Are you a seasoned Metal Bench Patternmaker seeking a new career path? Discover our professionally built Metal Bench Patternmaker Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

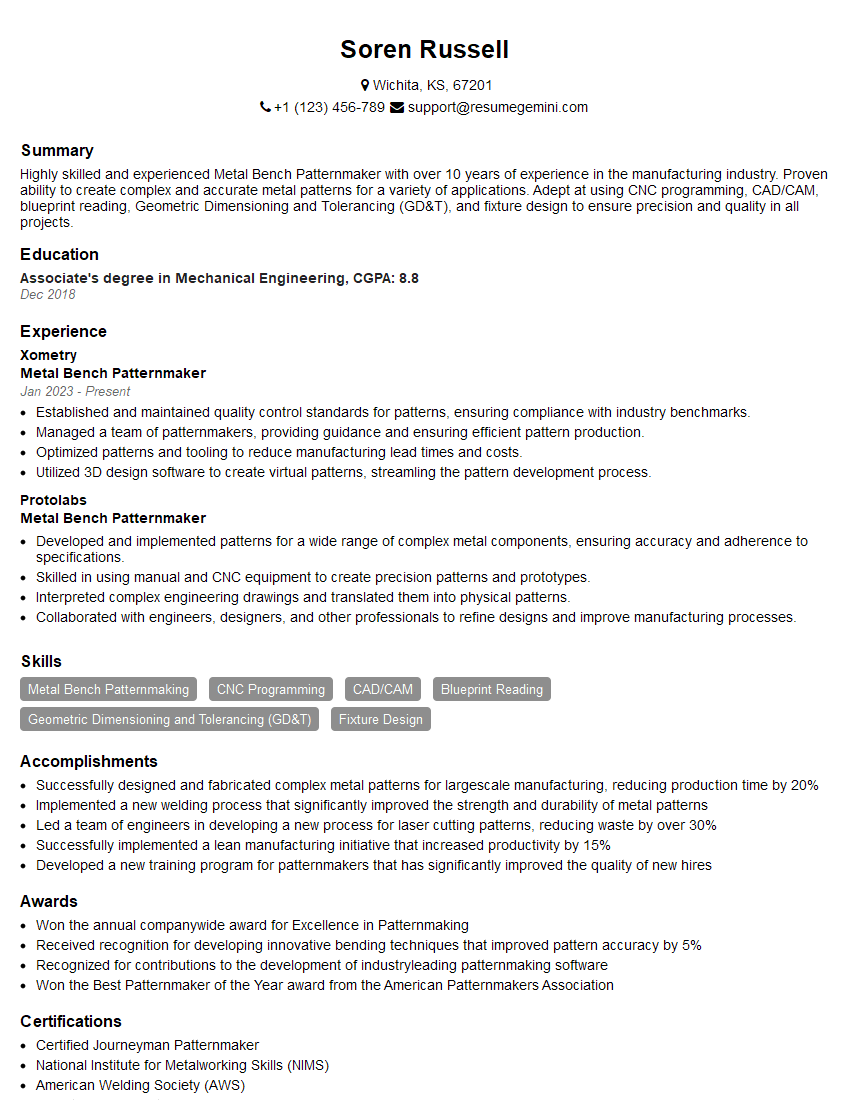

Soren Russell

Metal Bench Patternmaker

Summary

Highly skilled and experienced Metal Bench Patternmaker with over 10 years of experience in the manufacturing industry. Proven ability to create complex and accurate metal patterns for a variety of applications. Adept at using CNC programming, CAD/CAM, blueprint reading, Geometric Dimensioning and Tolerancing (GD&T), and fixture design to ensure precision and quality in all projects.

Education

Associate’s degree in Mechanical Engineering

December 2018

Skills

- Metal Bench Patternmaking

- CNC Programming

- CAD/CAM

- Blueprint Reading

- Geometric Dimensioning and Tolerancing (GD&T)

- Fixture Design

Work Experience

Metal Bench Patternmaker

- Established and maintained quality control standards for patterns, ensuring compliance with industry benchmarks.

- Managed a team of patternmakers, providing guidance and ensuring efficient pattern production.

- Optimized patterns and tooling to reduce manufacturing lead times and costs.

- Utilized 3D design software to create virtual patterns, streamling the pattern development process.

Metal Bench Patternmaker

- Developed and implemented patterns for a wide range of complex metal components, ensuring accuracy and adherence to specifications.

- Skilled in using manual and CNC equipment to create precision patterns and prototypes.

- Interpreted complex engineering drawings and translated them into physical patterns.

- Collaborated with engineers, designers, and other professionals to refine designs and improve manufacturing processes.

Accomplishments

- Successfully designed and fabricated complex metal patterns for largescale manufacturing, reducing production time by 20%

- Implemented a new welding process that significantly improved the strength and durability of metal patterns

- Led a team of engineers in developing a new process for laser cutting patterns, reducing waste by over 30%

- Successfully implemented a lean manufacturing initiative that increased productivity by 15%

- Developed a new training program for patternmakers that has significantly improved the quality of new hires

Awards

- Won the annual companywide award for Excellence in Patternmaking

- Received recognition for developing innovative bending techniques that improved pattern accuracy by 5%

- Recognized for contributions to the development of industryleading patternmaking software

- Won the Best Patternmaker of the Year award from the American Patternmakers Association

Certificates

- Certified Journeyman Patternmaker

- National Institute for Metalworking Skills (NIMS)

- American Welding Society (AWS)

- Society of Manufacturing Engineers (SME)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Metal Bench Patternmaker

- Highlight your technical skills and experience in Metal Bench Patternmaking in your resume.

- Quantify your accomplishments and provide specific examples of your contributions to past projects.

- Showcase your proficiency in using industry-standard software and equipment, such as CNC machines, CAD/CAM systems, and GD&T.

- Emphasize your attention to detail, accuracy, and commitment to quality in your work.

- Demonstrate your ability to work independently and as part of a team in a manufacturing environment.

Essential Experience Highlights for a Strong Metal Bench Patternmaker Resume

- Develop and create metal patterns for various manufacturing processes, including casting, forging, and stamping.

- Utilize CNC programming, CAD/CAM, and GD&T to ensure accuracy and precision in pattern creation.

- Interpret and analyze blueprints, technical drawings, and specifications to determine pattern requirements.

- Design and build fixtures to hold patterns and castings securely during manufacturing processes.

- Collaborate with engineers, designers, and other members of the manufacturing team to ensure project success.

- Stay abreast of industry trends and advancements in patternmaking technologies and techniques.

- Maintain a clean and organized work area, adhering to safety protocols and regulations.

Frequently Asked Questions (FAQ’s) For Metal Bench Patternmaker

What is the primary role of a Metal Bench Patternmaker?

The primary role of a Metal Bench Patternmaker is to create physical patterns or models used to shape metal castings, forgings, or other metal parts during manufacturing processes.

What skills are required to be a successful Metal Bench Patternmaker?

Successful Metal Bench Patternmakers typically possess strong technical skills in metalworking, blueprint reading, CNC programming, CAD/CAM, and Geometric Dimensioning and Tolerancing (GD&T).

What industries employ Metal Bench Patternmakers?

Metal Bench Patternmakers are employed in various industries, including automotive, aerospace, construction, and consumer goods manufacturing.

What is the job outlook for Metal Bench Patternmakers?

The job outlook for Metal Bench Patternmakers is expected to be stable in the coming years due to the continuous demand for skilled professionals in the manufacturing sector.

What are some tips for writing a standout resume for a Metal Bench Patternmaker position?

To write a standout resume, highlight your technical skills, experience, and quantifiable accomplishments. Showcase your proficiency in industry-standard software and equipment and emphasize your attention to detail and commitment to quality.

What are the growth opportunities for Metal Bench Patternmakers?

Metal Bench Patternmakers with experience and expertise can advance to supervisory roles or specialize in specific areas of patternmaking, such as rapid prototyping or 3D printing.