Are you a seasoned Methods Engineer seeking a new career path? Discover our professionally built Methods Engineer Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

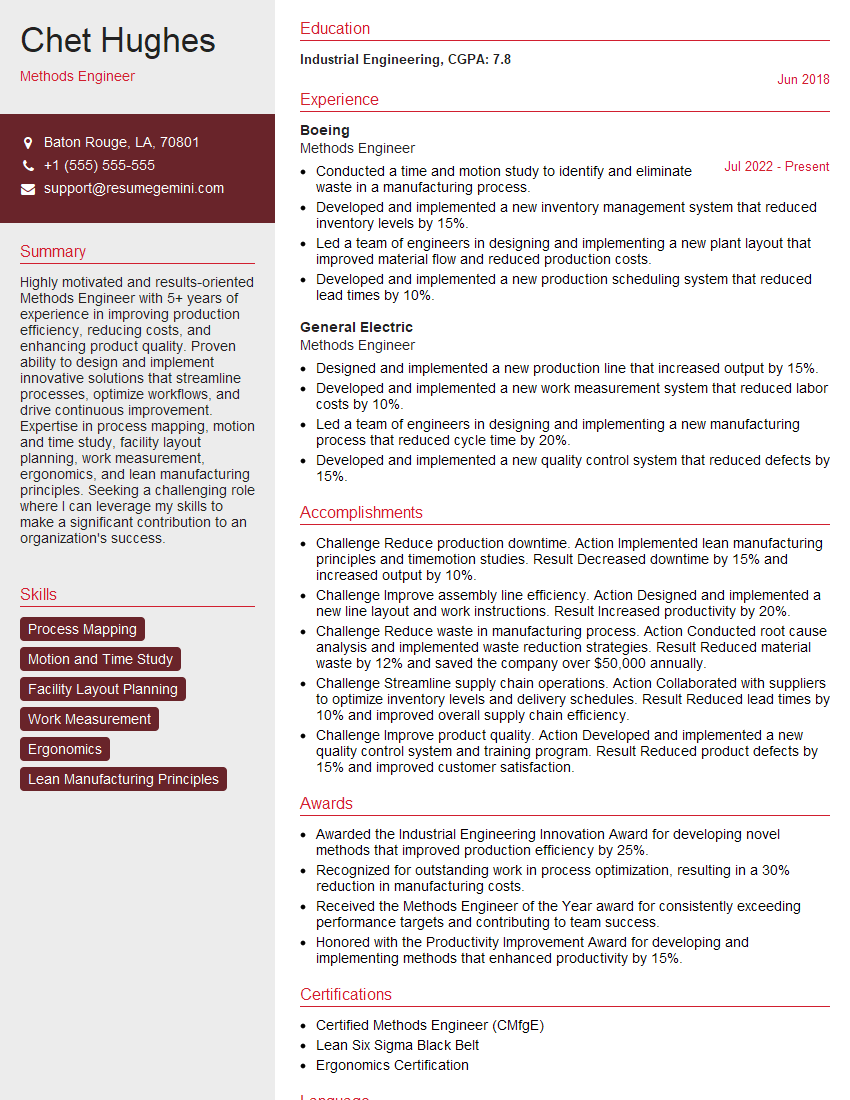

Chet Hughes

Methods Engineer

Summary

Highly motivated and results-oriented Methods Engineer with 5+ years of experience in improving production efficiency, reducing costs, and enhancing product quality. Proven ability to design and implement innovative solutions that streamline processes, optimize workflows, and drive continuous improvement. Expertise in process mapping, motion and time study, facility layout planning, work measurement, ergonomics, and lean manufacturing principles. Seeking a challenging role where I can leverage my skills to make a significant contribution to an organization’s success.

Education

Industrial Engineering

June 2018

Skills

- Process Mapping

- Motion and Time Study

- Facility Layout Planning

- Work Measurement

- Ergonomics

- Lean Manufacturing Principles

Work Experience

Methods Engineer

- Conducted a time and motion study to identify and eliminate waste in a manufacturing process.

- Developed and implemented a new inventory management system that reduced inventory levels by 15%.

- Led a team of engineers in designing and implementing a new plant layout that improved material flow and reduced production costs.

- Developed and implemented a new production scheduling system that reduced lead times by 10%.

Methods Engineer

- Designed and implemented a new production line that increased output by 15%.

- Developed and implemented a new work measurement system that reduced labor costs by 10%.

- Led a team of engineers in designing and implementing a new manufacturing process that reduced cycle time by 20%.

- Developed and implemented a new quality control system that reduced defects by 15%.

Accomplishments

- Challenge Reduce production downtime. Action Implemented lean manufacturing principles and timemotion studies. Result Decreased downtime by 15% and increased output by 10%.

- Challenge Improve assembly line efficiency. Action Designed and implemented a new line layout and work instructions. Result Increased productivity by 20%.

- Challenge Reduce waste in manufacturing process. Action Conducted root cause analysis and implemented waste reduction strategies. Result Reduced material waste by 12% and saved the company over $50,000 annually.

- Challenge Streamline supply chain operations. Action Collaborated with suppliers to optimize inventory levels and delivery schedules. Result Reduced lead times by 10% and improved overall supply chain efficiency.

- Challenge Improve product quality. Action Developed and implemented a new quality control system and training program. Result Reduced product defects by 15% and improved customer satisfaction.

Awards

- Awarded the Industrial Engineering Innovation Award for developing novel methods that improved production efficiency by 25%.

- Recognized for outstanding work in process optimization, resulting in a 30% reduction in manufacturing costs.

- Received the Methods Engineer of the Year award for consistently exceeding performance targets and contributing to team success.

- Honored with the Productivity Improvement Award for developing and implementing methods that enhanced productivity by 15%.

Certificates

- Certified Methods Engineer (CMfgE)

- Lean Six Sigma Black Belt

- Ergonomics Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Methods Engineer

- Quantify your accomplishments whenever possible using specific metrics and data to demonstrate the impact of your work.

- Highlight your experience in implementing lean manufacturing principles and continuous improvement methodologies.

- Emphasize your ability to work effectively with cross-functional teams and manage multiple projects simultaneously.

- Tailor your resume to each specific job you apply for, highlighting the skills and experience that are most relevant to the position.

Essential Experience Highlights for a Strong Methods Engineer Resume

- Designed and implemented process improvements that resulted in increased production output, reduced labor costs, shorter cycle times, and improved product quality.

- Developed and implemented work measurement systems to optimize labor utilization and reduce production costs.

- Led teams of engineers in designing and implementing new manufacturing processes and plant layouts to improve efficiency and reduce waste.

- Conducted time and motion studies to identify and eliminate inefficiencies in manufacturing processes.

- Implemented inventory management systems to reduce inventory levels and improve cash flow.

- Led the development and implementation of ergonomic solutions to improve workplace safety and employee comfort.

- Collaborated with cross-functional teams to identify and implement process improvements that aligned with the company’s overall strategic objectives.

Frequently Asked Questions (FAQ’s) For Methods Engineer

What is the role of a Methods Engineer?

A Methods Engineer is responsible for designing and implementing process improvements that streamline operations, reduce costs, and improve product quality. They analyze existing processes, identify inefficiencies, and develop and implement solutions to optimize workflows and maximize efficiency.

What skills are required to be a successful Methods Engineer?

Successful Methods Engineers typically possess a strong understanding of industrial engineering principles, process mapping, motion and time study, facility layout planning, work measurement, ergonomics, and lean manufacturing principles. They also have excellent analytical, problem-solving, and communication skills.

What industries employ Methods Engineers?

Methods Engineers are employed in a wide range of industries, including manufacturing, healthcare, logistics, and retail. Any industry that seeks to improve efficiency, reduce costs, and enhance product quality can benefit from the expertise of a Methods Engineer.

What is the career path for a Methods Engineer?

Methods Engineers can advance their careers by taking on leadership roles, such as Production Manager, Operations Manager, or Plant Manager. They can also specialize in a particular area, such as lean manufacturing or ergonomics, and become experts in their field.

What are the job prospects for Methods Engineers?

The job outlook for Methods Engineers is expected to be positive in the coming years, as organizations continue to seek ways to improve efficiency and reduce costs. The demand for skilled Methods Engineers is particularly high in industries that are undergoing rapid growth or technological change.

How can I become a Methods Engineer?

To become a Methods Engineer, you typically need a bachelor’s degree in industrial engineering or a related field. Some employers may also require a master’s degree or professional certification. Additionally, hands-on experience in manufacturing or process improvement is often beneficial.

What are the benefits of becoming a Methods Engineer?

Methods Engineers play a vital role in improving the efficiency and productivity of organizations. They have the opportunity to make a real difference in the success of their companies and the satisfaction of their customers.

What are the challenges of being a Methods Engineer?

Methods Engineers often face challenges related to implementing change in organizations. They need to be able to effectively communicate their ideas, gain buy-in from stakeholders, and overcome resistance to change.