Are you a seasoned Metal Pattern Maker seeking a new career path? Discover our professionally built Metal Pattern Maker Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

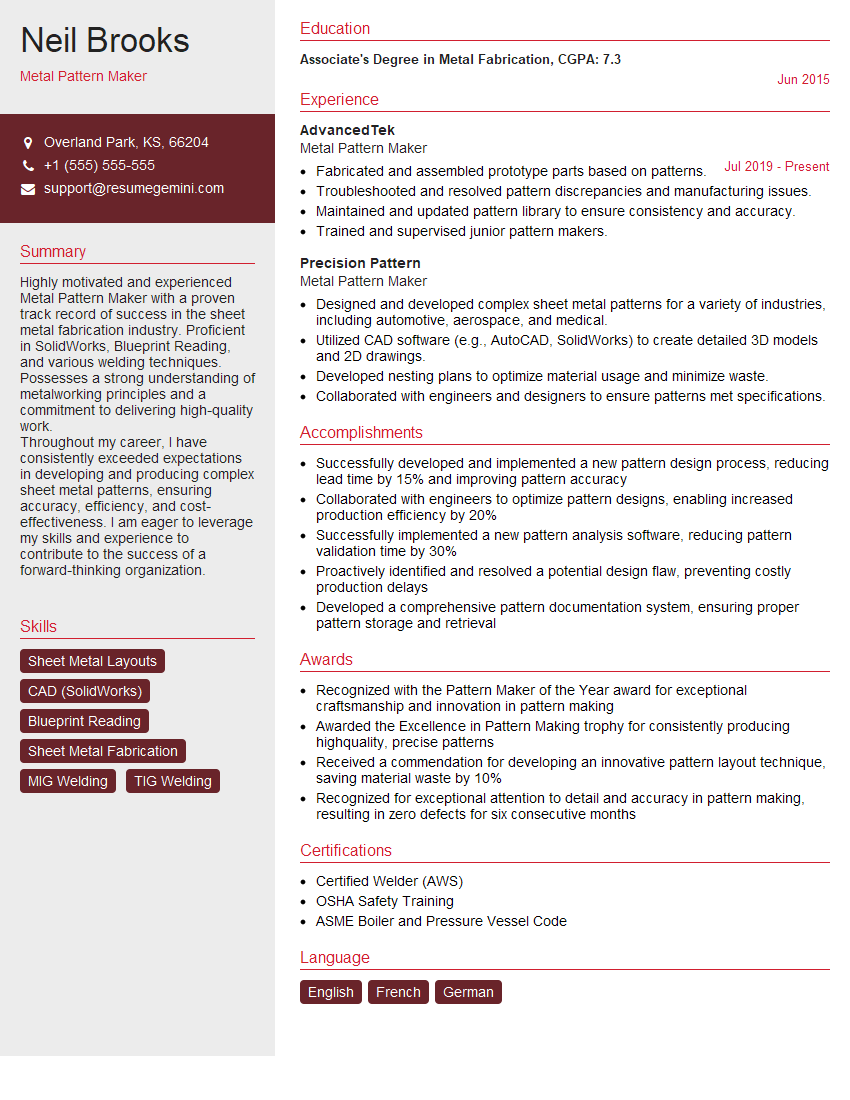

Neil Brooks

Metal Pattern Maker

Summary

Highly motivated and experienced Metal Pattern Maker with a proven track record of success in the sheet metal fabrication industry. Proficient in SolidWorks, Blueprint Reading, and various welding techniques. Possesses a strong understanding of metalworking principles and a commitment to delivering high-quality work.

Throughout my career, I have consistently exceeded expectations in developing and producing complex sheet metal patterns, ensuring accuracy, efficiency, and cost-effectiveness. I am eager to leverage my skills and experience to contribute to the success of a forward-thinking organization.

Education

Associate’s Degree in Metal Fabrication

June 2015

Skills

- Sheet Metal Layouts

- CAD (SolidWorks)

- Blueprint Reading

- Sheet Metal Fabrication

- MIG Welding

- TIG Welding

Work Experience

Metal Pattern Maker

- Fabricated and assembled prototype parts based on patterns.

- Troubleshooted and resolved pattern discrepancies and manufacturing issues.

- Maintained and updated pattern library to ensure consistency and accuracy.

- Trained and supervised junior pattern makers.

Metal Pattern Maker

- Designed and developed complex sheet metal patterns for a variety of industries, including automotive, aerospace, and medical.

- Utilized CAD software (e.g., AutoCAD, SolidWorks) to create detailed 3D models and 2D drawings.

- Developed nesting plans to optimize material usage and minimize waste.

- Collaborated with engineers and designers to ensure patterns met specifications.

Accomplishments

- Successfully developed and implemented a new pattern design process, reducing lead time by 15% and improving pattern accuracy

- Collaborated with engineers to optimize pattern designs, enabling increased production efficiency by 20%

- Successfully implemented a new pattern analysis software, reducing pattern validation time by 30%

- Proactively identified and resolved a potential design flaw, preventing costly production delays

- Developed a comprehensive pattern documentation system, ensuring proper pattern storage and retrieval

Awards

- Recognized with the Pattern Maker of the Year award for exceptional craftsmanship and innovation in pattern making

- Awarded the Excellence in Pattern Making trophy for consistently producing highquality, precise patterns

- Received a commendation for developing an innovative pattern layout technique, saving material waste by 10%

- Recognized for exceptional attention to detail and accuracy in pattern making, resulting in zero defects for six consecutive months

Certificates

- Certified Welder (AWS)

- OSHA Safety Training

- ASME Boiler and Pressure Vessel Code

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Metal Pattern Maker

- Highlight your proficiency in SolidWorks and other relevant software, as it is essential for pattern development.

- Showcase your ability to interpret complex blueprints and engineering drawings accurately.

- Emphasize your skills in MIG and TIG welding, as they are critical for sheet metal fabrication.

- Demonstrate your commitment to quality by highlighting your experience in performing quality control inspections.

Essential Experience Highlights for a Strong Metal Pattern Maker Resume

- Develop and create sheet metal patterns using SolidWorks and other industry-standard software.

- Interpret and analyze blueprints and engineering drawings to ensure accurate pattern development.

- Utilize MIG and TIG welding techniques to fabricate sheet metal components and assemblies.

- Perform quality control inspections to ensure compliance with specifications and standards.

- Collaborate with engineers and production teams to optimize manufacturing processes.

- Stay up-to-date on industry trends and best practices in sheet metal fabrication.

- Participate in continuous improvement initiatives to enhance productivity and efficiency.

Frequently Asked Questions (FAQ’s) For Metal Pattern Maker

What is the role of a Metal Pattern Maker?

A Metal Pattern Maker is responsible for creating sheet metal patterns used in the fabrication of various metal products. They interpret blueprints, develop patterns using software, and use welding techniques to produce accurate and high-quality components.

What are the essential skills required for this role?

Essential skills include proficiency in SolidWorks or other CAD software, Blueprint Reading, MIG and TIG welding, sheet metal fabrication techniques, and quality control procedures.

What industries employ Metal Pattern Makers?

Metal Pattern Makers are employed in various industries, including automotive, aerospace, construction, and manufacturing.

What is the job outlook for Metal Pattern Makers?

The job outlook for Metal Pattern Makers is expected to be positive due to the increasing demand for skilled workers in the sheet metal fabrication industry.

What is the average salary for a Metal Pattern Maker?

The average salary for a Metal Pattern Maker varies depending on experience, location, and industry, but it typically ranges from $25,000 to $60,000 annually.

What are the benefits of working as a Metal Pattern Maker?

Benefits include job stability, opportunities for advancement, competitive salaries, and the satisfaction of working in a skilled trade.

What are the challenges faced by Metal Pattern Makers?

Challenges include working with sharp materials and heavy equipment, exposure to fumes and noise, and the need to meet tight deadlines.