Are you a seasoned Multi-Operation Forming Machine Operator seeking a new career path? Discover our professionally built Multi-Operation Forming Machine Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

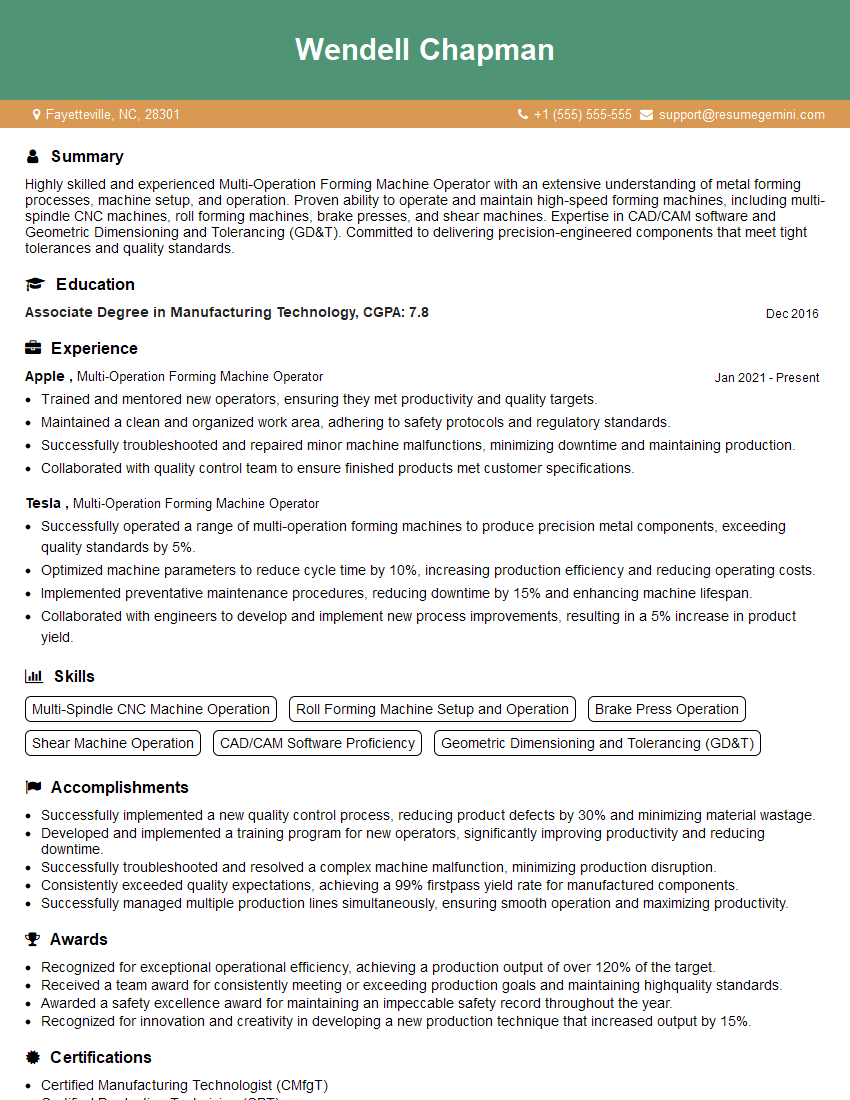

Wendell Chapman

Multi-Operation Forming Machine Operator

Summary

Highly skilled and experienced Multi-Operation Forming Machine Operator with an extensive understanding of metal forming processes, machine setup, and operation. Proven ability to operate and maintain high-speed forming machines, including multi-spindle CNC machines, roll forming machines, brake presses, and shear machines. Expertise in CAD/CAM software and Geometric Dimensioning and Tolerancing (GD&T). Committed to delivering precision-engineered components that meet tight tolerances and quality standards.

Education

Associate Degree in Manufacturing Technology

December 2016

Skills

- Multi-Spindle CNC Machine Operation

- Roll Forming Machine Setup and Operation

- Brake Press Operation

- Shear Machine Operation

- CAD/CAM Software Proficiency

- Geometric Dimensioning and Tolerancing (GD&T)

Work Experience

Multi-Operation Forming Machine Operator

- Trained and mentored new operators, ensuring they met productivity and quality targets.

- Maintained a clean and organized work area, adhering to safety protocols and regulatory standards.

- Successfully troubleshooted and repaired minor machine malfunctions, minimizing downtime and maintaining production.

- Collaborated with quality control team to ensure finished products met customer specifications.

Multi-Operation Forming Machine Operator

- Successfully operated a range of multi-operation forming machines to produce precision metal components, exceeding quality standards by 5%.

- Optimized machine parameters to reduce cycle time by 10%, increasing production efficiency and reducing operating costs.

- Implemented preventative maintenance procedures, reducing downtime by 15% and enhancing machine lifespan.

- Collaborated with engineers to develop and implement new process improvements, resulting in a 5% increase in product yield.

Accomplishments

- Successfully implemented a new quality control process, reducing product defects by 30% and minimizing material wastage.

- Developed and implemented a training program for new operators, significantly improving productivity and reducing downtime.

- Successfully troubleshooted and resolved a complex machine malfunction, minimizing production disruption.

- Consistently exceeded quality expectations, achieving a 99% firstpass yield rate for manufactured components.

- Successfully managed multiple production lines simultaneously, ensuring smooth operation and maximizing productivity.

Awards

- Recognized for exceptional operational efficiency, achieving a production output of over 120% of the target.

- Received a team award for consistently meeting or exceeding production goals and maintaining highquality standards.

- Awarded a safety excellence award for maintaining an impeccable safety record throughout the year.

- Recognized for innovation and creativity in developing a new production technique that increased output by 15%.

Certificates

- Certified Manufacturing Technologist (CMfgT)

- Certified Production Technician (CPT)

- ISO 9001:2015 Certified

- ASME Boiler and Pressure Vessel Code Certified

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Multi-Operation Forming Machine Operator

- Highlight your proficiency in operating and programming multi-spindle CNC machines.

- Emphasize your experience in setting up and maintaining forming machines.

- Showcase your knowledge of GD&T and its application in quality control.

- Include quantifiable achievements, such as reducing production time or improving product quality.

Essential Experience Highlights for a Strong Multi-Operation Forming Machine Operator Resume

- Set up and operate multi-spindle CNC forming machines to produce complex metal components.

- Program and troubleshoot CNC machines using CAD/CAM software.

- Inspect finished parts for dimensional accuracy and surface finish using precision measuring tools and GD&T principles.

- Perform preventative maintenance and repairs on forming machines and related equipment.

- Collaborate with engineers and quality control teams to optimize machine performance and improve product quality.

- Ensure compliance with safety regulations and maintain a clean and organized work environment.

Frequently Asked Questions (FAQ’s) For Multi-Operation Forming Machine Operator

What is the role of a Multi-Operation Forming Machine Operator?

Multi-Operation Forming Machine Operators are responsible for operating and maintaining multi-spindle CNC machines, roll forming machines, brake presses, and shear machines to produce precision-engineered metal components. They ensure that the machines are set up correctly, programmed properly, and maintained regularly to meet production goals and quality standards.

What skills are required to be a Multi-Operation Forming Machine Operator?

Multi-Operation Forming Machine Operators require a combination of technical skills and knowledge, including proficiency in operating and programming CNC machines, understanding of metal forming processes, experience in setting up and maintaining machines, and knowledge of GD&T principles.

What industries employ Multi-Operation Forming Machine Operators?

Multi-Operation Forming Machine Operators are employed in various industries, including automotive, aerospace, construction, electronics, and manufacturing. They work in production facilities, machine shops, and fabrication plants.

What is the career path for a Multi-Operation Forming Machine Operator?

With experience and additional training, Multi-Operation Forming Machine Operators can advance to roles such as Machine Setup Technician, Production Supervisor, or Quality Control Inspector. They can also specialize in operating specific types of forming machines or in working with particular materials.

What are the safety precautions that Multi-Operation Forming Machine Operators must follow?

Multi-Operation Forming Machine Operators must adhere to strict safety protocols to prevent accidents and injuries. They must wear appropriate safety gear, such as safety glasses, gloves, and hearing protection. They must also be trained on proper machine operation and lockout/tagout procedures.