Are you a seasoned Mold and Die Technician seeking a new career path? Discover our professionally built Mold and Die Technician Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

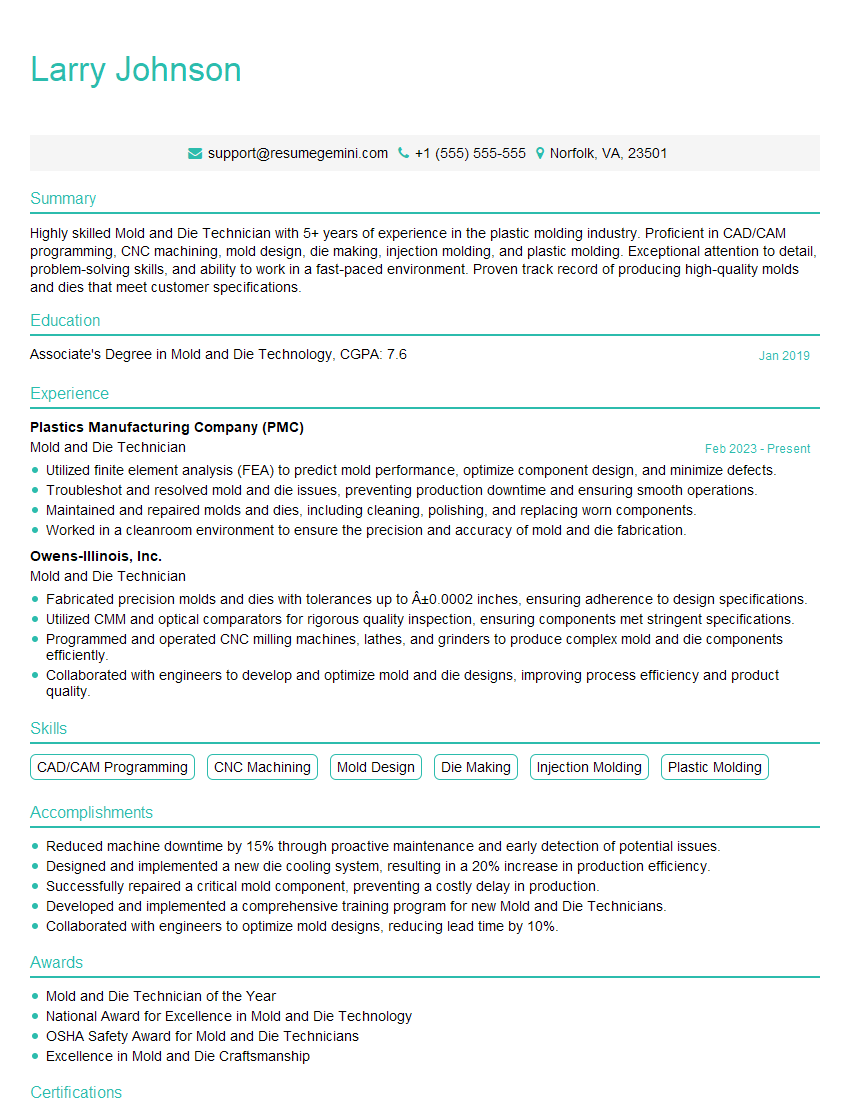

Larry Johnson

Mold and Die Technician

Summary

Highly skilled Mold and Die Technician with 5+ years of experience in the plastic molding industry. Proficient in CAD/CAM programming, CNC machining, mold design, die making, injection molding, and plastic molding. Exceptional attention to detail, problem-solving skills, and ability to work in a fast-paced environment. Proven track record of producing high-quality molds and dies that meet customer specifications.

Education

Associate’s Degree in Mold and Die Technology

January 2019

Skills

- CAD/CAM Programming

- CNC Machining

- Mold Design

- Die Making

- Injection Molding

- Plastic Molding

Work Experience

Mold and Die Technician

- Utilized finite element analysis (FEA) to predict mold performance, optimize component design, and minimize defects.

- Troubleshot and resolved mold and die issues, preventing production downtime and ensuring smooth operations.

- Maintained and repaired molds and dies, including cleaning, polishing, and replacing worn components.

- Worked in a cleanroom environment to ensure the precision and accuracy of mold and die fabrication.

Mold and Die Technician

- Fabricated precision molds and dies with tolerances up to ±0.0002 inches, ensuring adherence to design specifications.

- Utilized CMM and optical comparators for rigorous quality inspection, ensuring components met stringent specifications.

- Programmed and operated CNC milling machines, lathes, and grinders to produce complex mold and die components efficiently.

- Collaborated with engineers to develop and optimize mold and die designs, improving process efficiency and product quality.

Accomplishments

- Reduced machine downtime by 15% through proactive maintenance and early detection of potential issues.

- Designed and implemented a new die cooling system, resulting in a 20% increase in production efficiency.

- Successfully repaired a critical mold component, preventing a costly delay in production.

- Developed and implemented a comprehensive training program for new Mold and Die Technicians.

- Collaborated with engineers to optimize mold designs, reducing lead time by 10%.

Awards

- Mold and Die Technician of the Year

- National Award for Excellence in Mold and Die Technology

- OSHA Safety Award for Mold and Die Technicians

- Excellence in Mold and Die Craftsmanship

Certificates

- Certified Mold Maker (CMM)

- Certified Plastics Technician (CPT)

- Certified Manufacturing Engineer (CMfgE)

- ASQ Certified Quality Inspector (CQI)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Mold and Die Technician

- Highlight your technical skills, including proficiency in CAD/CAM, CNC machining, and mold and die making.

- Quantify your accomplishments and provide specific examples of how you have contributed to the success of previous projects.

- Demonstrate your problem-solving abilities and provide examples of how you have overcome challenges in the workplace.

- Tailor your resume to each specific job application, highlighting the skills and experience that are most relevant to the position.

Essential Experience Highlights for a Strong Mold and Die Technician Resume

- Designed and developed molds and dies using CAD/CAM software.

- Programmed and operated CNC machines to create molds and dies.

- Assembled and repaired molds and dies, ensuring proper fit and function.

- Tested and inspected molds and dies to verify accuracy and performance.

- Troubleshooted and resolved issues with molds and dies during production.

- Maintained a clean and organized work area, adhering to safety protocols.

- Collaborated with engineers and production team to ensure efficient mold and die production.

Frequently Asked Questions (FAQ’s) For Mold and Die Technician

What are the educational requirements to become a Mold and Die Technician?

Most Mold and Die Technicians have an associate’s degree in mold and die technology or a related field. Some may also have a certificate or diploma in mold and die making.

What are the key skills required for a Mold and Die Technician?

The key skills required for a Mold and Die Technician include CAD/CAM programming, CNC machining, mold design, die making, injection molding, and plastic molding.

What is the job outlook for Mold and Die Technicians?

The job outlook for Mold and Die Technicians is expected to be good over the next few years. The demand for skilled workers in this field is expected to remain strong due to the increasing use of plastics in various industries.

What is the average salary for a Mold and Die Technician?

The average salary for a Mold and Die Technician in the United States is around $59,000 per year.

What are the growth opportunities for Mold and Die Technicians?

Mold and Die Technicians can advance their careers by becoming supervisors, managers, or engineers. They may also specialize in a particular area of mold and die making, such as mold design or CNC programming.

What are the working conditions like for Mold and Die Technicians?

Mold and Die Technicians typically work in a shop environment. They may be exposed to noise, dust, and chemicals. They may also need to lift heavy objects and work in awkward positions.