Are you a seasoned Metal Inspector seeking a new career path? Discover our professionally built Metal Inspector Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

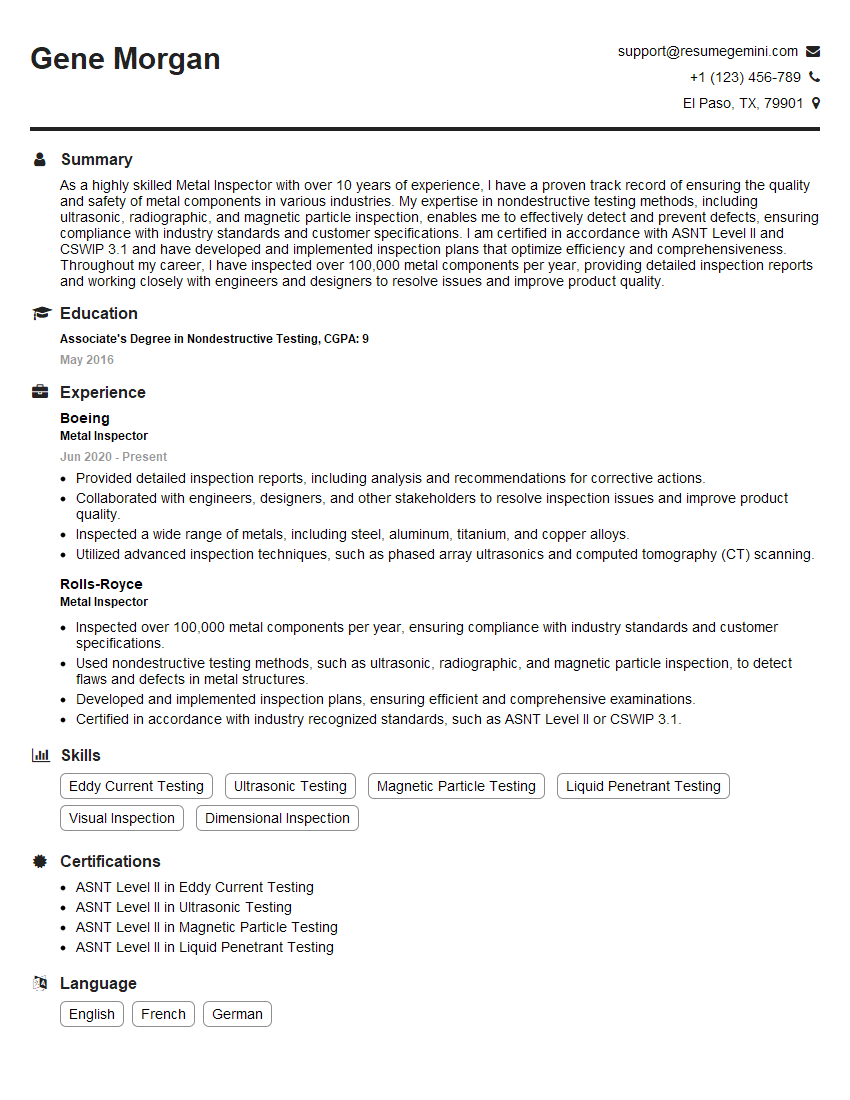

Gene Morgan

Metal Inspector

Summary

As a highly skilled Metal Inspector with over 10 years of experience, I have a proven track record of ensuring the quality and safety of metal components in various industries. My expertise in nondestructive testing methods, including ultrasonic, radiographic, and magnetic particle inspection, enables me to effectively detect and prevent defects, ensuring compliance with industry standards and customer specifications. I am certified in accordance with ASNT Level II and CSWIP 3.1 and have developed and implemented inspection plans that optimize efficiency and comprehensiveness. Throughout my career, I have inspected over 100,000 metal components per year, providing detailed inspection reports and working closely with engineers and designers to resolve issues and improve product quality.

Education

Associate’s Degree in Nondestructive Testing

May 2016

Skills

- Eddy Current Testing

- Ultrasonic Testing

- Magnetic Particle Testing

- Liquid Penetrant Testing

- Visual Inspection

- Dimensional Inspection

Work Experience

Metal Inspector

- Provided detailed inspection reports, including analysis and recommendations for corrective actions.

- Collaborated with engineers, designers, and other stakeholders to resolve inspection issues and improve product quality.

- Inspected a wide range of metals, including steel, aluminum, titanium, and copper alloys.

- Utilized advanced inspection techniques, such as phased array ultrasonics and computed tomography (CT) scanning.

Metal Inspector

- Inspected over 100,000 metal components per year, ensuring compliance with industry standards and customer specifications.

- Used nondestructive testing methods, such as ultrasonic, radiographic, and magnetic particle inspection, to detect flaws and defects in metal structures.

- Developed and implemented inspection plans, ensuring efficient and comprehensive examinations.

- Certified in accordance with industry recognized standards, such as ASNT Level II or CSWIP 3.1.

Certificates

- ASNT Level II in Eddy Current Testing

- ASNT Level II in Ultrasonic Testing

- ASNT Level II in Magnetic Particle Testing

- ASNT Level II in Liquid Penetrant Testing

Languages

- English

- French

- German

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Metal Inspector

- Highlight your certifications and experience in industry-recognized nondestructive testing methods.

- Showcase your ability to interpret inspection results and make recommendations for corrective actions.

- Quantify your accomplishments, such as the number of components inspected or defects detected.

- Emphasize your collaboration skills and ability to work effectively with engineers, designers, and other stakeholders.

- Include keywords related to the metal inspection industry, such as nondestructive testing, quality control, and ASNT.

Essential Experience Highlights for a Strong Metal Inspector Resume

- Inspected metal components using nondestructive testing methods (ultrasonic, radiographic, magnetic particle, etc.) to detect flaws and defects.

- Developed and implemented inspection plans to ensure efficient and comprehensive examinations.

- Analyzed inspection results and provided detailed reports, including recommendations for corrective actions.

- Collaborated with engineers, designers, and other stakeholders to resolve inspection issues and improve product quality.

- Inspected a wide range of metals, including steel, aluminum, titanium, and copper alloys.

- Utilized advanced inspection techniques, such as phased array ultrasonics and computed tomography (CT) scanning.

- Maintained a safe and organized work environment, adhering to all safety protocols.

Frequently Asked Questions (FAQ’s) For Metal Inspector

What are the primary responsibilities of a Metal Inspector?

The primary responsibilities of a Metal Inspector include conducting nondestructive testing on metal components, developing and implementing inspection plans, analyzing inspection results, and providing recommendations for corrective actions.

What qualifications are typically required to become a Metal Inspector?

Typically, a Metal Inspector requires an Associate’s Degree in Nondestructive Testing or a related field, along with certifications in industry-recognized nondestructive testing methods, such as ASNT Level II or CSWIP 3.1.

What are the career prospects for Metal Inspectors?

Metal Inspectors can advance their careers by becoming Senior Inspectors, Quality Control Managers, or even Engineering Consultants. They can also specialize in specific industries, such as aerospace, automotive, or construction.

What are the challenges faced by Metal Inspectors?

Metal Inspectors often work in demanding environments and may be exposed to hazardous materials or conditions. They must also stay up-to-date with the latest inspection techniques and industry standards.

What are the key skills required to excel as a Metal Inspector?

Key skills for Metal Inspectors include attention to detail, analytical thinking, problem-solving abilities, and effective communication skills. They should also have a strong understanding of metallurgy, nondestructive testing methods, and quality control procedures.

What are the earning prospects for Metal Inspectors?

The earning prospects for Metal Inspectors vary depending on experience, qualifications, and industry. According to the U.S. Bureau of Labor Statistics, the median annual salary for Nondestructive Testing Inspectors in May 2021 was $62,390.

What is the job outlook for Metal Inspectors?

The job outlook for Metal Inspectors is expected to grow faster than average over the next few years, driven by increasing demand for quality control in various industries, including aerospace, automotive, and manufacturing.

How can I prepare for a career as a Metal Inspector?

To prepare for a career as a Metal Inspector, you can obtain an Associate’s Degree in Nondestructive Testing or a related field, gain hands-on experience through internships or entry-level positions, and pursue industry-recognized certifications, such as ASNT Level II or CSWIP 3.1.