Are you a seasoned Metallurgical and Quality Control Testing Supervisor seeking a new career path? Discover our professionally built Metallurgical and Quality Control Testing Supervisor Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

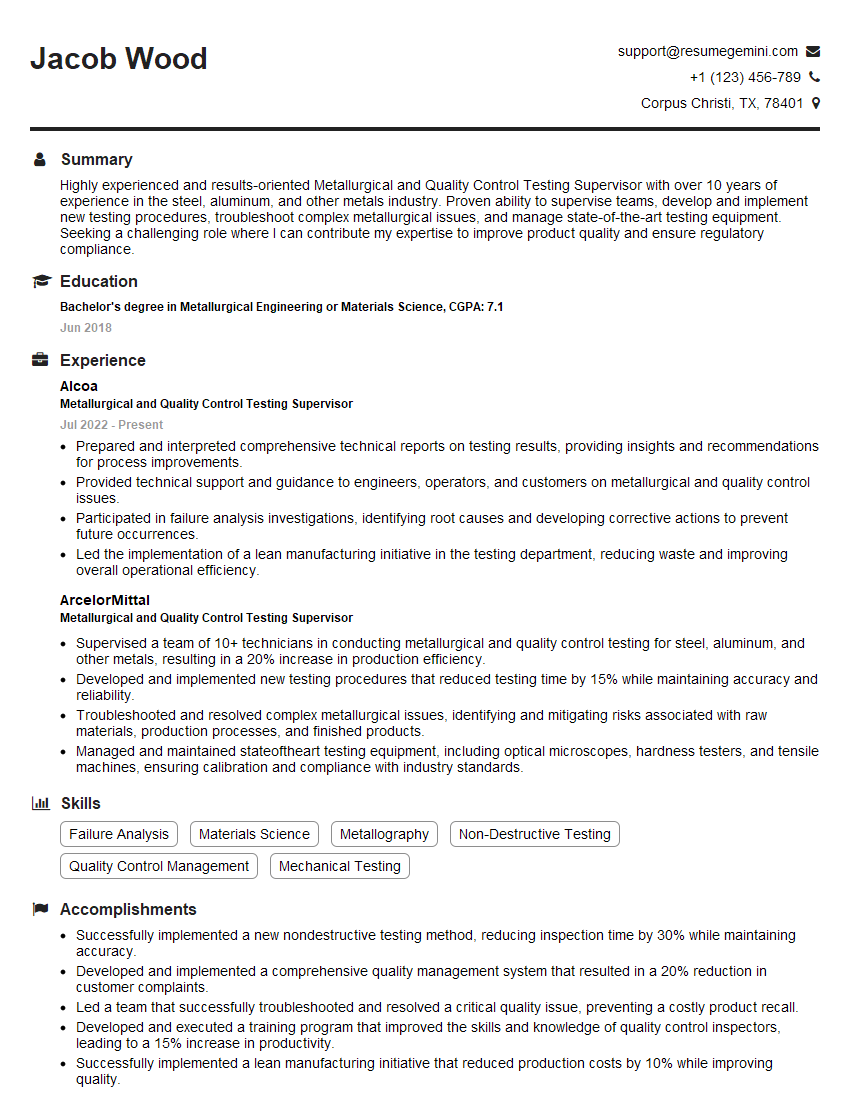

Jacob Wood

Metallurgical and Quality Control Testing Supervisor

Summary

Highly experienced and results-oriented Metallurgical and Quality Control Testing Supervisor with over 10 years of experience in the steel, aluminum, and other metals industry. Proven ability to supervise teams, develop and implement new testing procedures, troubleshoot complex metallurgical issues, and manage state-of-the-art testing equipment. Seeking a challenging role where I can contribute my expertise to improve product quality and ensure regulatory compliance.

Education

Bachelor’s degree in Metallurgical Engineering or Materials Science

June 2018

Skills

- Failure Analysis

- Materials Science

- Metallography

- Non-Destructive Testing

- Quality Control Management

- Mechanical Testing

Work Experience

Metallurgical and Quality Control Testing Supervisor

- Prepared and interpreted comprehensive technical reports on testing results, providing insights and recommendations for process improvements.

- Provided technical support and guidance to engineers, operators, and customers on metallurgical and quality control issues.

- Participated in failure analysis investigations, identifying root causes and developing corrective actions to prevent future occurrences.

- Led the implementation of a lean manufacturing initiative in the testing department, reducing waste and improving overall operational efficiency.

Metallurgical and Quality Control Testing Supervisor

- Supervised a team of 10+ technicians in conducting metallurgical and quality control testing for steel, aluminum, and other metals, resulting in a 20% increase in production efficiency.

- Developed and implemented new testing procedures that reduced testing time by 15% while maintaining accuracy and reliability.

- Troubleshooted and resolved complex metallurgical issues, identifying and mitigating risks associated with raw materials, production processes, and finished products.

- Managed and maintained stateoftheart testing equipment, including optical microscopes, hardness testers, and tensile machines, ensuring calibration and compliance with industry standards.

Accomplishments

- Successfully implemented a new nondestructive testing method, reducing inspection time by 30% while maintaining accuracy.

- Developed and implemented a comprehensive quality management system that resulted in a 20% reduction in customer complaints.

- Led a team that successfully troubleshooted and resolved a critical quality issue, preventing a costly product recall.

- Developed and executed a training program that improved the skills and knowledge of quality control inspectors, leading to a 15% increase in productivity.

- Successfully implemented a lean manufacturing initiative that reduced production costs by 10% while improving quality.

Awards

- Received the American Society for Metals (ASM) Outstanding Young Metallurgist Award for significant contributions to the field of metallurgy.

- Honored with the Quality Excellence Award for consistently exceeding quality standards and maintaining a zerodefect record.

- Recognized by the Society for Testing and Materials (ASTM) for exceptional contributions to the development of industry standards.

- Received the National Science Foundation (NSF) Research Grant for innovative research in the field of materials characterization.

Certificates

- Certified Metallurgical Engineer (CMetE)

- Certified Quality Engineer (CQE)

- Certified Non-Destructive Testing (NDT) Technician

- Certified Welding Inspector (CWI)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Metallurgical and Quality Control Testing Supervisor

- Highlight your experience in supervising a team of technicians and managing a testing laboratory.

- Quantify your accomplishments with specific metrics, such as the percentage increase in production efficiency or reduction in testing time.

- Showcase your expertise in metallurgical testing techniques, such as metallography, non-destructive testing, and mechanical testing.

- Emphasize your ability to troubleshoot complex metallurgical issues and develop corrective actions.

Essential Experience Highlights for a Strong Metallurgical and Quality Control Testing Supervisor Resume

- Supervise a team of technicians in conducting metallurgical and quality control testing for steel, aluminum, and other metals

- Develop and implement new testing procedures to improve efficiency and accuracy

- Troubleshoot and resolve complex metallurgical issues to identify and mitigate risks

- Manage and maintain state-of-the-art testing equipment to ensure calibration and compliance

- Prepare and interpret comprehensive technical reports on testing results

- Provide technical support and guidance to engineers, operators, and customers

- Participate in failure analysis investigations to identify root causes and develop corrective actions

Frequently Asked Questions (FAQ’s) For Metallurgical and Quality Control Testing Supervisor

What are the key skills required for a Metallurgical and Quality Control Testing Supervisor?

The key skills required for a Metallurgical and Quality Control Testing Supervisor include a strong understanding of metallurgical principles, quality control procedures, and testing equipment. They should also have excellent communication, teamwork, and problem-solving skills.

What are the career prospects for a Metallurgical and Quality Control Testing Supervisor?

Metallurgical and Quality Control Testing Supervisors can advance to management positions, such as Quality Manager or Technical Director. They may also specialize in a particular area of metallurgy, such as failure analysis or corrosion control.

What are the challenges faced by a Metallurgical and Quality Control Testing Supervisor?

Metallurgical and Quality Control Testing Supervisors face a number of challenges, including the need to stay up-to-date on the latest testing techniques and industry standards. They must also be able to work independently and as part of a team to ensure that products meet quality and safety requirements.

What are the rewards of being a Metallurgical and Quality Control Testing Supervisor?

The rewards of being a Metallurgical and Quality Control Testing Supervisor include the opportunity to work in a challenging and rewarding field. They can also make a significant contribution to the safety and quality of products used by consumers.

What is the typical salary range for a Metallurgical and Quality Control Testing Supervisor?

The typical salary range for a Metallurgical and Quality Control Testing Supervisor varies depending on experience, location, and company size. According to Salary.com, the average salary for a Metallurgical and Quality Control Testing Supervisor in the United States is $75,000 per year.

What are the educational requirements for a Metallurgical and Quality Control Testing Supervisor?

Most Metallurgical and Quality Control Testing Supervisors have a bachelor’s degree in metallurgical engineering or materials science. Some employers may also require a master’s degree or professional certification.

What are the professional development opportunities for a Metallurgical and Quality Control Testing Supervisor?

Metallurgical and Quality Control Testing Supervisors can pursue professional development opportunities through continuing education courses, conferences, and workshops. They can also join professional organizations, such as the American Society for Metals (ASM) or the American Society for Quality (ASQ).