Are you a seasoned Metal Mold Maker seeking a new career path? Discover our professionally built Metal Mold Maker Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

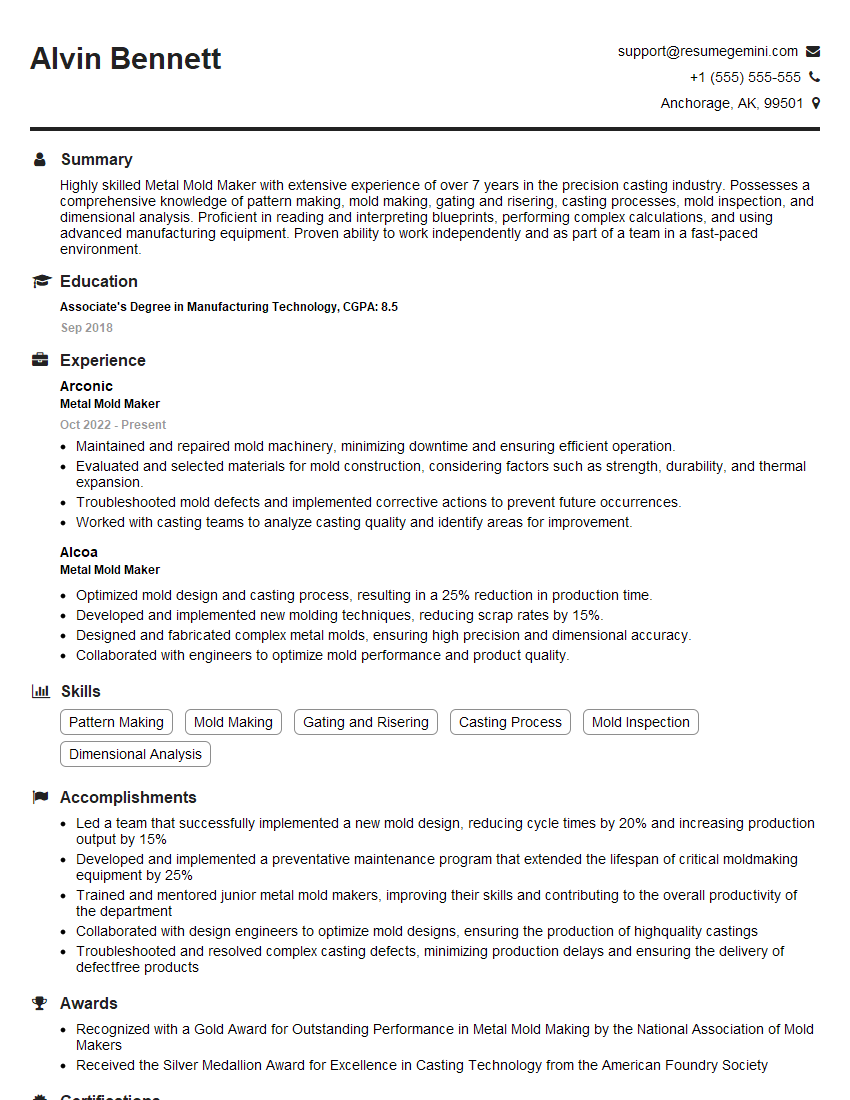

Alvin Bennett

Metal Mold Maker

Summary

Highly skilled Metal Mold Maker with extensive experience of over 7 years in the precision casting industry. Possesses a comprehensive knowledge of pattern making, mold making, gating and risering, casting processes, mold inspection, and dimensional analysis. Proficient in reading and interpreting blueprints, performing complex calculations, and using advanced manufacturing equipment. Proven ability to work independently and as part of a team in a fast-paced environment.

Education

Associate’s Degree in Manufacturing Technology

September 2018

Skills

- Pattern Making

- Mold Making

- Gating and Risering

- Casting Process

- Mold Inspection

- Dimensional Analysis

Work Experience

Metal Mold Maker

- Maintained and repaired mold machinery, minimizing downtime and ensuring efficient operation.

- Evaluated and selected materials for mold construction, considering factors such as strength, durability, and thermal expansion.

- Troubleshooted mold defects and implemented corrective actions to prevent future occurrences.

- Worked with casting teams to analyze casting quality and identify areas for improvement.

Metal Mold Maker

- Optimized mold design and casting process, resulting in a 25% reduction in production time.

- Developed and implemented new molding techniques, reducing scrap rates by 15%.

- Designed and fabricated complex metal molds, ensuring high precision and dimensional accuracy.

- Collaborated with engineers to optimize mold performance and product quality.

Accomplishments

- Led a team that successfully implemented a new mold design, reducing cycle times by 20% and increasing production output by 15%

- Developed and implemented a preventative maintenance program that extended the lifespan of critical moldmaking equipment by 25%

- Trained and mentored junior metal mold makers, improving their skills and contributing to the overall productivity of the department

- Collaborated with design engineers to optimize mold designs, ensuring the production of highquality castings

- Troubleshooted and resolved complex casting defects, minimizing production delays and ensuring the delivery of defectfree products

Awards

- Recognized with a Gold Award for Outstanding Performance in Metal Mold Making by the National Association of Mold Makers

- Received the Silver Medallion Award for Excellence in Casting Technology from the American Foundry Society

Certificates

- Certified Metal Mold Maker (CMMM)

- Certified Patternmaker (CPM)

- ISO 9001 Lead Auditor

- OSHA Safety Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Metal Mold Maker

- Highlight your skills in pattern making, mold making, and casting processes, as these are crucial for Metal Mold Makers.

- Quantify your accomplishments with specific numbers and metrics whenever possible.

- Showcase your ability to work independently and as part of a team.

- Demonstrate your understanding of industry standards and best practices related to metal mold making.

Essential Experience Highlights for a Strong Metal Mold Maker Resume

- Designed and fabricated metal molds using advanced computer-aided design (CAD) software.

- Constructed and maintained molds for casting various metal parts, ensuring dimensional accuracy and surface finish.

- Developed and implemented gating and risering systems to optimize casting quality and minimize defects.

- Conducted in-process and final inspections of molds to ensure compliance with specifications and quality standards.

- Analyzed casting defects to identify root causes and implemented corrective actions.

- Performed dimensional analysis using coordinate measuring machines (CMMs) to verify mold accuracy.

Frequently Asked Questions (FAQ’s) For Metal Mold Maker

What are the primary responsibilities of a Metal Mold Maker?

Metal Mold Makers are responsible for designing, fabricating, and maintaining molds used in the casting process. They work closely with engineers and other manufacturing professionals to ensure that the molds meet the required specifications and produce high-quality castings.

What skills are essential for a successful Metal Mold Maker?

Essential skills for a Metal Mold Maker include pattern making, mold making, gating and risering, casting processes, mold inspection, dimensional analysis, and proficiency in using CAD software and manufacturing equipment.

What are the career prospects for Metal Mold Makers?

Metal Mold Makers can advance their careers by specializing in a particular area of mold making, such as precision casting or investment casting. They can also move into supervisory or management roles, or become self-employed.

What is the job outlook for Metal Mold Makers?

The job outlook for Metal Mold Makers is expected to be favorable in the coming years due to the increasing demand for skilled manufacturing professionals. Industries such as aerospace, automotive, and medical devices rely heavily on Metal Mold Makers to produce high-quality castings.

What is the average salary for Metal Mold Makers?

The average salary for Metal Mold Makers varies depending on experience, location, and industry. According to the U.S. Bureau of Labor Statistics, the median annual salary for Mold Makers and Patternmakers was $48,660 in May 2021.

What are the educational requirements to become a Metal Mold Maker?

Most Metal Mold Makers have an associate’s degree in manufacturing technology or a related field. Some employers may also require candidates to have experience in a machine shop or foundry.