Are you a seasoned Metal and Plastic Shear and Slitter Machine Setter seeking a new career path? Discover our professionally built Metal and Plastic Shear and Slitter Machine Setter Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

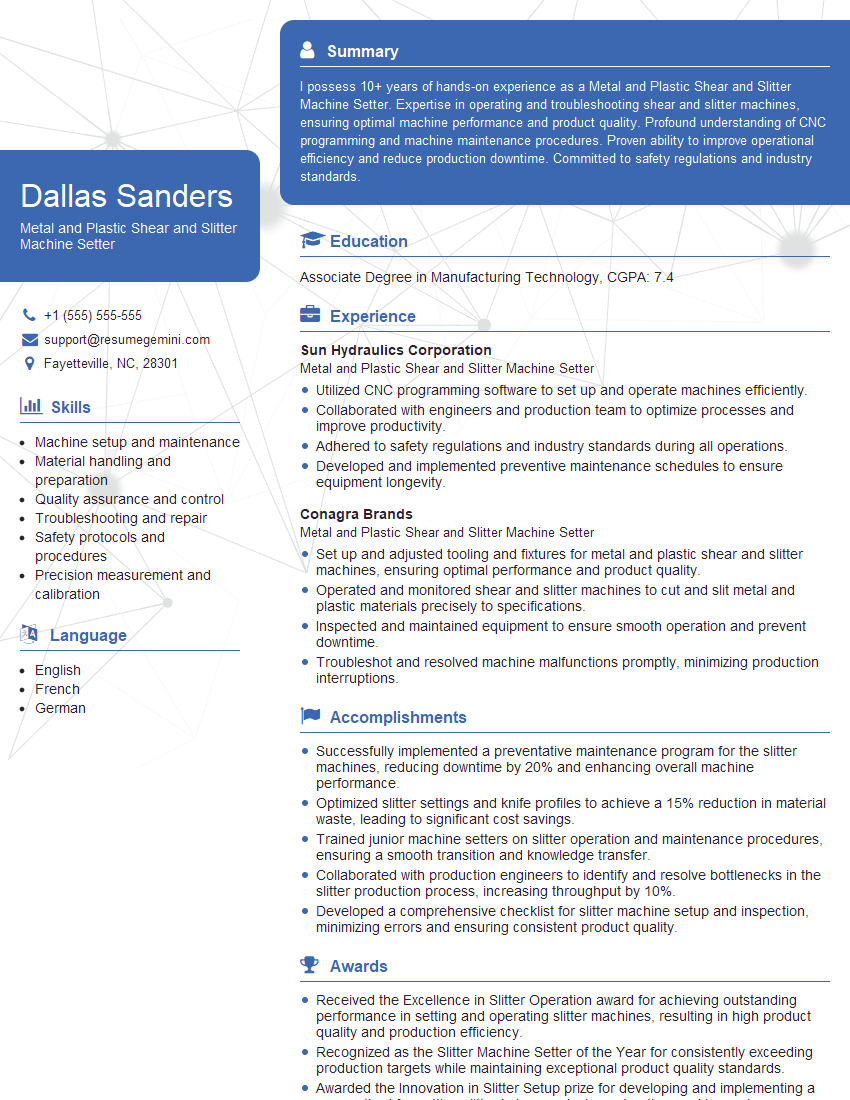

Dallas Sanders

Metal and Plastic Shear and Slitter Machine Setter

Summary

I possess 10+ years of hands-on experience as a Metal and Plastic Shear and Slitter Machine Setter. Expertise in operating and troubleshooting shear and slitter machines, ensuring optimal machine performance and product quality. Profound understanding of CNC programming and machine maintenance procedures. Proven ability to improve operational efficiency and reduce production downtime. Committed to safety regulations and industry standards.

Education

Associate Degree in Manufacturing Technology

March 2016

Skills

- Machine setup and maintenance

- Material handling and preparation

- Quality assurance and control

- Troubleshooting and repair

- Safety protocols and procedures

- Precision measurement and calibration

Work Experience

Metal and Plastic Shear and Slitter Machine Setter

- Utilized CNC programming software to set up and operate machines efficiently.

- Collaborated with engineers and production team to optimize processes and improve productivity.

- Adhered to safety regulations and industry standards during all operations.

- Developed and implemented preventive maintenance schedules to ensure equipment longevity.

Metal and Plastic Shear and Slitter Machine Setter

- Set up and adjusted tooling and fixtures for metal and plastic shear and slitter machines, ensuring optimal performance and product quality.

- Operated and monitored shear and slitter machines to cut and slit metal and plastic materials precisely to specifications.

- Inspected and maintained equipment to ensure smooth operation and prevent downtime.

- Troubleshot and resolved machine malfunctions promptly, minimizing production interruptions.

Accomplishments

- Successfully implemented a preventative maintenance program for the slitter machines, reducing downtime by 20% and enhancing overall machine performance.

- Optimized slitter settings and knife profiles to achieve a 15% reduction in material waste, leading to significant cost savings.

- Trained junior machine setters on slitter operation and maintenance procedures, ensuring a smooth transition and knowledge transfer.

- Collaborated with production engineers to identify and resolve bottlenecks in the slitter production process, increasing throughput by 10%.

- Developed a comprehensive checklist for slitter machine setup and inspection, minimizing errors and ensuring consistent product quality.

Awards

- Received the Excellence in Slitter Operation award for achieving outstanding performance in setting and operating slitter machines, resulting in high product quality and production efficiency.

- Recognized as the Slitter Machine Setter of the Year for consistently exceeding production targets while maintaining exceptional product quality standards.

- Awarded the Innovation in Slitter Setup prize for developing and implementing a new method for setting slitter knives, reducing setup time and improving precision.

Certificates

- Certified Machine Setter Operator (CMSO)

- Certified OSHA Safety Trainer (COST)

- Certified Lean Manufacturing Professional (CLMP)

- Certified Six Sigma Green Belt (CSSGB)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Metal and Plastic Shear and Slitter Machine Setter

- Highlight your technical expertise in machine setup, operation, and maintenance.

- Quantify your accomplishments, such as reducing downtime or improving production efficiency.

- Demonstrate your ability to work independently and as part of a team.

- Showcase your problem-solving skills and ability to troubleshoot complex issues.

- Emphasize your commitment to safety and industry standards.

Essential Experience Highlights for a Strong Metal and Plastic Shear and Slitter Machine Setter Resume

- Set up and adjusted tooling and fixtures to optimize machine performance and product quality

- Operated and monitored shear and slitter machines to precisely cut and slit metal and plastic materials

- Performed regular equipment inspections and maintenance to prevent downtime and ensure smooth operation

- Troubleshooted and resolved machine malfunctions promptly, minimizing production interruptions

- Utilized CNC programming software to set up and operate machines efficiently

- Collaborated with engineers and production team to optimize processes and improve productivity

- Adhered to safety regulations and industry standards during all operations

Frequently Asked Questions (FAQ’s) For Metal and Plastic Shear and Slitter Machine Setter

What are the key skills required for a Metal and Plastic Shear and Slitter Machine Setter?

The key skills include machine setup and maintenance, material handling and preparation, quality assurance and control, troubleshooting and repair, safety protocols and procedures, precision measurement and calibration.

What are the typical responsibilities of a Metal and Plastic Shear and Slitter Machine Setter?

Common responsibilities involve setting up and adjusting tooling and fixtures, operating and monitoring shear and slitter machines, inspecting and maintaining equipment, troubleshooting and resolving machine malfunctions, and adhering to safety regulations.

What are the top companies that hire Metal and Plastic Shear and Slitter Machine Setters?

Top companies include Sun Hydraulics Corporation and Conagra Brands.

What qualifications are needed to become a Metal and Plastic Shear and Slitter Machine Setter?

An Associate Degree in Manufacturing Technology or a related field is generally required.

What are the career prospects for a Metal and Plastic Shear and Slitter Machine Setter?

With experience, you can advance to roles such as Production Supervisor, Manufacturing Engineer, or Quality Control Manager.

What is the average salary for a Metal and Plastic Shear and Slitter Machine Setter?

The average salary in the United States is approximately $45,000 to $65,000 per year.

What are the job outlook and growth prospects for a Metal and Plastic Shear and Slitter Machine Setter?

The job outlook is expected to grow faster than average in the coming years due to increasing demand for skilled manufacturing professionals.