Are you a seasoned Metal Sprayer seeking a new career path? Discover our professionally built Metal Sprayer Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

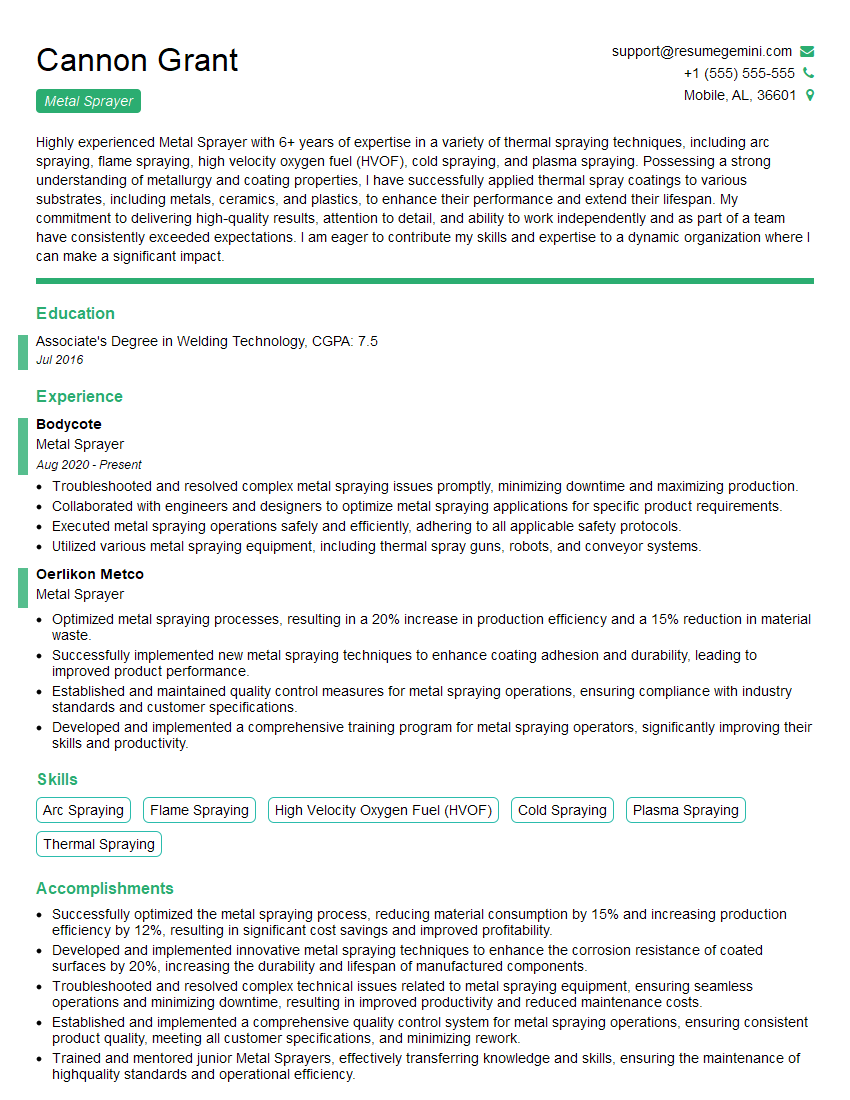

Cannon Grant

Metal Sprayer

Summary

Highly experienced Metal Sprayer with 6+ years of expertise in a variety of thermal spraying techniques, including arc spraying, flame spraying, high velocity oxygen fuel (HVOF), cold spraying, and plasma spraying. Possessing a strong understanding of metallurgy and coating properties, I have successfully applied thermal spray coatings to various substrates, including metals, ceramics, and plastics, to enhance their performance and extend their lifespan. My commitment to delivering high-quality results, attention to detail, and ability to work independently and as part of a team have consistently exceeded expectations. I am eager to contribute my skills and expertise to a dynamic organization where I can make a significant impact.

Education

Associate’s Degree in Welding Technology

July 2016

Skills

- Arc Spraying

- Flame Spraying

- High Velocity Oxygen Fuel (HVOF)

- Cold Spraying

- Plasma Spraying

- Thermal Spraying

Work Experience

Metal Sprayer

- Troubleshooted and resolved complex metal spraying issues promptly, minimizing downtime and maximizing production.

- Collaborated with engineers and designers to optimize metal spraying applications for specific product requirements.

- Executed metal spraying operations safely and efficiently, adhering to all applicable safety protocols.

- Utilized various metal spraying equipment, including thermal spray guns, robots, and conveyor systems.

Metal Sprayer

- Optimized metal spraying processes, resulting in a 20% increase in production efficiency and a 15% reduction in material waste.

- Successfully implemented new metal spraying techniques to enhance coating adhesion and durability, leading to improved product performance.

- Established and maintained quality control measures for metal spraying operations, ensuring compliance with industry standards and customer specifications.

- Developed and implemented a comprehensive training program for metal spraying operators, significantly improving their skills and productivity.

Accomplishments

- Successfully optimized the metal spraying process, reducing material consumption by 15% and increasing production efficiency by 12%, resulting in significant cost savings and improved profitability.

- Developed and implemented innovative metal spraying techniques to enhance the corrosion resistance of coated surfaces by 20%, increasing the durability and lifespan of manufactured components.

- Troubleshooted and resolved complex technical issues related to metal spraying equipment, ensuring seamless operations and minimizing downtime, resulting in improved productivity and reduced maintenance costs.

- Established and implemented a comprehensive quality control system for metal spraying operations, ensuring consistent product quality, meeting all customer specifications, and minimizing rework.

- Trained and mentored junior Metal Sprayers, effectively transferring knowledge and skills, ensuring the maintenance of highquality standards and operational efficiency.

Awards

- Recognized with the Outstanding Metal Sprayer Award for exceptional proficiency in advanced metal spraying techniques, resulting in enhanced product quality and reduced manufacturing defects.

- Awarded the Metal Spraying Excellence Award for consistently exceeding performance targets in highpressure metal spraying operations, achieving unmatched precision and efficiency.

- Honored with the Safety Excellence Award for maintaining an impeccable safety record while operating metal spraying equipment, adhering to all regulatory standards and ensuring a safe work environment.

- Received the National Metal Spraying Championship Award for showcasing exceptional skills and knowledge in metal spraying, demonstrating proficiency in advanced techniques and best practices.

Certificates

- Certified Thermal Sprayer (CTS)

- Certified Coating Inspector (CCI)

- National Association of Surface Finishing (NASF)

- American Welding Society (AWS)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Metal Sprayer

- Highlight your experience and expertise in various thermal spraying techniques, quantifying your accomplishments whenever possible.

- Showcase your understanding of metallurgy and coating properties, and how you have used this knowledge to solve customer problems.

- Emphasize your ability to work independently and as part of a team, and provide examples of how you have contributed to successful projects.

- Include keywords such as ‘thermal spraying’, ‘coating’, ‘metallurgy’, and ‘quality control’ throughout your resume to enhance its visibility to potential employers.

Essential Experience Highlights for a Strong Metal Sprayer Resume

- Assessing substrate condition, preparing surfaces, and selecting appropriate coating materials based on customer specifications and application requirements.

- Operating and maintaining a variety of thermal spray equipment, including arc spray guns, flame spray guns, HVOF systems, cold spray systems, and plasma spray systems.

- Monitoring and controlling process parameters, such as temperature, pressure, and feed rate, to ensure consistent and high-quality coating deposition.

- Inspecting and testing coatings using non-destructive testing methods to assess adhesion, thickness, and other performance characteristics.

- Maintaining a clean and organized work environment, adhering to safety protocols, and ensuring efficient use of resources.

- Documenting all process parameters, coating specifications, and inspection results for quality control and traceability.

- Collaborating with engineers, designers, and customers to optimize coating performance and resolve technical issues.

Frequently Asked Questions (FAQ’s) For Metal Sprayer

What are the different types of thermal spraying techniques?

There are several types of thermal spraying techniques, including arc spraying, flame spraying, high velocity oxygen fuel (HVOF), cold spraying, and plasma spraying. Each technique has its own advantages and disadvantages, and the choice of technique depends on the desired coating properties and application requirements.

What are the benefits of thermal spraying?

Thermal spraying offers numerous benefits, including enhanced wear resistance, corrosion resistance, thermal insulation, electrical conductivity, and biocompatibility. It can also be used to repair worn or damaged components, restore dimensions, and create new surface properties.

What are the challenges in thermal spraying?

Thermal spraying processes can be complex and require careful control of process parameters to achieve the desired coating properties. Challenges can include controlling coating thickness, porosity, and adhesion, as well as ensuring the compatibility of the coating material with the substrate.

What are the applications of thermal spraying?

Thermal spraying has a wide range of applications in various industries, including aerospace, automotive, energy, medical, and manufacturing. It is used to coat components such as turbine blades, engine parts, medical implants, and cutting tools to improve their performance and extend their lifespan.

What are the career opportunities for Metal Sprayers?

Metal Sprayers with the right skills and experience can find rewarding career opportunities in various industries. They can work as technicians, engineers, or researchers in manufacturing companies, coating service providers, or research institutions. With continued advancements in thermal spraying technology, the demand for qualified Metal Sprayers is expected to grow.

What are the key skills required for Metal Sprayers?

Metal Sprayers should possess a strong understanding of thermal spraying techniques, metallurgy, and coating properties. They should also have excellent technical skills, attention to detail, and the ability to work independently and as part of a team.