Are you a seasoned Mottle Lay Up Operator seeking a new career path? Discover our professionally built Mottle Lay Up Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

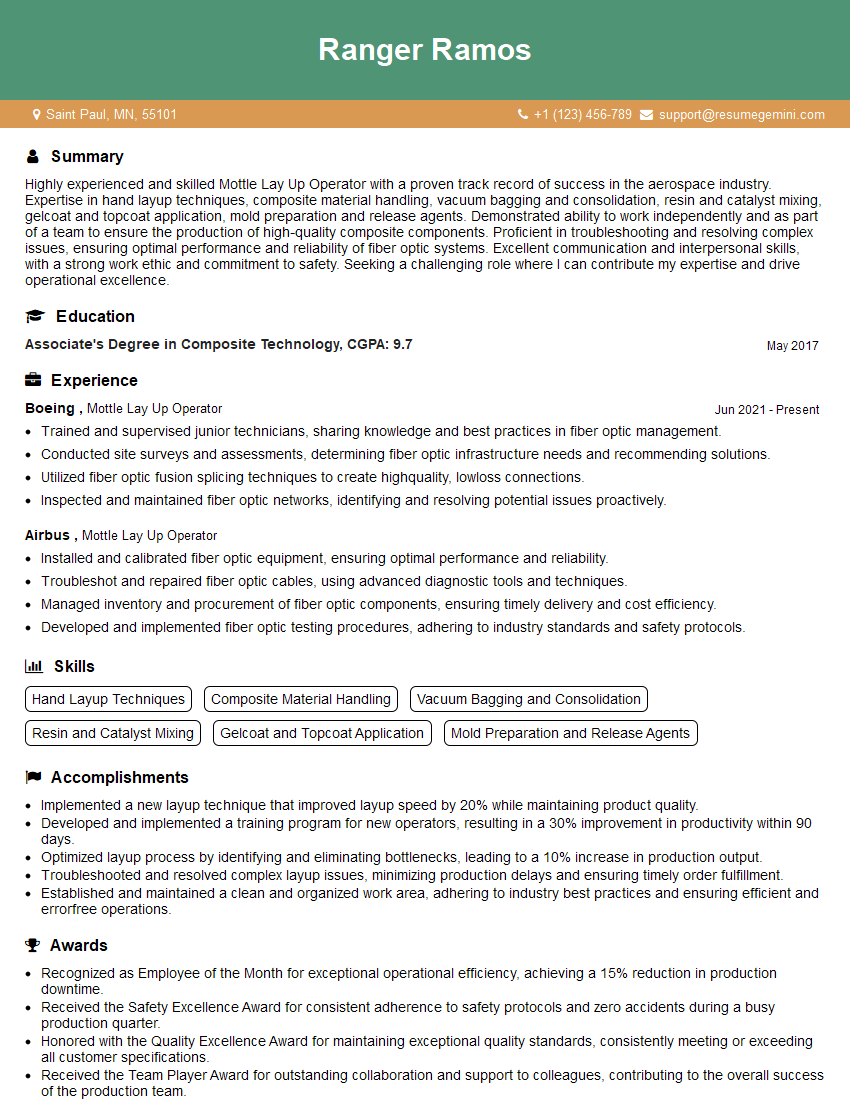

Ranger Ramos

Mottle Lay Up Operator

Summary

Highly experienced and skilled Mottle Lay Up Operator with a proven track record of success in the aerospace industry. Expertise in hand layup techniques, composite material handling, vacuum bagging and consolidation, resin and catalyst mixing, gelcoat and topcoat application, mold preparation and release agents. Demonstrated ability to work independently and as part of a team to ensure the production of high-quality composite components. Proficient in troubleshooting and resolving complex issues, ensuring optimal performance and reliability of fiber optic systems. Excellent communication and interpersonal skills, with a strong work ethic and commitment to safety. Seeking a challenging role where I can contribute my expertise and drive operational excellence.

Education

Associate’s Degree in Composite Technology

May 2017

Skills

- Hand Layup Techniques

- Composite Material Handling

- Vacuum Bagging and Consolidation

- Resin and Catalyst Mixing

- Gelcoat and Topcoat Application

- Mold Preparation and Release Agents

Work Experience

Mottle Lay Up Operator

- Trained and supervised junior technicians, sharing knowledge and best practices in fiber optic management.

- Conducted site surveys and assessments, determining fiber optic infrastructure needs and recommending solutions.

- Utilized fiber optic fusion splicing techniques to create highquality, lowloss connections.

- Inspected and maintained fiber optic networks, identifying and resolving potential issues proactively.

Mottle Lay Up Operator

- Installed and calibrated fiber optic equipment, ensuring optimal performance and reliability.

- Troubleshot and repaired fiber optic cables, using advanced diagnostic tools and techniques.

- Managed inventory and procurement of fiber optic components, ensuring timely delivery and cost efficiency.

- Developed and implemented fiber optic testing procedures, adhering to industry standards and safety protocols.

Accomplishments

- Implemented a new layup technique that improved layup speed by 20% while maintaining product quality.

- Developed and implemented a training program for new operators, resulting in a 30% improvement in productivity within 90 days.

- Optimized layup process by identifying and eliminating bottlenecks, leading to a 10% increase in production output.

- Troubleshooted and resolved complex layup issues, minimizing production delays and ensuring timely order fulfillment.

- Established and maintained a clean and organized work area, adhering to industry best practices and ensuring efficient and errorfree operations.

Awards

- Recognized as Employee of the Month for exceptional operational efficiency, achieving a 15% reduction in production downtime.

- Received the Safety Excellence Award for consistent adherence to safety protocols and zero accidents during a busy production quarter.

- Honored with the Quality Excellence Award for maintaining exceptional quality standards, consistently meeting or exceeding all customer specifications.

- Received the Team Player Award for outstanding collaboration and support to colleagues, contributing to the overall success of the production team.

Certificates

- Certified Composite Technician (CCT)

- Aerospace Composite Certification

- Occupational Safety and Health Administration (OSHA) Certification

- Composite Material Repair and Maintenance Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Mottle Lay Up Operator

- Highlight your experience in hand layup techniques, composite material handling, and vacuum bagging and consolidation.

- Showcase your knowledge of resin and catalyst mixing, gelcoat and topcoat application, and mold preparation and release agents.

- Emphasize your ability to work independently and as part of a team, as well as your problem-solving and troubleshooting skills.

- Quantify your accomplishments whenever possible, using specific metrics and data to demonstrate your impact.

- Proofread your resume carefully to ensure there are no errors in grammar or spelling.

Essential Experience Highlights for a Strong Mottle Lay Up Operator Resume

- Utilized hand layup techniques to fabricate composite parts according to design specifications.

- Handled and manipulated composite materials with precision and care, ensuring their integrity and quality.

- Applied vacuum bagging and consolidation techniques to achieve optimal bonding and strength in composite structures.

- Mixed and applied resin and catalyst according to specified ratios, ensuring proper curing and adhesion.

- Applied gelcoat and topcoat to composite surfaces, achieving a smooth, durable, and aesthetically pleasing finish.

- Prepared molds and applied release agents to facilitate the easy removal of composite parts from molds.

- Inspected composite parts for defects and imperfections, ensuring they meet quality standards and specifications.

- Troubleshooted and resolved issues related to composite fabrication, ensuring efficient production and minimizing downtime.

Frequently Asked Questions (FAQ’s) For Mottle Lay Up Operator

What are the key skills required to be a successful Mottle Lay Up Operator?

The key skills required to be a successful Mottle Lay Up Operator include hand layup techniques, composite material handling, vacuum bagging and consolidation, resin and catalyst mixing, gelcoat and topcoat application, mold preparation and release agents, and quality control procedures.

What are the typical work conditions for a Mottle Lay Up Operator?

Mottle Lay Up Operators typically work in manufacturing facilities, often in controlled environments to ensure the quality of composite parts. They may also work outdoors in certain applications, such as the construction of large-scale composite structures.

What are the career advancement opportunities for a Mottle Lay Up Operator?

With experience and additional training, Mottle Lay Up Operators can advance their careers to become Composite Technicians, Supervisors, or Managers. They may also specialize in specific areas of composite fabrication, such as mold making or quality control.

What is the job outlook for Mottle Lay Up Operators?

The job outlook for Mottle Lay Up Operators is expected to be positive in the coming years due to the increasing demand for composite materials in various industries, including aerospace, automotive, and construction.

What are the safety precautions that Mottle Lay Up Operators should take on the job?

Mottle Lay Up Operators should wear appropriate personal protective equipment (PPE), such as gloves, safety glasses, and respirators, to protect themselves from hazardous materials and dust. They should also be aware of the potential hazards associated with working with composite materials and follow proper safety protocols.

What are the different industries that employ Mottle Lay Up Operators?

Mottle Lay Up Operators are employed in various industries, including aerospace, automotive, marine, construction, and wind energy. They are responsible for fabricating composite parts and components used in a wide range of applications, such as aircraft structures, automotive body panels, boat hulls, wind turbine blades, and construction materials.

What are the educational requirements to become a Mottle Lay Up Operator?

While there are no formal educational requirements to become a Mottle Lay Up Operator, many employers prefer candidates with a high school diploma or equivalent. Some employers may also require candidates to have experience in composite fabrication or a related field.

What are the typical salary ranges for Mottle Lay Up Operators?

The salary ranges for Mottle Lay Up Operators can vary depending on their experience, skills, and location. According to Indeed, the average salary for a Mottle Lay Up Operator in the United States is around \$25 per hour.