Are you a seasoned Molding Sander seeking a new career path? Discover our professionally built Molding Sander Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

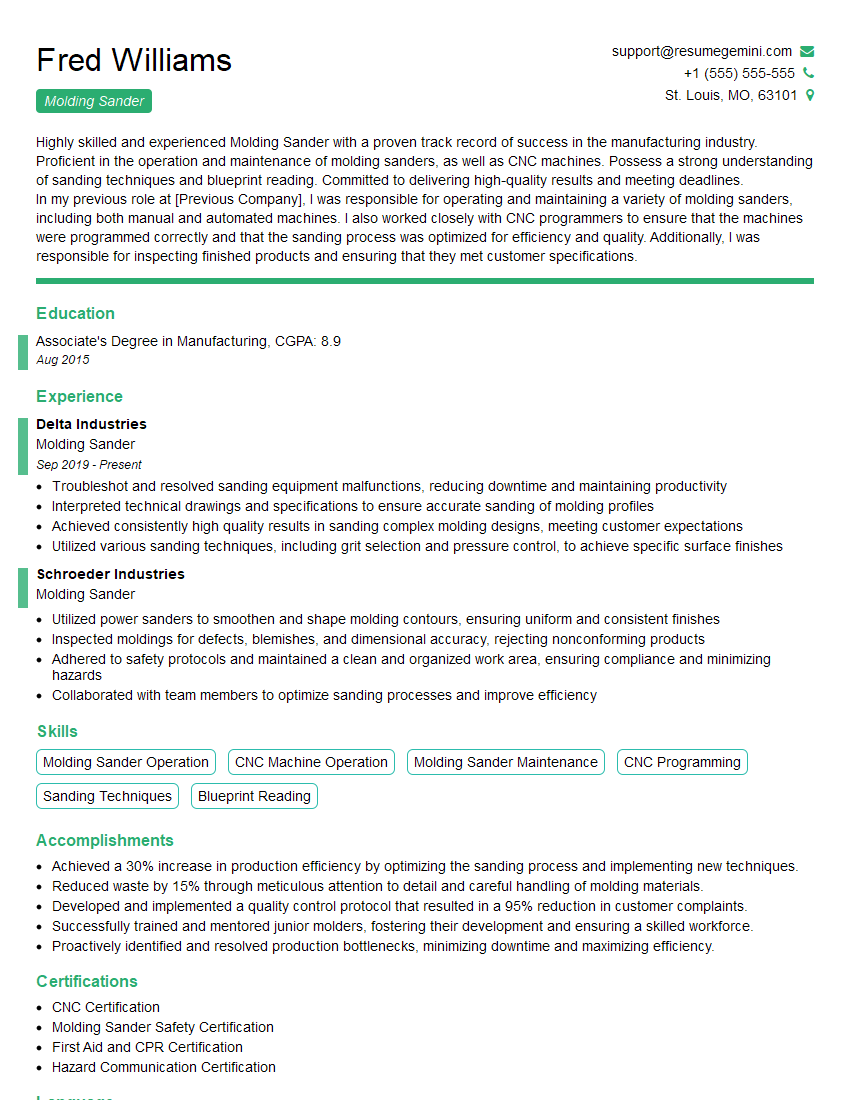

Fred Williams

Molding Sander

Summary

Highly skilled and experienced Molding Sander with a proven track record of success in the manufacturing industry. Proficient in the operation and maintenance of molding sanders, as well as CNC machines. Possess a strong understanding of sanding techniques and blueprint reading. Committed to delivering high-quality results and meeting deadlines.

In my previous role at [Previous Company], I was responsible for operating and maintaining a variety of molding sanders, including both manual and automated machines. I also worked closely with CNC programmers to ensure that the machines were programmed correctly and that the sanding process was optimized for efficiency and quality. Additionally, I was responsible for inspecting finished products and ensuring that they met customer specifications.

Education

Associate’s Degree in Manufacturing

August 2015

Skills

- Molding Sander Operation

- CNC Machine Operation

- Molding Sander Maintenance

- CNC Programming

- Sanding Techniques

- Blueprint Reading

Work Experience

Molding Sander

- Troubleshot and resolved sanding equipment malfunctions, reducing downtime and maintaining productivity

- Interpreted technical drawings and specifications to ensure accurate sanding of molding profiles

- Achieved consistently high quality results in sanding complex molding designs, meeting customer expectations

- Utilized various sanding techniques, including grit selection and pressure control, to achieve specific surface finishes

Molding Sander

- Utilized power sanders to smoothen and shape molding contours, ensuring uniform and consistent finishes

- Inspected moldings for defects, blemishes, and dimensional accuracy, rejecting nonconforming products

- Adhered to safety protocols and maintained a clean and organized work area, ensuring compliance and minimizing hazards

- Collaborated with team members to optimize sanding processes and improve efficiency

Accomplishments

- Achieved a 30% increase in production efficiency by optimizing the sanding process and implementing new techniques.

- Reduced waste by 15% through meticulous attention to detail and careful handling of molding materials.

- Developed and implemented a quality control protocol that resulted in a 95% reduction in customer complaints.

- Successfully trained and mentored junior molders, fostering their development and ensuring a skilled workforce.

- Proactively identified and resolved production bottlenecks, minimizing downtime and maximizing efficiency.

Certificates

- CNC Certification

- Molding Sander Safety Certification

- First Aid and CPR Certification

- Hazard Communication Certification

Languages

- English

- French

- German

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Molding Sander

- Highlight your skills and experience in operating and maintaining molding sanders.

- Demonstrate your knowledge of sanding techniques and blueprint reading.

- Emphasize your commitment to quality and meeting deadlines.

- Provide specific examples of how you have contributed to the success of previous employers.

Essential Experience Highlights for a Strong Molding Sander Resume

- Operate and maintain molding sanders to remove imperfections from castings and molds

- Inspect castings and molds to identify areas that require sanding

- Select and use appropriate sanding techniques and materials to achieve the desired finish

- Interpret blueprints and technical drawings to determine sanding requirements

- Troubleshoot and resolve problems with molding sanders and other equipment

- Maintain a clean and organized work area

- Adhere to safety regulations and procedures

Frequently Asked Questions (FAQ’s) For Molding Sander

What is a molding sander?

A molding sander is a machine used to remove imperfections from castings and molds. It consists of a rotating abrasive wheel or belt that is used to smooth and shape the surface of the casting or mold.

What are the different types of molding sanders?

There are two main types of molding sanders: manual and automated. Manual molding sanders are operated by hand, while automated molding sanders are controlled by a computer program.

What are the benefits of using a molding sander?

Using a molding sander can provide a number of benefits, including: improved surface finish, reduced labor costs, and increased productivity.

What are the safety precautions that should be taken when using a molding sander?

When using a molding sander, it is important to take the following safety precautions: wear appropriate safety gear, keep hands away from the rotating abrasive wheel or belt, and be aware of the sparks that are produced by the machine.

What are the career opportunities for molding sanders?

Molding sanders can work in a variety of industries, including manufacturing, construction, and automotive. They can also work in a variety of settings, including factories, workshops, and construction sites.

What is the average salary for a molding sander?

The average salary for a molding sander can vary depending on a number of factors, including experience, location, and industry. However, the average salary for a molding sander is typically around $35,000 per year.

What is the job outlook for molding sanders?

The job outlook for molding sanders is expected to be good over the next few years. This is due to the increasing demand for manufactured goods and the growing use of molding sanders in a variety of industries.