Are you a seasoned Metal Wire Coating Operator seeking a new career path? Discover our professionally built Metal Wire Coating Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

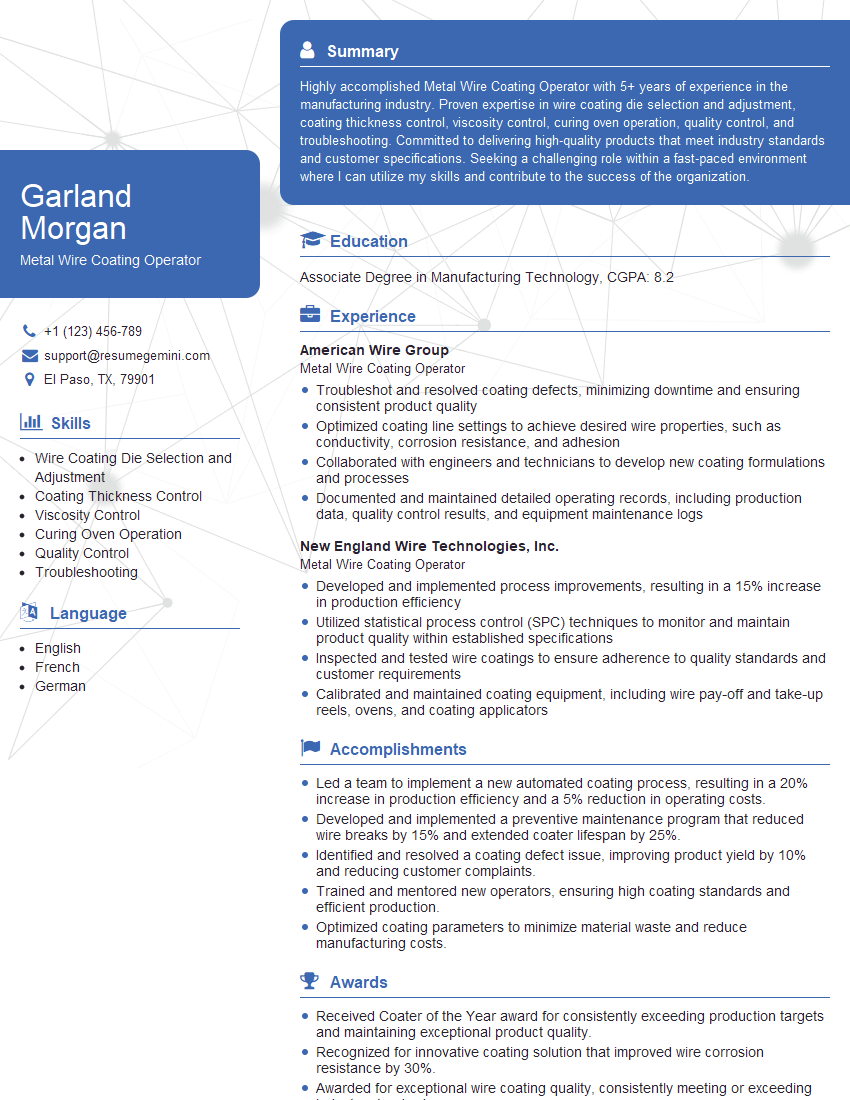

Garland Morgan

Metal Wire Coating Operator

Summary

Highly accomplished Metal Wire Coating Operator with 5+ years of experience in the manufacturing industry. Proven expertise in wire coating die selection and adjustment, coating thickness control, viscosity control, curing oven operation, quality control, and troubleshooting. Committed to delivering high-quality products that meet industry standards and customer specifications. Seeking a challenging role within a fast-paced environment where I can utilize my skills and contribute to the success of the organization.

Education

Associate Degree in Manufacturing Technology

May 2017

Skills

- Wire Coating Die Selection and Adjustment

- Coating Thickness Control

- Viscosity Control

- Curing Oven Operation

- Quality Control

- Troubleshooting

Work Experience

Metal Wire Coating Operator

- Troubleshot and resolved coating defects, minimizing downtime and ensuring consistent product quality

- Optimized coating line settings to achieve desired wire properties, such as conductivity, corrosion resistance, and adhesion

- Collaborated with engineers and technicians to develop new coating formulations and processes

- Documented and maintained detailed operating records, including production data, quality control results, and equipment maintenance logs

Metal Wire Coating Operator

- Developed and implemented process improvements, resulting in a 15% increase in production efficiency

- Utilized statistical process control (SPC) techniques to monitor and maintain product quality within established specifications

- Inspected and tested wire coatings to ensure adherence to quality standards and customer requirements

- Calibrated and maintained coating equipment, including wire pay-off and take-up reels, ovens, and coating applicators

Accomplishments

- Led a team to implement a new automated coating process, resulting in a 20% increase in production efficiency and a 5% reduction in operating costs.

- Developed and implemented a preventive maintenance program that reduced wire breaks by 15% and extended coater lifespan by 25%.

- Identified and resolved a coating defect issue, improving product yield by 10% and reducing customer complaints.

- Trained and mentored new operators, ensuring high coating standards and efficient production.

- Optimized coating parameters to minimize material waste and reduce manufacturing costs.

Awards

- Received Coater of the Year award for consistently exceeding production targets and maintaining exceptional product quality.

- Recognized for innovative coating solution that improved wire corrosion resistance by 30%.

- Awarded for exceptional wire coating quality, consistently meeting or exceeding industry standards.

- Recognized for outstanding safety record, maintaining a clean and accidentfree work environment.

Certificates

- Certified Wire Coating Operator (CWCO)

- OSHA 10-Hour General Industry Safety

- OSHA 30-Hour General Industry Safety

- NFPA 70E Standard for Electrical Safety in the Workplace

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Metal Wire Coating Operator

- Highlight your experience in metal wire coating and any specific techniques or technologies you are proficient in.

- Quantify your accomplishments whenever possible. For instance, mention the percentage improvement in coating thickness control or the number of defects reduced.

- Showcase your knowledge of quality control standards and industry best practices.

- Demonstrate your commitment to safety and a clean work environment.

- Consider including any certifications or training related to metal wire coating.

Essential Experience Highlights for a Strong Metal Wire Coating Operator Resume

- Selected and adjusted wire coating dies to achieve desired coating thickness and quality.

- Controlled coating thickness within specified tolerances using precision instruments and techniques.

- Monitored and adjusted viscosity of coating materials to ensure optimal application.

- Operated and maintained curing ovens to cure coated wires according to established parameters.

- Conducted quality control inspections to ensure coated wires met specifications, using gauges, micrometers, and other testing equipment.

- Troubleshooted and resolved issues related to coating processes, ensuring smooth production flow.

- Followed safety protocols and maintained a clean and organized work environment.

Frequently Asked Questions (FAQ’s) For Metal Wire Coating Operator

What are the primary duties of a Metal Wire Coating Operator?

The primary duties of a Metal Wire Coating Operator include selecting and adjusting wire coating dies, controlling coating thickness, monitoring viscosity, operating curing ovens, conducting quality control inspections, troubleshooting issues, and maintaining a safe and organized work environment.

What skills are essential for Metal Wire Coating Operators?

Essential skills for Metal Wire Coating Operators include wire coating die selection and adjustment, coating thickness control, viscosity control, curing oven operation, quality control, and troubleshooting.

What industries employ Metal Wire Coating Operators?

Metal Wire Coating Operators find employment in various industries, such as automotive, electrical, and construction, where coated wires are used in electrical wiring, cables, and other applications.

What are the educational requirements for Metal Wire Coating Operators?

While formal education requirements may vary, many Metal Wire Coating Operators hold an Associate Degree in Manufacturing Technology or a related field.

What is the job outlook for Metal Wire Coating Operators?

The job outlook for Metal Wire Coating Operators is expected to be stable, driven by the growing demand for coated wires in various industries.

What are the earning prospects for Metal Wire Coating Operators?

Earning prospects for Metal Wire Coating Operators vary depending on experience, skills, and location. However, the median annual salary is around $45,000.

What are the career advancement opportunities for Metal Wire Coating Operators?

With experience and additional training, Metal Wire Coating Operators can advance to supervisory or management positions within the manufacturing industry.