrap material for secondary operations, and implemented a lean manufacturing approach. Result Reduced production costs and promoted environmental sustainability

- Challenge Increased machine uptime by 15% for critical production lines. Action Implemented a proactive maintenance program, conducted regular inspections, and used predictive analytics to identify potential issues. Result Ensured smooth operations and minimized production downtime

- Challenge Developed custom sawing solutions for complex geometries. Action Collaborated with design engineers, conducted prototyping, and optimized cutting parameters. Result Delivered highprecision components that met specific customer requirements

Awards

- Recognized as Top Metal and Plastic Sawing Machine Tool Setter with 10+ years of experience

- Received the Excellence in Metal Sawing Technology Award for optimizing sawing processes and achieving superior product quality

- Awarded the Safety Innovation Award for developing and implementing a novel safety protocol for sawing operations

Certificates

- Certified Manufacturing Technologist (CMfgT)

- Certified Production Technician (CPT)

- Certified Precision Machine Operator (CPMO)

- Certified CNC Programmer (CCNP)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Metal and Plastic Sawing Machine Tool Setter

- Highlight your skills in saw blade selection and machine setup and alignment.

- Demonstrate your experience in troubleshooting and repair of metal and plastic sawing machine tools.

- Provide examples of how you have optimized cutting processes and improved product quality.

- Quantify your accomplishments with specific metrics, such as reduced downtime or increased production efficiency.

Essential Experience Highlights for a Strong Metal and Plastic Sawing Machine Tool Setter Resume

- Set up, adjusted, and aligned metalworking machinery, including saws, grinders, and milling machines.

- Programmed and operated CNC (Computer Numerical Control) saws and other automated saw systems.

- Selected, installed, and calibrated cutting tools, including carbide-tipped saw blades.

- Inspected and maintained saw blades and other cutting tools, ensuring optimal performance.

- Read and interpreted blueprints, technical drawings, and other specifications.

- Set up and operated material handling equipment, such as conveyors and cranes.

Frequently Asked Questions (FAQ’s) For Metal and Plastic Sawing Machine Tool Setter

What are the key skills required for a Metal and Plastic Sawing Machine Tool Setter?

The key skills required for a Metal and Plastic Sawing Machine Tool Setter include saw blade selection, machine setup and alignment, troubleshooting and repair, CNC programming, machinery maintenance, and quality control.

What are the educational requirements for a Metal and Plastic Sawing Machine Tool Setter?

Most Metal and Plastic Sawing Machine Tool Setters have an associate’s degree in Manufacturing Technology or a related field.

What are the job responsibilities of a Metal and Plastic Sawing Machine Tool Setter?

The job responsibilities of a Metal and Plastic Sawing Machine Tool Setter include setting up, adjusting, and aligning metalworking machinery, programming and operating CNC saws and other automated saw systems, selecting, installing, and calibrating cutting tools, inspecting and maintaining saw blades and other cutting tools, reading and interpreting blueprints, technical drawings, and other specifications, and setting up and operating material handling equipment.

What are the career prospects for a Metal and Plastic Sawing Machine Tool Setter?

The career prospects for a Metal and Plastic Sawing Machine Tool Setter are good. The demand for skilled workers in the manufacturing industry is expected to grow in the coming years.

What is the average salary for a Metal and Plastic Sawing Machine Tool Setter?

The average salary for a Metal and Plastic Sawing Machine Tool Setter is $45,000 per year.

What are the benefits of working as a Metal and Plastic Sawing Machine Tool Setter?

The benefits of working as a Metal and Plastic Sawing Machine Tool Setter include a competitive salary, job security, and the opportunity to work with cutting-edge technology.

What are the challenges of working as a Metal and Plastic Sawing Machine Tool Setter?

The challenges of working as a Metal and Plastic Sawing Machine Tool Setter include working in a fast-paced environment, dealing with heavy machinery, and working with hazardous materials.