Are you a seasoned Mill Oiler seeking a new career path? Discover our professionally built Mill Oiler Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

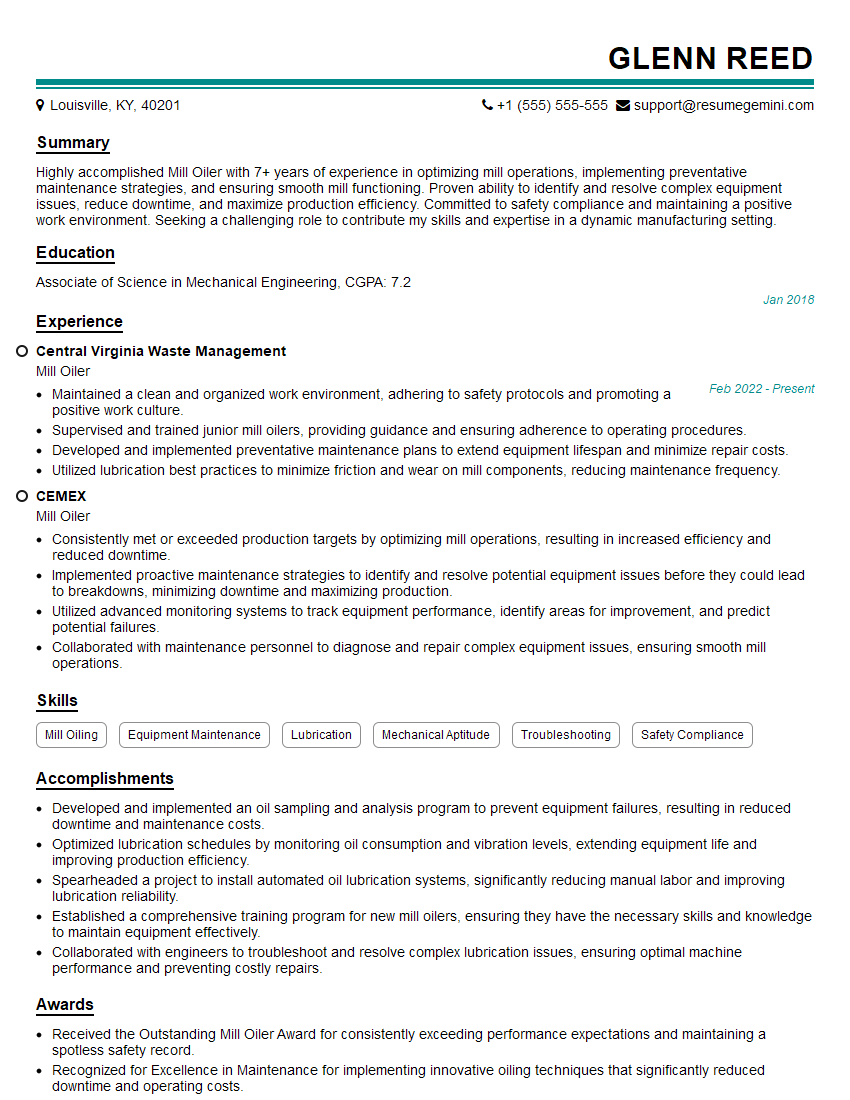

Glenn Reed

Mill Oiler

Summary

Highly accomplished Mill Oiler with 7+ years of experience in optimizing mill operations, implementing preventative maintenance strategies, and ensuring smooth mill functioning. Proven ability to identify and resolve complex equipment issues, reduce downtime, and maximize production efficiency. Committed to safety compliance and maintaining a positive work environment. Seeking a challenging role to contribute my skills and expertise in a dynamic manufacturing setting.

Education

Associate of Science in Mechanical Engineering

January 2018

Skills

- Mill Oiling

- Equipment Maintenance

- Lubrication

- Mechanical Aptitude

- Troubleshooting

- Safety Compliance

Work Experience

Mill Oiler

- Maintained a clean and organized work environment, adhering to safety protocols and promoting a positive work culture.

- Supervised and trained junior mill oilers, providing guidance and ensuring adherence to operating procedures.

- Developed and implemented preventative maintenance plans to extend equipment lifespan and minimize repair costs.

- Utilized lubrication best practices to minimize friction and wear on mill components, reducing maintenance frequency.

Mill Oiler

- Consistently met or exceeded production targets by optimizing mill operations, resulting in increased efficiency and reduced downtime.

- Implemented proactive maintenance strategies to identify and resolve potential equipment issues before they could lead to breakdowns, minimizing downtime and maximizing production.

- Utilized advanced monitoring systems to track equipment performance, identify areas for improvement, and predict potential failures.

- Collaborated with maintenance personnel to diagnose and repair complex equipment issues, ensuring smooth mill operations.

Accomplishments

- Developed and implemented an oil sampling and analysis program to prevent equipment failures, resulting in reduced downtime and maintenance costs.

- Optimized lubrication schedules by monitoring oil consumption and vibration levels, extending equipment life and improving production efficiency.

- Spearheaded a project to install automated oil lubrication systems, significantly reducing manual labor and improving lubrication reliability.

- Established a comprehensive training program for new mill oilers, ensuring they have the necessary skills and knowledge to maintain equipment effectively.

- Collaborated with engineers to troubleshoot and resolve complex lubrication issues, ensuring optimal machine performance and preventing costly repairs.

Awards

- Received the Outstanding Mill Oiler Award for consistently exceeding performance expectations and maintaining a spotless safety record.

- Recognized for Excellence in Maintenance for implementing innovative oiling techniques that significantly reduced downtime and operating costs.

- Awarded the Safety Superstar Award for adhering to strict safety protocols and implementing enhancements that improved workplace safety.

Certificates

- Certified Lubrication Technician

- Certified Maintenance and Reliability Technician

- Certified Millwright

- Certified Oil Analysis Technician

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Mill Oiler

- Highlight your experience in mill oiling, specifically mentioning your contributions to optimizing mill operations and reducing downtime.

- Emphasize your proactive maintenance skills, including your ability to identify and resolve potential equipment issues before they become major problems.

- Showcase your troubleshooting abilities, providing examples of complex equipment issues you have diagnosed and repaired.

- Demonstrate your commitment to safety and your ability to maintain a clean and organized work environment.

Essential Experience Highlights for a Strong Mill Oiler Resume

- Optimized mill operations to consistently meet or exceed production targets, resulting in increased efficiency and reduced downtime.

- Implemented proactive maintenance strategies to identify and resolve potential equipment issues before they could lead to breakdowns, minimizing downtime and maximizing production.

- Utilized advanced monitoring systems to track equipment performance, identify areas for improvement, and predict potential failures.

- Collaborated with maintenance personnel to diagnose and repair complex equipment issues, ensuring smooth mill operations.

- Maintained a clean and organized work environment, adhering to safety protocols and promoting a positive work culture.

- Developed and implemented preventative maintenance plans to extend equipment lifespan and minimize repair costs.

Frequently Asked Questions (FAQ’s) For Mill Oiler

What are the primary responsibilities of a Mill Oiler?

Mill Oilers are responsible for lubricating, maintaining, and repairing mill machinery to ensure smooth and efficient operations. They monitor equipment performance, identify potential issues, and take proactive measures to prevent breakdowns. Mill Oilers also maintain a clean and safe work environment, adhering to established safety protocols.

What qualifications are required to become a Mill Oiler?

Typically, a high school diploma or equivalent is sufficient to qualify for an entry-level Mill Oiler position. However, some employers may prefer candidates with an Associate of Science degree in Mechanical Engineering or a related field. Prior experience in a manufacturing or maintenance environment is also advantageous.

What is the work environment of a Mill Oiler like?

Mill Oilers typically work in industrial settings, such as factories or manufacturing plants. The work environment can be noisy and oily, and Mill Oilers may be exposed to hazardous chemicals and machinery. They must be able to work independently and as part of a team, and they must be able to follow instructions and work under pressure.

What are the career prospects for Mill Oilers?

Mill Oilers can advance their careers by gaining experience and developing their skills. They may be promoted to positions such as Maintenance Technician, Supervisor, or Manager. With additional education and training, Mill Oilers can also pursue careers in engineering or other technical fields.

What is the salary range for Mill Oilers?

The salary range for Mill Oilers varies depending on their experience, skills, and location. According to Salary.com, the median annual salary for Mill Oilers in the United States is $55,000. However, salaries can range from $40,000 to $75,000 or more.