Are you a seasoned Molder Operator seeking a new career path? Discover our professionally built Molder Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

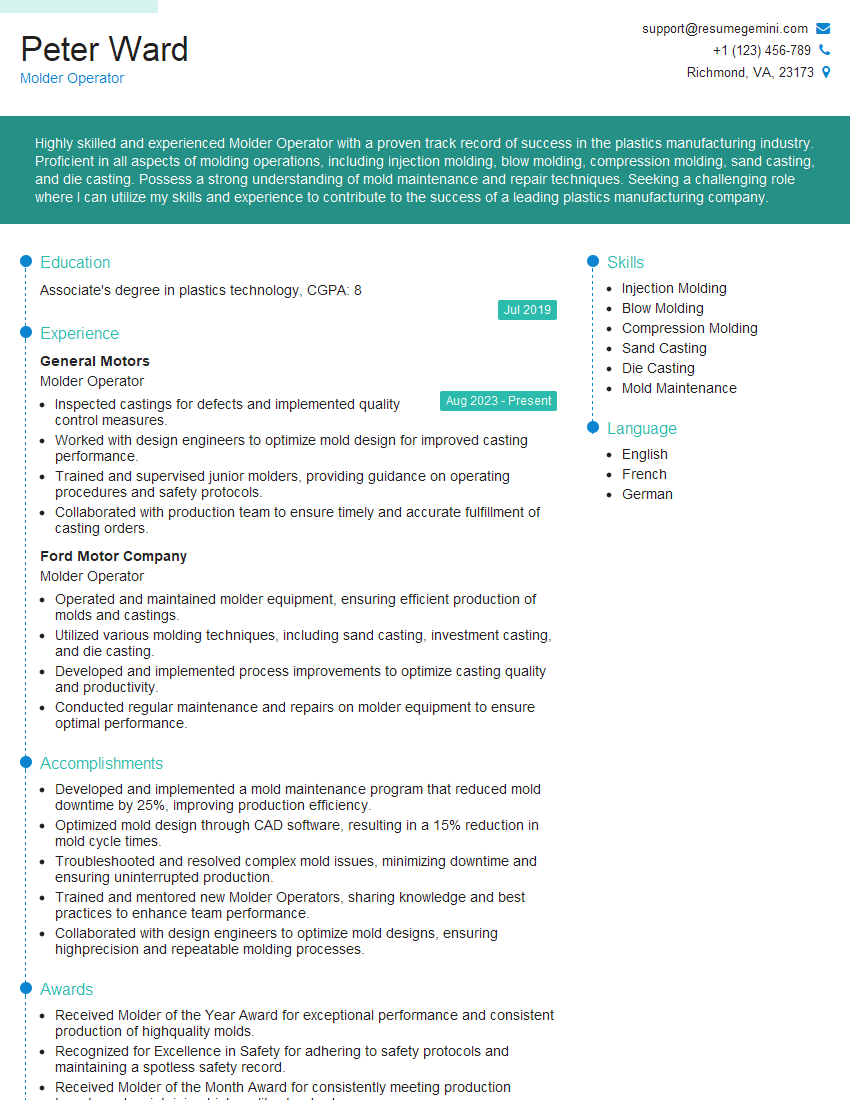

Peter Ward

Molder Operator

Summary

Highly skilled and experienced Molder Operator with a proven track record of success in the plastics manufacturing industry. Proficient in all aspects of molding operations, including injection molding, blow molding, compression molding, sand casting, and die casting. Possess a strong understanding of mold maintenance and repair techniques. Seeking a challenging role where I can utilize my skills and experience to contribute to the success of a leading plastics manufacturing company.

Education

Associate’s degree in plastics technology

July 2019

Skills

- Injection Molding

- Blow Molding

- Compression Molding

- Sand Casting

- Die Casting

- Mold Maintenance

Work Experience

Molder Operator

- Inspected castings for defects and implemented quality control measures.

- Worked with design engineers to optimize mold design for improved casting performance.

- Trained and supervised junior molders, providing guidance on operating procedures and safety protocols.

- Collaborated with production team to ensure timely and accurate fulfillment of casting orders.

Molder Operator

- Operated and maintained molder equipment, ensuring efficient production of molds and castings.

- Utilized various molding techniques, including sand casting, investment casting, and die casting.

- Developed and implemented process improvements to optimize casting quality and productivity.

- Conducted regular maintenance and repairs on molder equipment to ensure optimal performance.

Accomplishments

- Developed and implemented a mold maintenance program that reduced mold downtime by 25%, improving production efficiency.

- Optimized mold design through CAD software, resulting in a 15% reduction in mold cycle times.

- Troubleshooted and resolved complex mold issues, minimizing downtime and ensuring uninterrupted production.

- Trained and mentored new Molder Operators, sharing knowledge and best practices to enhance team performance.

- Collaborated with design engineers to optimize mold designs, ensuring highprecision and repeatable molding processes.

Awards

- Received Molder of the Year Award for exceptional performance and consistent production of highquality molds.

- Recognized for Excellence in Safety for adhering to safety protocols and maintaining a spotless safety record.

- Received Molder of the Month Award for consistently meeting production targets and maintaining highquality standards.

- Nominated for Employee of the Quarter Award for exceptional contributions to the Molder Operator team.

Certificates

- Certified Molding Technician (CMT)

- Certified Plastics Technician (CPT)

- Certified Molding Engineer (CME)

- Certified Quality Technician (CQT)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Molder Operator

- Highlight your experience and skills in different molding techniques, such as injection molding, blow molding, and compression molding.

- Showcase your knowledge of mold maintenance and repair, including troubleshooting and preventive maintenance tasks.

- Quantify your accomplishments whenever possible, using specific metrics to demonstrate the impact of your work.

- Proofread your resume carefully for any errors in grammar, spelling, or formatting.

Essential Experience Highlights for a Strong Molder Operator Resume

- Operate and maintain molding machines to produce plastic parts and components.

- Set up and adjust molding machines according to specifications.

- Monitor molding processes and make necessary adjustments to ensure quality and efficiency.

- Inspect finished products for defects and ensure they meet customer requirements.

- Perform routine maintenance and repairs on molding machines and related equipment.

- Troubleshoot and resolve molding problems to minimize downtime and maintain productivity.

- Follow safety protocols and maintain a clean and organized work environment.

Frequently Asked Questions (FAQ’s) For Molder Operator

What are the different types of molding?

The most common types of molding include injection molding, blow molding, compression molding, sand casting, and die casting.

What are the key skills required for a Molder Operator?

Key skills for a Molder Operator include proficiency in operating and maintaining molding machines, setting up and adjusting molding machines, monitoring molding processes, inspecting finished products, performing routine maintenance and repairs, and troubleshooting and resolving molding problems.

What are the educational requirements for becoming a Molder Operator?

Most Molder Operators have an associate’s degree in plastics technology or a related field.

What is the career outlook for Molder Operators?

The job outlook for Molder Operators is expected to be good over the next few years due to the increasing demand for plastic products.

What are the salary expectations for Molder Operators?

The salary expectations for Molder Operators vary depending on experience, location, and company size, but the average salary is around $40,000 per year.

What are the benefits of working as a Molder Operator?

Benefits of working as a Molder Operator include job security, opportunities for advancement, and the chance to work with cutting-edge technology.