Are you a seasoned Metal Plater seeking a new career path? Discover our professionally built Metal Plater Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

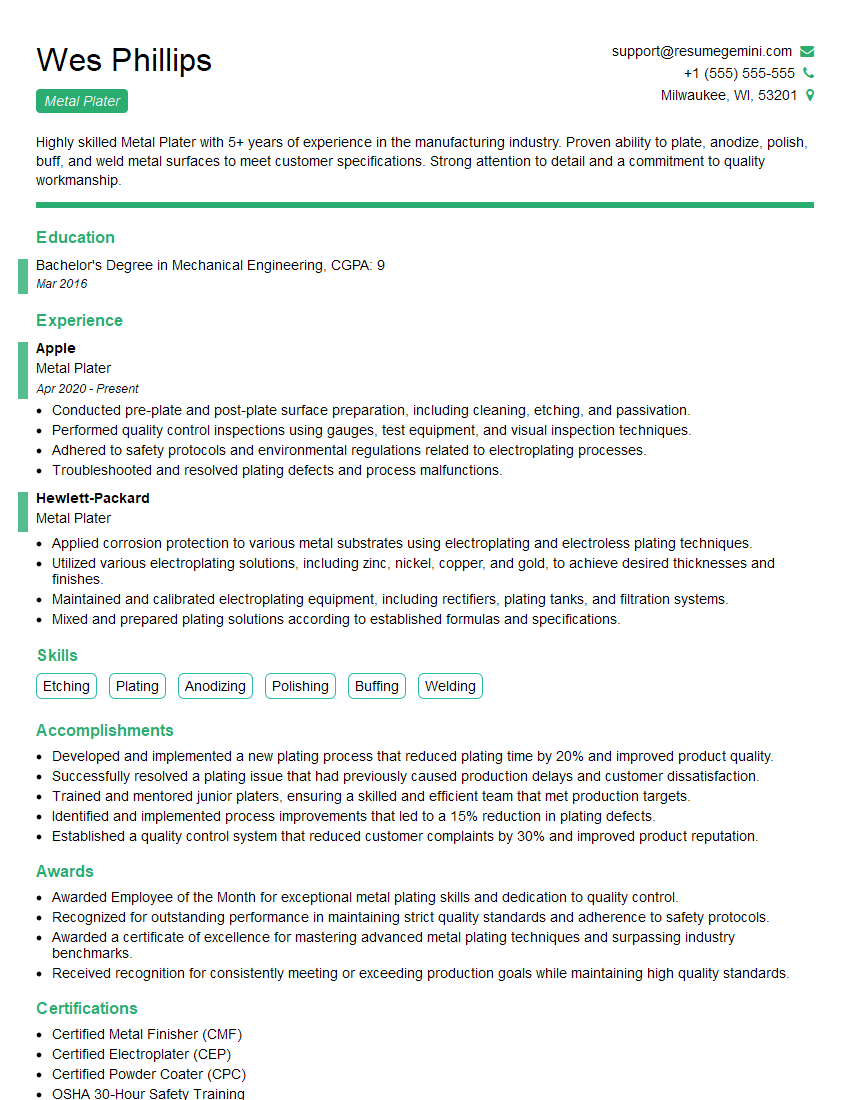

Wes Phillips

Metal Plater

Summary

Highly skilled Metal Plater with 5+ years of experience in the manufacturing industry. Proven ability to plate, anodize, polish, buff, and weld metal surfaces to meet customer specifications. Strong attention to detail and a commitment to quality workmanship.

Education

Bachelor’s Degree in Mechanical Engineering

March 2016

Skills

- Etching

- Plating

- Anodizing

- Polishing

- Buffing

- Welding

Work Experience

Metal Plater

- Conducted pre-plate and post-plate surface preparation, including cleaning, etching, and passivation.

- Performed quality control inspections using gauges, test equipment, and visual inspection techniques.

- Adhered to safety protocols and environmental regulations related to electroplating processes.

- Troubleshooted and resolved plating defects and process malfunctions.

Metal Plater

- Applied corrosion protection to various metal substrates using electroplating and electroless plating techniques.

- Utilized various electroplating solutions, including zinc, nickel, copper, and gold, to achieve desired thicknesses and finishes.

- Maintained and calibrated electroplating equipment, including rectifiers, plating tanks, and filtration systems.

- Mixed and prepared plating solutions according to established formulas and specifications.

Accomplishments

- Developed and implemented a new plating process that reduced plating time by 20% and improved product quality.

- Successfully resolved a plating issue that had previously caused production delays and customer dissatisfaction.

- Trained and mentored junior platers, ensuring a skilled and efficient team that met production targets.

- Identified and implemented process improvements that led to a 15% reduction in plating defects.

- Established a quality control system that reduced customer complaints by 30% and improved product reputation.

Awards

- Awarded Employee of the Month for exceptional metal plating skills and dedication to quality control.

- Recognized for outstanding performance in maintaining strict quality standards and adherence to safety protocols.

- Awarded a certificate of excellence for mastering advanced metal plating techniques and surpassing industry benchmarks.

- Received recognition for consistently meeting or exceeding production goals while maintaining high quality standards.

Certificates

- Certified Metal Finisher (CMF)

- Certified Electroplater (CEP)

- Certified Powder Coater (CPC)

- OSHA 30-Hour Safety Training

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Metal Plater

- Highlight your skills and experience in your resume objective statement.

- Use keywords from the job description in your resume.

- Quantify your accomplishments whenever possible.

- Proofread your resume carefully before submitting it.

- Get feedback on your resume from a friend or family member.

Essential Experience Highlights for a Strong Metal Plater Resume

- Plate metal surfaces using a variety of techniques, including electroplating, electroless plating, and vapor deposition

- Anodize metal surfaces to improve their corrosion resistance and wear resistance

- Polish and buff metal surfaces to achieve a desired finish

- Weld metal components using a variety of welding techniques, including TIG welding, MIG welding, and spot welding

- Etch metal surfaces to create patterns or designs

- Maintain and repair plating equipment

- Follow all safety procedures and regulations

Frequently Asked Questions (FAQ’s) For Metal Plater

What is the job outlook for Metal Platers?

The job outlook for Metal Platers is expected to be good over the next few years. The demand for Metal Platers is expected to increase as the manufacturing industry continues to grow.

What are the educational requirements for Metal Platers?

Most Metal Platers have a high school diploma or equivalent. Some employers may require Metal Platers to have a post-secondary degree in a related field, such as chemistry or engineering.

What are the salary expectations for Metal Platers?

The salary expectations for Metal Platers vary depending on their experience, skills, and location. According to the U.S. Bureau of Labor Statistics, the median annual salary for Metal Platers was $46,090 in May 2021.

What are the working conditions for Metal Platers?

Metal Platers typically work in factories or other industrial settings. They may be exposed to hazardous chemicals and fumes, and they may have to work in uncomfortable positions for long periods of time.

What are the career advancement opportunities for Metal Platers?

Metal Platers can advance their careers by gaining experience and developing new skills. They may become supervisors or managers, or they may specialize in a particular area of metal plating.

What are the job duties of Metal Platers?

Metal Platers are responsible for plating metal surfaces with a variety of materials, including metals, plastics, and ceramics. They may also be responsible for polishing, buffing, and welding metal surfaces.

What are the skills and abilities required to be a Metal Plater?

Metal Platers need to have good hand-eye coordination and manual dexterity. They also need to be able to work independently and follow instructions carefully.