Are you a seasoned Metal Machinist seeking a new career path? Discover our professionally built Metal Machinist Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

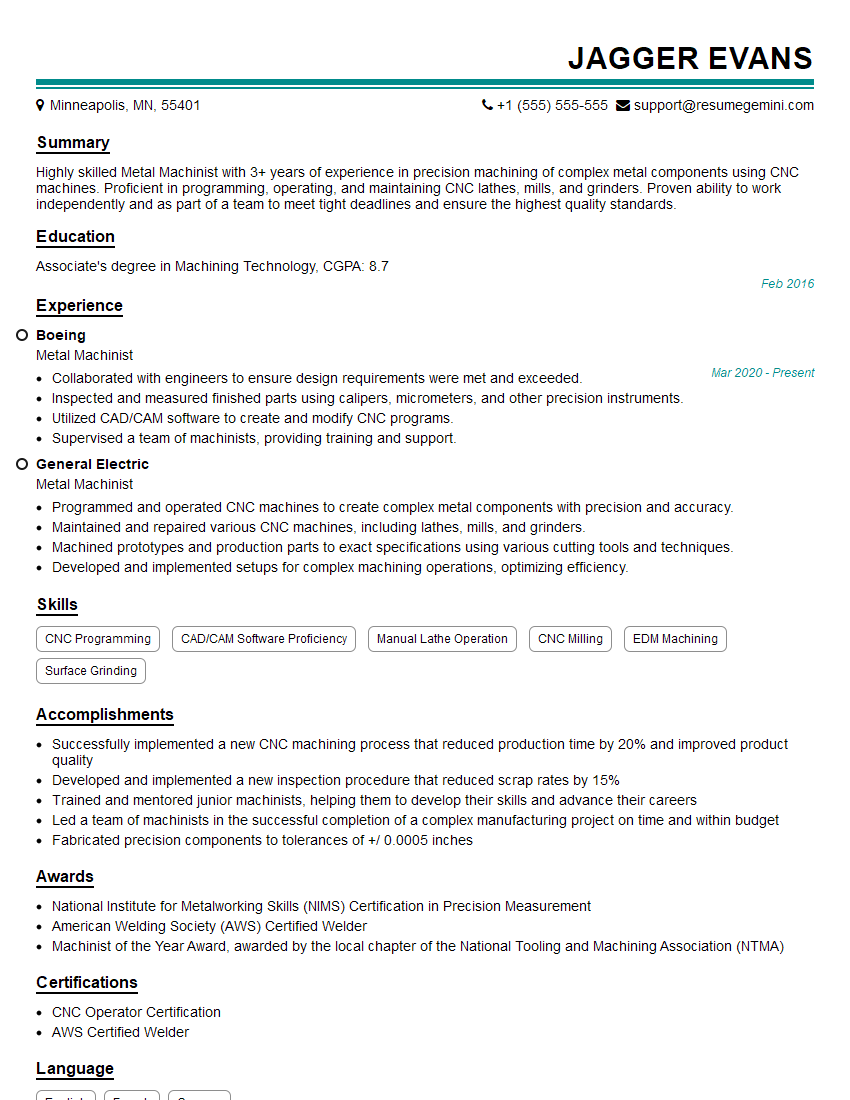

Jagger Evans

Metal Machinist

Summary

Highly skilled Metal Machinist with 3+ years of experience in precision machining of complex metal components using CNC machines. Proficient in programming, operating, and maintaining CNC lathes, mills, and grinders. Proven ability to work independently and as part of a team to meet tight deadlines and ensure the highest quality standards.

Education

Associate’s degree in Machining Technology

February 2016

Skills

- CNC Programming

- CAD/CAM Software Proficiency

- Manual Lathe Operation

- CNC Milling

- EDM Machining

- Surface Grinding

Work Experience

Metal Machinist

- Collaborated with engineers to ensure design requirements were met and exceeded.

- Inspected and measured finished parts using calipers, micrometers, and other precision instruments.

- Utilized CAD/CAM software to create and modify CNC programs.

- Supervised a team of machinists, providing training and support.

Metal Machinist

- Programmed and operated CNC machines to create complex metal components with precision and accuracy.

- Maintained and repaired various CNC machines, including lathes, mills, and grinders.

- Machined prototypes and production parts to exact specifications using various cutting tools and techniques.

- Developed and implemented setups for complex machining operations, optimizing efficiency.

Accomplishments

- Successfully implemented a new CNC machining process that reduced production time by 20% and improved product quality

- Developed and implemented a new inspection procedure that reduced scrap rates by 15%

- Trained and mentored junior machinists, helping them to develop their skills and advance their careers

- Led a team of machinists in the successful completion of a complex manufacturing project on time and within budget

- Fabricated precision components to tolerances of +/ 0.0005 inches

Awards

- National Institute for Metalworking Skills (NIMS) Certification in Precision Measurement

- American Welding Society (AWS) Certified Welder

- Machinist of the Year Award, awarded by the local chapter of the National Tooling and Machining Association (NTMA)

Certificates

- CNC Operator Certification

- AWS Certified Welder

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Metal Machinist

- Highlight your CNC programming and operation skills, emphasizing your proficiency in specific software and machine types.

- Showcase your experience in machining complex parts, demonstrating your ability to handle challenging projects.

- Quantify your accomplishments whenever possible, using specific metrics to demonstrate the impact of your work.

- Tailor your resume to each job application, highlighting the skills and experience that are most relevant to the specific position.

Essential Experience Highlights for a Strong Metal Machinist Resume

- Programmed and operated CNC machines to produce precise and accurate metal components.

- Maintained and repaired various CNC machines, including lathes, mills, and grinders.

- Machined prototypes and production parts to exacting specifications using various cutting tools and techniques.

- Developed and implemented setups for complex machining operations, optimizing efficiency.

- Collaborated with engineers to ensure design requirements were met and exceeded.

- Inspected and measured finished parts using calipers, micrometers, and other precision instruments.

- Utilized CAD/CAM software to create and modify CNC programs.

Frequently Asked Questions (FAQ’s) For Metal Machinist

What are the essential requirements to become a Metal Machinist?

Typically, a high school diploma or equivalent is required, along with an associate’s degree or certificate in machining technology. Additional training and experience in CNC programming and operation are highly beneficial.

What are the primary job duties of a Metal Machinist?

Metal Machinists use CNC machines and other tools to fabricate, assemble, and repair metal parts and components. They typically work in manufacturing environments, often specializing in a particular type of machining, such as turning, milling, or grinding.

What are the career prospects for Metal Machinists?

Metal Machinists are in high demand due to the growing need for skilled workers in the manufacturing sector. The job outlook is expected to remain positive over the next decade, with opportunities for advancement to supervisory or management roles.

What are the key skills and qualities of a successful Metal Machinist?

Successful Metal Machinists possess strong technical skills in CNC programming and operation, as well as a solid understanding of machining principles. They are also typically detail-oriented, have good problem-solving abilities, and are able to work independently and as part of a team.

What are the typical working conditions for Metal Machinists?

Metal Machinists typically work in manufacturing environments, which can be noisy and involve exposure to hazardous materials. They may also need to work overtime or on weekends to meet production deadlines.

What are the potential hazards associated with metal machining?

Metal Machinists may be exposed to various hazards, including sharp tools, rotating machinery, and hazardous chemicals. They must adhere to safety regulations and wear appropriate protective gear to minimize risks.

What are the differences between manual and CNC machining?

Manual machining involves operating machines manually, while CNC machining uses computer-controlled machines. CNC machining offers greater precision, efficiency, and repeatability, making it suitable for complex and high-volume production.

What are the latest trends in metal machining?

The metal machining industry is witnessing advancements in technologies such as additive manufacturing (3D printing), automation, and digitalization. These advancements are transforming production processes and creating new opportunities for Metal Machinists.