Are you a seasoned Mold Tooling Technician seeking a new career path? Discover our professionally built Mold Tooling Technician Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

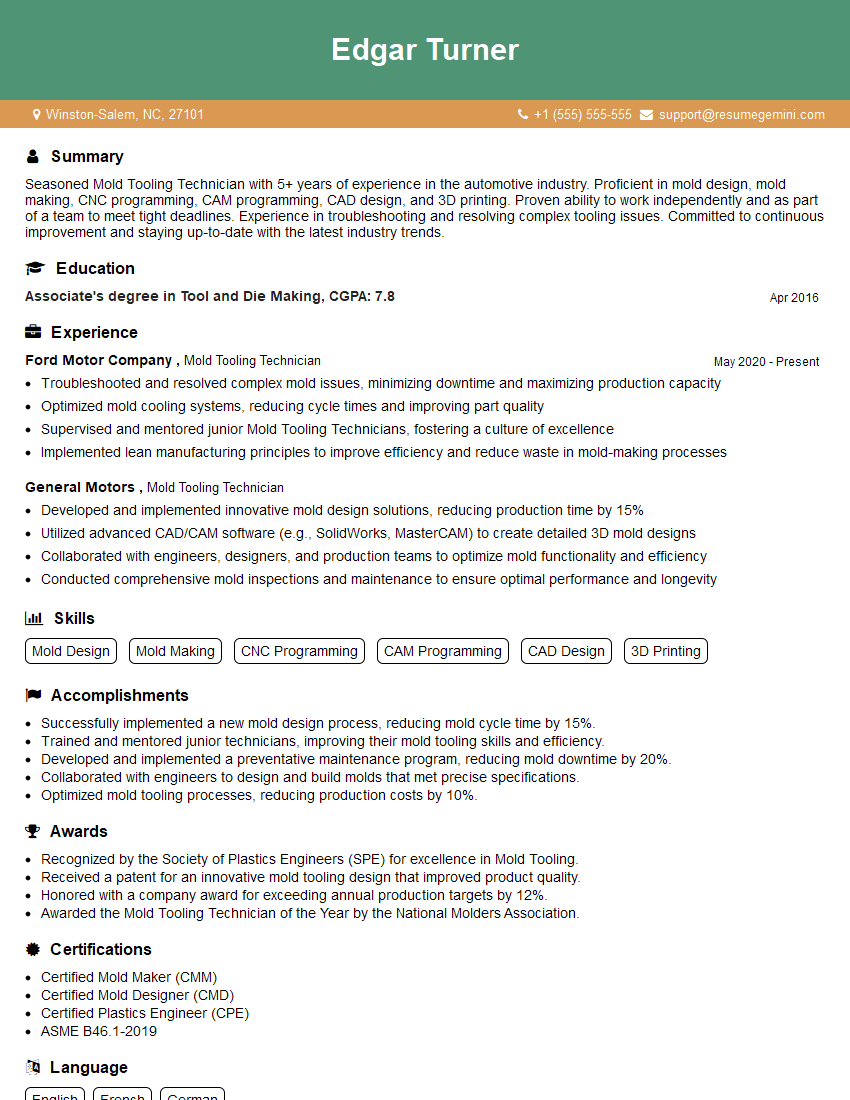

Edgar Turner

Mold Tooling Technician

Summary

Seasoned Mold Tooling Technician with 5+ years of experience in the automotive industry. Proficient in mold design, mold making, CNC programming, CAM programming, CAD design, and 3D printing. Proven ability to work independently and as part of a team to meet tight deadlines. Experience in troubleshooting and resolving complex tooling issues. Committed to continuous improvement and staying up-to-date with the latest industry trends.

Education

Associate’s degree in Tool and Die Making

April 2016

Skills

- Mold Design

- Mold Making

- CNC Programming

- CAM Programming

- CAD Design

- 3D Printing

Work Experience

Mold Tooling Technician

- Troubleshooted and resolved complex mold issues, minimizing downtime and maximizing production capacity

- Optimized mold cooling systems, reducing cycle times and improving part quality

- Supervised and mentored junior Mold Tooling Technicians, fostering a culture of excellence

- Implemented lean manufacturing principles to improve efficiency and reduce waste in mold-making processes

Mold Tooling Technician

- Developed and implemented innovative mold design solutions, reducing production time by 15%

- Utilized advanced CAD/CAM software (e.g., SolidWorks, MasterCAM) to create detailed 3D mold designs

- Collaborated with engineers, designers, and production teams to optimize mold functionality and efficiency

- Conducted comprehensive mold inspections and maintenance to ensure optimal performance and longevity

Accomplishments

- Successfully implemented a new mold design process, reducing mold cycle time by 15%.

- Trained and mentored junior technicians, improving their mold tooling skills and efficiency.

- Developed and implemented a preventative maintenance program, reducing mold downtime by 20%.

- Collaborated with engineers to design and build molds that met precise specifications.

- Optimized mold tooling processes, reducing production costs by 10%.

Awards

- Recognized by the Society of Plastics Engineers (SPE) for excellence in Mold Tooling.

- Received a patent for an innovative mold tooling design that improved product quality.

- Honored with a company award for exceeding annual production targets by 12%.

- Awarded the Mold Tooling Technician of the Year by the National Molders Association.

Certificates

- Certified Mold Maker (CMM)

- Certified Mold Designer (CMD)

- Certified Plastics Engineer (CPE)

- ASME B46.1-2019

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Mold Tooling Technician

- Highlight your experience with mold design and making.

- Showcase your skills in CNC programming and CAM programming.

- Emphasize your ability to troubleshoot and resolve tooling issues.

- Demonstrate your commitment to continuous improvement and learning.

Essential Experience Highlights for a Strong Mold Tooling Technician Resume

- Design and develop molds for automotive parts using CAD software.

- Program and operate CNC machines to create mold components.

- Assemble and inspect molds to ensure they meet specifications.

- Troubleshoot and resolve mold tooling issues.

- Maintain and repair mold tooling equipment.

- Work with engineers and other team members to develop and implement new tooling solutions.

- Stay up-to-date with the latest mold tooling technologies and trends.

Frequently Asked Questions (FAQ’s) For Mold Tooling Technician

What are the key skills required for a Mold Tooling Technician?

The key skills required for a Mold Tooling Technician include mold design, mold making, CNC programming, CAM programming, CAD design, and 3D printing.

What is the typical work environment for a Mold Tooling Technician?

Mold Tooling Technicians typically work in a manufacturing environment, where they use specialized equipment to create molds for automotive parts.

What is the career outlook for a Mold Tooling Technician?

The career outlook for Mold Tooling Technicians is expected to be good, as the demand for skilled workers in the manufacturing industry continues to grow.

What are the typical salary expectations for a Mold Tooling Technician?

The typical salary expectations for a Mold Tooling Technician vary depending on experience and location, but can range from $40,000 to $70,000 per year.

What are the common challenges faced by Mold Tooling Technicians?

Common challenges faced by Mold Tooling Technicians include working with tight deadlines, troubleshooting complex tooling issues, and staying up-to-date with the latest industry trends.

What are the key qualities of a successful Mold Tooling Technician?

Key qualities of a successful Mold Tooling Technician include attention to detail, problem-solving skills, and a commitment to continuous improvement.

What are the steps to becoming a Mold Tooling Technician?

To become a Mold Tooling Technician, you typically need an associate’s degree in Tool and Die Making, as well as experience with mold design, mold making, and CNC programming.

What are the certifications available for Mold Tooling Technicians?

There are several certifications available for Mold Tooling Technicians, including the Certified Mold Maker (CMM) and the Certified Mold Designer (CMD) certifications.