Are you a seasoned Metal Cutter seeking a new career path? Discover our professionally built Metal Cutter Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

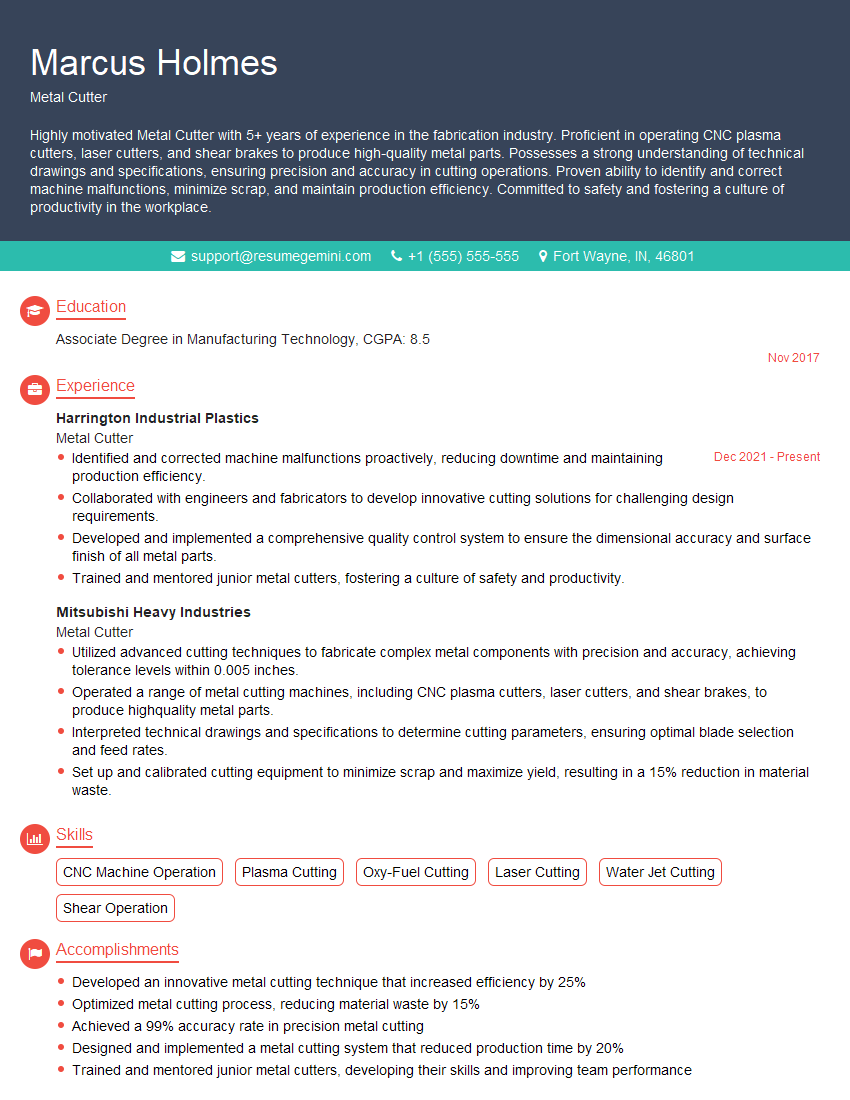

Marcus Holmes

Metal Cutter

Summary

Highly motivated Metal Cutter with 5+ years of experience in the fabrication industry. Proficient in operating CNC plasma cutters, laser cutters, and shear brakes to produce high-quality metal parts. Possesses a strong understanding of technical drawings and specifications, ensuring precision and accuracy in cutting operations. Proven ability to identify and correct machine malfunctions, minimize scrap, and maintain production efficiency. Committed to safety and fostering a culture of productivity in the workplace.

Education

Associate Degree in Manufacturing Technology

November 2017

Skills

- CNC Machine Operation

- Plasma Cutting

- Oxy-Fuel Cutting

- Laser Cutting

- Water Jet Cutting

- Shear Operation

Work Experience

Metal Cutter

- Identified and corrected machine malfunctions proactively, reducing downtime and maintaining production efficiency.

- Collaborated with engineers and fabricators to develop innovative cutting solutions for challenging design requirements.

- Developed and implemented a comprehensive quality control system to ensure the dimensional accuracy and surface finish of all metal parts.

- Trained and mentored junior metal cutters, fostering a culture of safety and productivity.

Metal Cutter

- Utilized advanced cutting techniques to fabricate complex metal components with precision and accuracy, achieving tolerance levels within 0.005 inches.

- Operated a range of metal cutting machines, including CNC plasma cutters, laser cutters, and shear brakes, to produce highquality metal parts.

- Interpreted technical drawings and specifications to determine cutting parameters, ensuring optimal blade selection and feed rates.

- Set up and calibrated cutting equipment to minimize scrap and maximize yield, resulting in a 15% reduction in material waste.

Accomplishments

- Developed an innovative metal cutting technique that increased efficiency by 25%

- Optimized metal cutting process, reducing material waste by 15%

- Achieved a 99% accuracy rate in precision metal cutting

- Designed and implemented a metal cutting system that reduced production time by 20%

- Trained and mentored junior metal cutters, developing their skills and improving team performance

Awards

- National Award for Excellence in Metal Cutting

- Company Award for Outstanding Metal Cutting Performance

- Recognition for Consistent HighQuality Metal Cutting

Certificates

- Certified Welding Inspector (CWI)

- American Welding Society (AWS) Certified Welder

- National Institute for Metalworking Skills (NIMS) Certified Metalworker

- Occupational Safety and Health Administration (OSHA) 30-Hour General Industry Safety Training

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Metal Cutter

- Highlight your experience and skills in operating and maintaining metal cutting machines.

- Emphasize your ability to interpret technical drawings and specifications accurately.

- Showcase your problem-solving abilities and experience in identifying and correcting machine malfunctions.

- Quantify your accomplishments whenever possible, using specific metrics to demonstrate your impact.

Essential Experience Highlights for a Strong Metal Cutter Resume

- Operate and maintain a variety of metal cutting machines, including CNC plasma cutters, laser cutters, and shear brakes

- Interpret technical drawings and specifications to determine cutting parameters and ensure optimal blade selection

- Set up and calibrate cutting equipment to minimize scrap and maximize yield

- Identify and troubleshoot machine malfunctions proactively to reduce downtime and maintain production efficiency

- Collaborate with engineers and fabricators to develop innovative cutting solutions for challenging design requirements

- Ensure the dimensional accuracy and surface finish of all metal parts through comprehensive quality control

- Train and mentor junior metal cutters to foster a culture of safety and productivity

Frequently Asked Questions (FAQ’s) For Metal Cutter

What are the key skills required for a Metal Cutter?

Key skills include proficiency in operating metal cutting machines (e.g., CNC plasma cutters, laser cutters, shear brakes), interpreting technical drawings and specifications, setting up and calibrating cutting equipment, and troubleshooting machine malfunctions.

What are the career prospects for a Metal Cutter?

Metal Cutters with experience and expertise can advance to roles such as Supervisor, Production Manager, or Quality Control Inspector. Some may also start their own metal fabrication businesses.

What is the work environment like for a Metal Cutter?

Metal Cutters typically work in manufacturing facilities or fabrication shops. The work can be physically demanding and may involve exposure to loud noises, fumes, and hazardous materials. Safety precautions and personal protective equipment are essential.

How can I improve my resume for a Metal Cutter position?

Highlight your experience and skills in metal cutting operations, quantify your accomplishments, obtain industry-recognized certifications, and tailor your resume to each specific job you apply for.

What are the major challenges faced by Metal Cutters?

Challenges include working with different types of metals and alloys, meeting tight deadlines, ensuring precision and accuracy in cutting operations, and staying updated with new technologies and equipment.

What are the safety precautions that Metal Cutters should take?

Wearing appropriate personal protective equipment, following safety guidelines, being aware of potential hazards, and receiving proper training on operating metal cutting machines are crucial for ensuring a safe work environment.

How can I advance my career as a Metal Cutter?

Gaining experience in operating different metal cutting machines, obtaining industry certifications, pursuing further education, and staying updated with technological advancements can enhance your career prospects.