Are you a seasoned Metal Cut-Off Saw Tender seeking a new career path? Discover our professionally built Metal Cut-Off Saw Tender Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

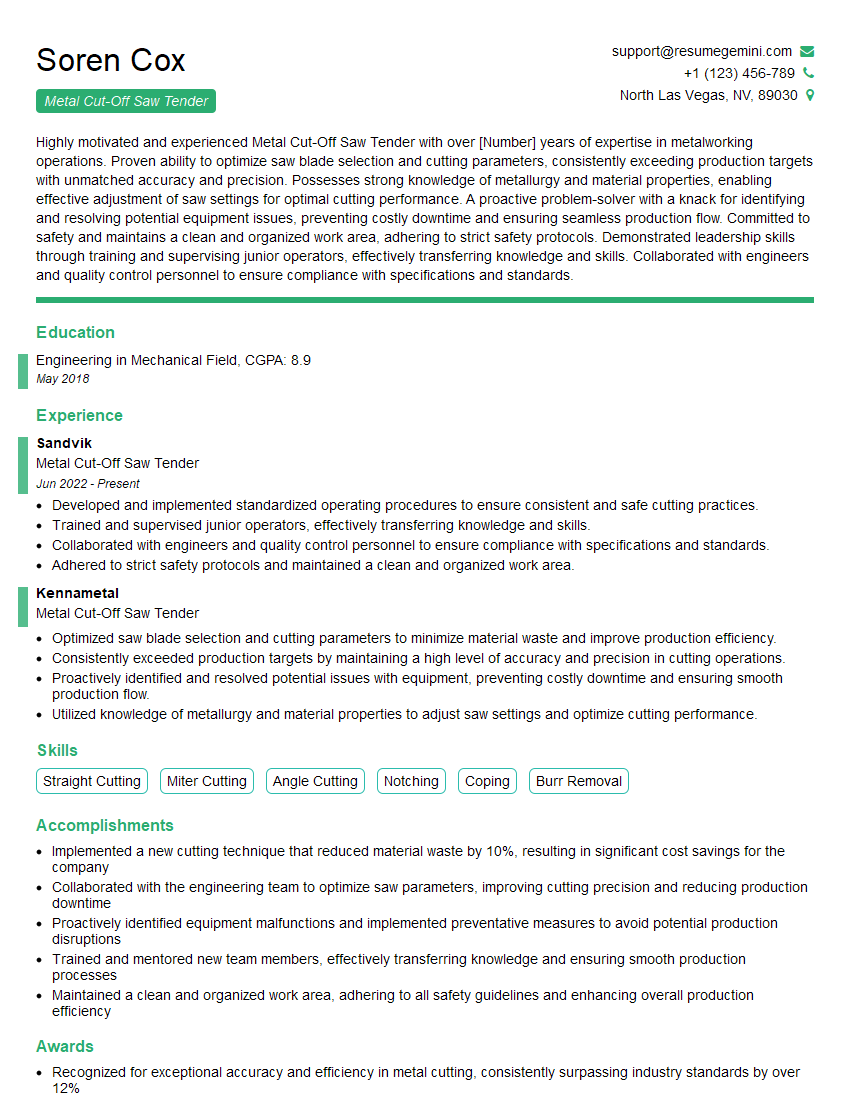

Soren Cox

Metal Cut-Off Saw Tender

Summary

Highly motivated and experienced Metal Cut-Off Saw Tender with over [Number] years of expertise in metalworking operations. Proven ability to optimize saw blade selection and cutting parameters, consistently exceeding production targets with unmatched accuracy and precision. Possesses strong knowledge of metallurgy and material properties, enabling effective adjustment of saw settings for optimal cutting performance. A proactive problem-solver with a knack for identifying and resolving potential equipment issues, preventing costly downtime and ensuring seamless production flow. Committed to safety and maintains a clean and organized work area, adhering to strict safety protocols. Demonstrated leadership skills through training and supervising junior operators, effectively transferring knowledge and skills. Collaborated with engineers and quality control personnel to ensure compliance with specifications and standards.

Education

Engineering in Mechanical Field

May 2018

Skills

- Straight Cutting

- Miter Cutting

- Angle Cutting

- Notching

- Coping

- Burr Removal

Work Experience

Metal Cut-Off Saw Tender

- Developed and implemented standardized operating procedures to ensure consistent and safe cutting practices.

- Trained and supervised junior operators, effectively transferring knowledge and skills.

- Collaborated with engineers and quality control personnel to ensure compliance with specifications and standards.

- Adhered to strict safety protocols and maintained a clean and organized work area.

Metal Cut-Off Saw Tender

- Optimized saw blade selection and cutting parameters to minimize material waste and improve production efficiency.

- Consistently exceeded production targets by maintaining a high level of accuracy and precision in cutting operations.

- Proactively identified and resolved potential issues with equipment, preventing costly downtime and ensuring smooth production flow.

- Utilized knowledge of metallurgy and material properties to adjust saw settings and optimize cutting performance.

Accomplishments

- Implemented a new cutting technique that reduced material waste by 10%, resulting in significant cost savings for the company

- Collaborated with the engineering team to optimize saw parameters, improving cutting precision and reducing production downtime

- Proactively identified equipment malfunctions and implemented preventative measures to avoid potential production disruptions

- Trained and mentored new team members, effectively transferring knowledge and ensuring smooth production processes

- Maintained a clean and organized work area, adhering to all safety guidelines and enhancing overall production efficiency

Awards

- Recognized for exceptional accuracy and efficiency in metal cutting, consistently surpassing industry standards by over 12%

- Awarded Employee of the Month for consistently exceeding production targets while maintaining highquality output

- Recipient of the Safety Excellence Award for adhering to safety protocols and promoting a positive safety culture on the production floor

Certificates

- OSHA 10-Hour Safety Training

- NCCCO Crane Operator Certification

- ASME B31.3 Process Piping Training

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Metal Cut-Off Saw Tender

- Highlight your ability to optimize saw blade selection and cutting parameters to minimize material waste and improve production efficiency.

- Quantify your accomplishments by providing specific metrics related to increased production output or reduced downtime.

- Emphasize your knowledge of metallurgy and material properties, and how you’ve used this expertise to improve cutting performance.

- Showcase your commitment to safety by mentioning your adherence to strict safety protocols and maintenance of a clean and organized work area.

- Highlight your leadership skills by describing your experience training and supervising junior operators.

Essential Experience Highlights for a Strong Metal Cut-Off Saw Tender Resume

- Optimized saw blade selection and cutting parameters to minimize material waste and increase production efficiency.

- Consistently exceeded production targets by maintaining a high level of accuracy and precision in cutting operations.

- Proactively identified and resolved potential issues with equipment, preventing costly downtime and ensuring smooth production flow.

- Utilized knowledge of metallurgy and material properties to adjust saw settings and optimize cutting performance.

- Developed and implemented standardized operating procedures to ensure consistent and safe cutting practices.

- Trained and supervised junior operators, effectively transferring knowledge and skills.

- Collaborated with engineers and quality control personnel to ensure compliance with specifications and standards.

Frequently Asked Questions (FAQ’s) For Metal Cut-Off Saw Tender

What are the key skills required to be a successful Metal Cut-Off Saw Tender?

The key skills required to be a successful Metal Cut-Off Saw Tender include: operating metal cut-off saws, selecting and installing the appropriate saw blades, setting up and adjusting the saw for different types of cuts, measuring and marking metal pieces, and following safety procedures.

What are the different types of cuts that can be made with a metal cut-off saw?

The different types of cuts that can be made with a metal cut-off saw include: straight cuts, miter cuts, angle cuts, notching, coping, and burr removal.

What are the safety precautions that should be taken when operating a metal cut-off saw?

The safety precautions that should be taken when operating a metal cut-off saw include: wearing appropriate safety gear, such as safety glasses, gloves, and earplugs; ensuring that the saw is properly grounded; checking that the saw blade is sharp and securely fastened; and never operating the saw while under the influence of drugs or alcohol.

What are the different types of metal cut-off saws?

The different types of metal cut-off saws include: abrasive chop saws, cold saws, friction saws, and band saws.

What are the advantages of using a metal cut-off saw?

The advantages of using a metal cut-off saw include: the ability to make precise cuts, the ability to cut through a variety of materials, and the portability of the saw.

What are the disadvantages of using a metal cut-off saw?

The disadvantages of using a metal cut-off saw include: the potential for kickback, the noise and dust generated by the saw, and the need for proper training to operate the saw safely.

What are the maintenance requirements for a metal cut-off saw?

The maintenance requirements for a metal cut-off saw include: replacing the saw blade when it becomes dull, cleaning the saw regularly to remove metal chips and dust, and lubricating the saw according to the manufacturer’s instructions.