Are you a seasoned Mine Equipment Design Engineer seeking a new career path? Discover our professionally built Mine Equipment Design Engineer Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

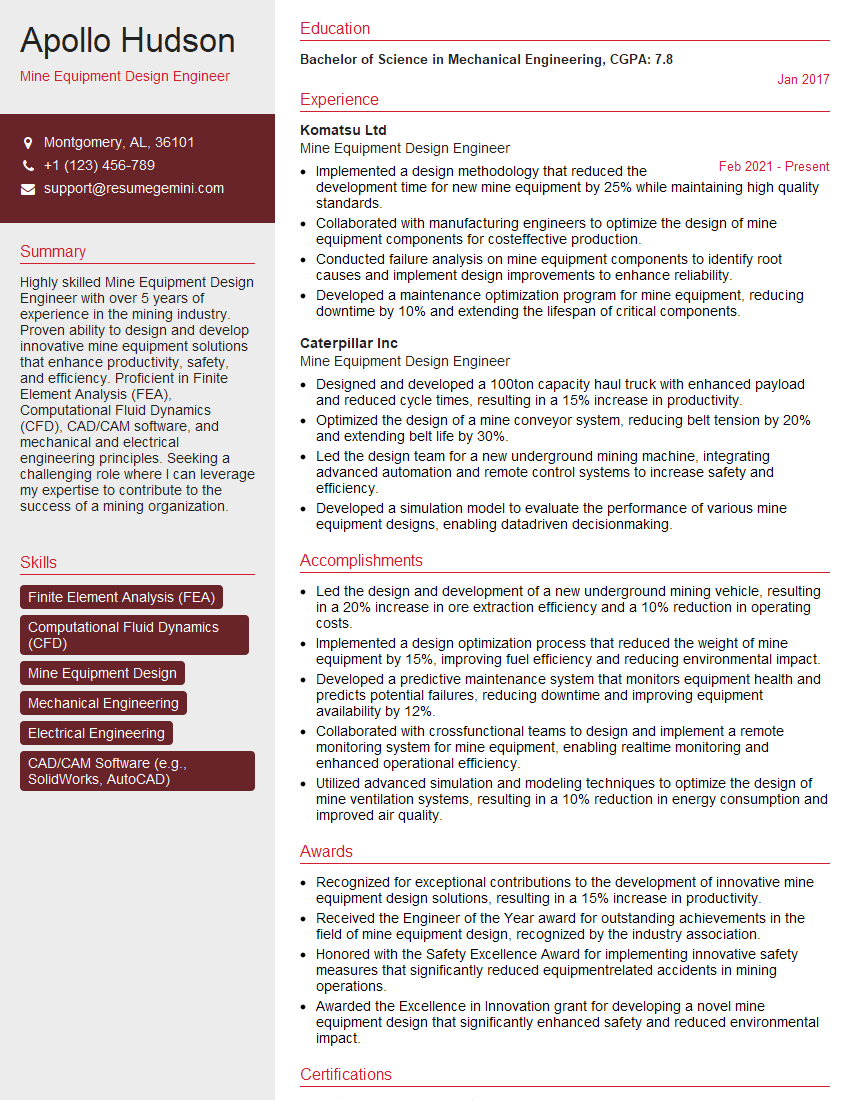

Apollo Hudson

Mine Equipment Design Engineer

Summary

Highly skilled Mine Equipment Design Engineer with over 5 years of experience in the mining industry. Proven ability to design and develop innovative mine equipment solutions that enhance productivity, safety, and efficiency. Proficient in Finite Element Analysis (FEA), Computational Fluid Dynamics (CFD), CAD/CAM software, and mechanical and electrical engineering principles. Seeking a challenging role where I can leverage my expertise to contribute to the success of a mining organization.

Education

Bachelor of Science in Mechanical Engineering

January 2017

Skills

- Finite Element Analysis (FEA)

- Computational Fluid Dynamics (CFD)

- Mine Equipment Design

- Mechanical Engineering

- Electrical Engineering

- CAD/CAM Software (e.g., SolidWorks, AutoCAD)

Work Experience

Mine Equipment Design Engineer

- Implemented a design methodology that reduced the development time for new mine equipment by 25% while maintaining high quality standards.

- Collaborated with manufacturing engineers to optimize the design of mine equipment components for costeffective production.

- Conducted failure analysis on mine equipment components to identify root causes and implement design improvements to enhance reliability.

- Developed a maintenance optimization program for mine equipment, reducing downtime by 10% and extending the lifespan of critical components.

Mine Equipment Design Engineer

- Designed and developed a 100ton capacity haul truck with enhanced payload and reduced cycle times, resulting in a 15% increase in productivity.

- Optimized the design of a mine conveyor system, reducing belt tension by 20% and extending belt life by 30%.

- Led the design team for a new underground mining machine, integrating advanced automation and remote control systems to increase safety and efficiency.

- Developed a simulation model to evaluate the performance of various mine equipment designs, enabling datadriven decisionmaking.

Accomplishments

- Led the design and development of a new underground mining vehicle, resulting in a 20% increase in ore extraction efficiency and a 10% reduction in operating costs.

- Implemented a design optimization process that reduced the weight of mine equipment by 15%, improving fuel efficiency and reducing environmental impact.

- Developed a predictive maintenance system that monitors equipment health and predicts potential failures, reducing downtime and improving equipment availability by 12%.

- Collaborated with crossfunctional teams to design and implement a remote monitoring system for mine equipment, enabling realtime monitoring and enhanced operational efficiency.

- Utilized advanced simulation and modeling techniques to optimize the design of mine ventilation systems, resulting in a 10% reduction in energy consumption and improved air quality.

Awards

- Recognized for exceptional contributions to the development of innovative mine equipment design solutions, resulting in a 15% increase in productivity.

- Received the Engineer of the Year award for outstanding achievements in the field of mine equipment design, recognized by the industry association.

- Honored with the Safety Excellence Award for implementing innovative safety measures that significantly reduced equipmentrelated accidents in mining operations.

- Awarded the Excellence in Innovation grant for developing a novel mine equipment design that significantly enhanced safety and reduced environmental impact.

Certificates

- Certified Mine Equipment Design Engineer (CMEDE)

- Certified Professional Engineer (PE)

- MSHA Part 48 Training

- Mine Safety and Health Administration (MSHA) Training

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Mine Equipment Design Engineer

- Highlight your experience in designing and developing mine equipment, including specific examples of your contributions and the impact of your work

- Showcase your proficiency in Finite Element Analysis (FEA) and Computational Fluid Dynamics (CFD), as these are essential skills for Mine Equipment Design Engineers

- Quantify your accomplishments whenever possible, using specific metrics to demonstrate the value you have added to previous organizations

- Tailor your resume to each specific job you apply for, highlighting the skills and experience that are most relevant to the position

- Proofread your resume carefully before submitting it to ensure there are no errors

Essential Experience Highlights for a Strong Mine Equipment Design Engineer Resume

- Design and develop new mine equipment, including haul trucks, conveyors, and underground mining machines

- Optimize existing mine equipment designs to improve performance, reduce costs, and extend lifespan

- Conduct failure analysis on mine equipment components to identify root causes and implement design improvements

- Develop and implement maintenance optimization programs to minimize downtime and extend the lifespan of critical components

- Collaborate with manufacturing engineers to optimize the design of mine equipment components for cost-effective production

- Utilize Finite Element Analysis (FEA) and Computational Fluid Dynamics (CFD) to evaluate the performance of mine equipment designs

- Stay abreast of the latest advancements in mine equipment design and technology

Frequently Asked Questions (FAQ’s) For Mine Equipment Design Engineer

What is the role of a Mine Equipment Design Engineer?

A Mine Equipment Design Engineer is responsible for designing and developing new mine equipment, as well as optimizing existing designs to improve performance, reduce costs, and extend lifespan. They also conduct failure analysis on mine equipment components to identify root causes and implement design improvements. Additionally, they develop and implement maintenance optimization programs to minimize downtime and extend the lifespan of critical components.

What skills are required to be a successful Mine Equipment Design Engineer?

The most important skills for a Mine Equipment Design Engineer are proficiency in Finite Element Analysis (FEA) and Computational Fluid Dynamics (CFD), as well as a strong understanding of mechanical and electrical engineering principles. They should also have experience in designing and developing mine equipment, as well as a strong understanding of the mining industry.

What are the career prospects for Mine Equipment Design Engineers?

Mine Equipment Design Engineers are in high demand due to the increasing need for safe and efficient mining equipment. The career prospects for Mine Equipment Design Engineers are excellent, with many opportunities for advancement to senior-level positions.

What is the salary range for Mine Equipment Design Engineers?

The salary range for Mine Equipment Design Engineers varies depending on experience and location. However, the average salary for Mine Equipment Design Engineers is around $100,000 per year.

What are the challenges faced by Mine Equipment Design Engineers?

Mine Equipment Design Engineers face a number of challenges, including the need to design equipment that is safe, efficient, and cost-effective. They also need to stay abreast of the latest advancements in mine equipment design and technology.

What is the work environment for Mine Equipment Design Engineers?

Mine Equipment Design Engineers typically work in an office setting. However, they may also need to visit mines to conduct site inspections or to troubleshoot problems with equipment.

What are the benefits of working as a Mine Equipment Design Engineer?

Mine Equipment Design Engineers enjoy a number of benefits, including a competitive salary, a challenging and rewarding career, and the opportunity to make a real difference in the mining industry.

What is the future of the Mine Equipment Design Engineering profession?

The future of the Mine Equipment Design Engineering profession is bright. The increasing demand for safe and efficient mining equipment is expected to drive growth in the profession. Additionally, the development of new technologies, such as autonomous mining equipment, is expected to create new opportunities for Mine Equipment Design Engineers.